Understanding which hydraulic fittings correctly mates with an inverted flare thread is crucial for any automotive or hydraulic system. Using the wrong connector can lead to dangerous leaks and system failure, making proper identification paramount for safety and performance.

This guide will demystify the specific fitting types designed to perfectly complement an inverted flare thread. We’ll explore the characteristics of these mating components, ensuring you can confidently choose the right parts for a secure, leak-free connection.

What is an Inverted Flare Thread?

An inverted flare thread refers specifically to the threaded portion of an inverted flare fitting, which is characterized by its internal, or “inverted,” 45-degree conical seat.

This seat is designed to receive and seal against a male tube end that has been flared outwards at the same 45-degree angle. Found primarily in automotive applications like brake lines and fuel systems, the threads, usually UN/UNF (Unified National Fine) parallel threads, work in conjunction with the inverted conical seat to create a secure, metal-to-metal, leak-proof connection when tightened.

How Do Inverted Flare Fittings Work?

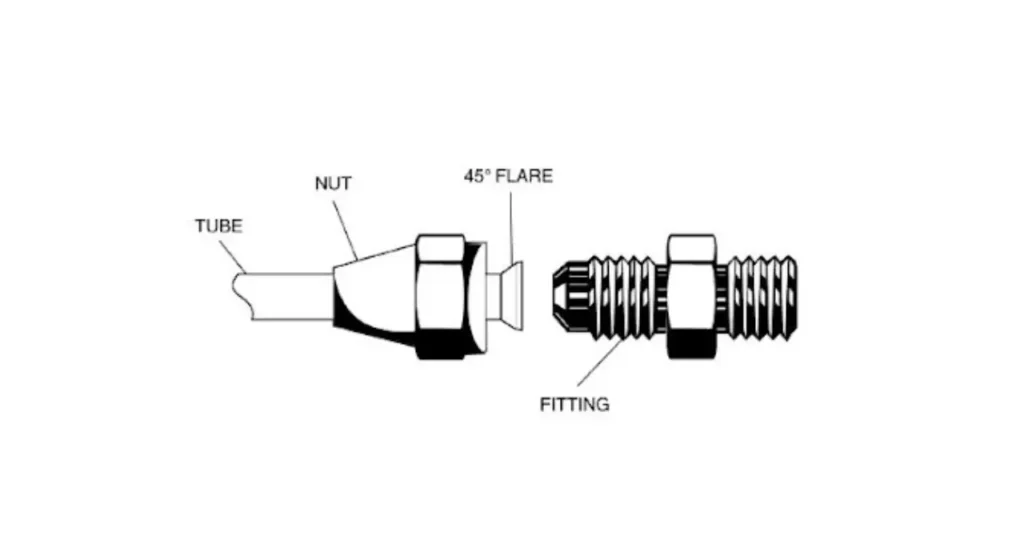

Inverted flare fittings create a secure, metal-to-metal seal through a specific compression mechanism. The system comprises a male tube end that has been flared outwards to a 45-degree angle, a tube nut that slides over this flared tube, and the inverted flare fitting body itself, which features an internal 45-degree conical seat and external threads.

When the tube with its flare and nut is inserted into the fitting body and the nut is tightened, it pushes the flared end of the tube firmly into the fitting’s corresponding inverted conical seat. This compression forces the soft metal of the flared tube to conform precisely to the contours of the fitting’s seat, creating a tight, leak-proof seal that can withstand medium to high pressures, making them highly reliable for applications like automotive brake lines.

Inverted Flare Thread Uses

Inverted flare threads are widely utilized across various industries for creating robust, leak-free fluid connections. Their reliable metal-to-metal seal makes them a preferred choice in demanding environments where safety and performance are paramount.

- Automotive Brake Lines: This is their most common and critical application, providing secure and high-pressure connections for hydraulic brake fluid.

- Automotive Fuel Lines: Used for fuel delivery systems, ensuring a tight seal against volatile fuels.

- Transmission Cooler Lines: Often found in automatic transmission systems for transferring cooling fluid.

- Power Steering Lines: Used in some power steering systems for hydraulic fluid transfer.

- Hydraulic Systems (Lower Pressure): Employed in certain general hydraulic applications that do not require the extremely high pressures handled by JIC fittings.

- HVAC/Refrigeration (specific cases): Can be found in some specialized refrigeration or air conditioning applications, though less common than 45-degree SAE flares.

What Fitting Mates With an Inverted Flare Thread?

An inverted flare thread, characterized by its internal 45-degree conical seat, primarily mates with a male tube end that has been flared outwards at the same 45-degree angle. This flared tube end, often secured by a tube nut that slips over the tube, is inserted into the inverted flare fitting.

When the tube nut is tightened, it compresses the flared tube end into the inverted conical seat of the fitting body. This creates a secure, metal-to-metal seal, making the connection leak-proof. These fittings are standardized under SAE J512 and are commonly used in automotive brake lines, fuel lines, and other medium-to-high pressure applications.

Here are the fittings and components that mate with an inverted flare thread:

- A Tube with a 45-degree Single Flare: The crucial mating component is the tube itself, which has had its end specially flared outwards to a 45-degree angle. This precisely formed metal surface is what creates the seal.

- A Tube Nut (Sleeve Nut): This nut slides over the tube before the flare is formed. When tightened onto the inverted flare fitting’s male threads, it pushes the flared tube end into the fitting’s internal conical seat, ensuring a secure connection.

- The Inverted Flare Fitting Body: This is the component that contains the inverted flare thread. It has a female internal 45-degree conical seat that the flared tube end presses against, and male threads (usually UN/UNF parallel threads) onto which the tube nut tightens.

Is Inverted Flare the Same as Double Flare?

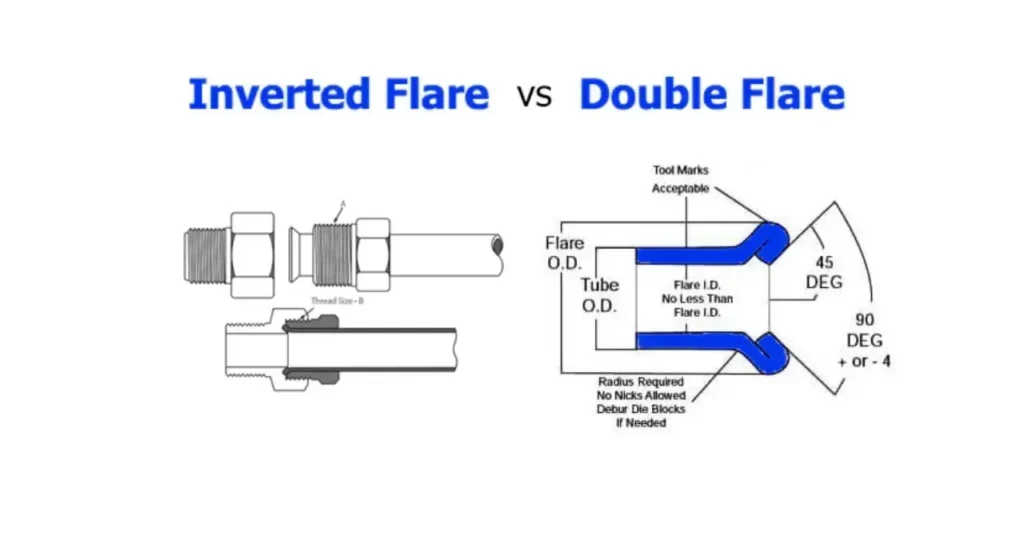

No, an inverted flare is not the same as a double flare, although both are types of 45-degree flares commonly found in automotive applications. The key distinction lies in the method used to form the flare on the end of the tubing, which directly impacts the strength and sealing integrity of the connection. Understanding this difference is crucial for proper and safe system assembly.

An inverted flare (often simply referred to as a single 45-degree flare when formed on a single wall tube) is created by flaring a single layer of the tube outwards. This forms a conical sealing surface that mates with a corresponding internal, or “inverted,” cone within the fitting body. While effective for many medium-pressure applications, this single-wall construction can be more susceptible to cracking or fatigue under severe stress.

In contrast, a double flare involves a two-step process where the end of the tubing is first folded back on itself to create a double-layered wall, and then this reinforced end is flared outwards. This technique results in a much stronger, more resilient sealing surface that is significantly more resistant to cracking, fatigue, and vibration. For this reason, double flares are the standard for critical applications like automotive brake lines.

Conclusion

Correctly identifying the mating fitting for an inverted flare thread is fundamental for any reliable fluid system. This knowledge ensures proper sealing, prevents leaks, and safeguards the integrity of your hydraulic or automotive connections.

By understanding the male inverted flare nut and its compatibility with the female inverted flare seat, you can confidently select the right components. This precision is vital for both safety and the longevity of your applications.

For accurately matched fittings, remember you can get wholesale inverted flare fittings from trusted suppliers like Kingdaflex. Sourcing reliable parts ensures your projects are built to last.