Sandblasting, also known as abrasive blasting, is a powerful and versatile process used to prepare surfaces for a variety of tasks. Whether you’re a professional in construction or an enthusiast restoring an old car, understanding this technique is key to achieving a flawless finish. This guide will walk you through everything you need to know about sandblasting.

We’ll cover how it works, the different types of sandblasting media and equipment you can use, and its most common applications. From safety precautions to best practices, you’ll gain the knowledge to use this powerful tool safely and effectively. Get ready to master the ultimate technique for surface preparation and restoration.

What is a Sandblast?

Sandblasting is a powerful surface preparation and cleaning process that involves forcibly propelling a stream of abrasive material against a surface under high pressure, typically using compressed air.

The “sandblasting” is often used as a general name for this technique, even though modern practices rarely use actual sand due to health risks. Instead, a wide variety of abrasive media are used, such as glass beads, steel grit, walnut shells, and aluminum oxide. This process is highly effective for smoothing a rough surface, roughening a smooth one, shaping a surface, or removing contaminants like rust, paint, and grime.

What Does Sandblasting Do?

What is sandblasting used for?

Sandblasting, or abrasive blasting, is a process used to manipulate the surface of a material by forcibly propelling a stream of media against it under high pressure. Its primary function is to change the condition of a surface, whether by cleaning it, smoothing it, or roughening it. This method is highly effective for tasks that require the removal of stubborn contaminants or the preparation of a surface for a new coating.

- Cleaning and Contaminant Removal: Sandblasting is a powerful way to strip away tough contaminants like rust, scale, old paint, and dirt from surfaces. It’s often used on metal, concrete, and brick to restore their original condition or prepare them for a new application.

- Surface Preparation and Profiling: One of the most critical functions of sandblasting is creating a “profile” on a surface. The microscopic roughness left behind provides an excellent anchor for new paint, coatings, or adhesives, ensuring a stronger and more durable bond.

- Finishing and Etching: Sandblasting can also be used for cosmetic or artistic purposes. By adjusting the media and pressure, it can be used to create a uniform, matte finish on metal, or to etch intricate patterns into glass, stone, or wood.

How Does Sandblasting Work

Sandblasting is a surface preparation process that uses a blast pot to hold abrasive media and an air compressor to propel it at a high velocity through a nozzle. The high-speed impact of the media physically strips away rust, paint, and contaminants from a surface.

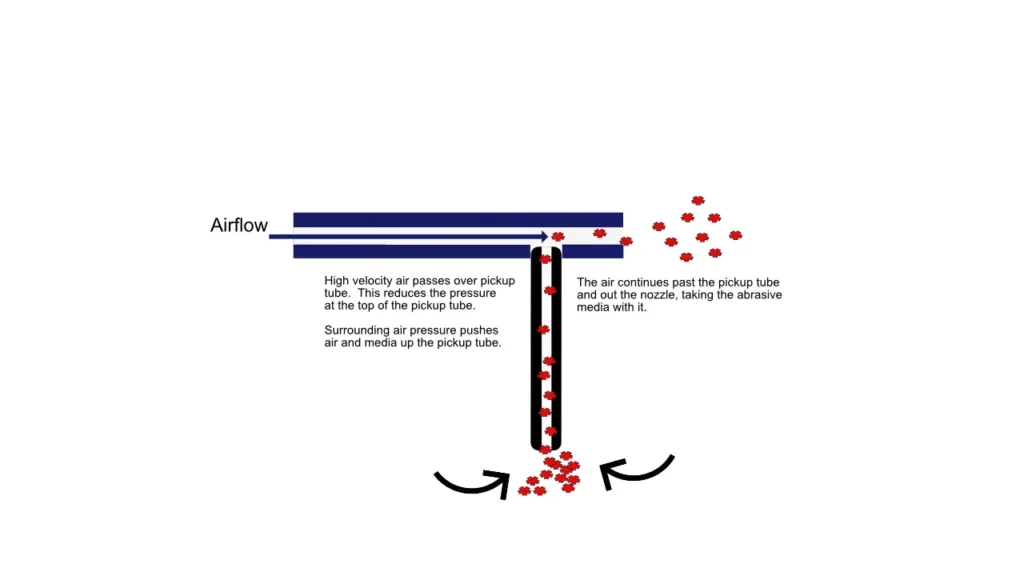

This process is highly effective for cleaning, smoothing, or roughening a surface to prepare it for a new coating. The method of delivery can vary between “suction” and “pressure” blast systems, but the core principle of using compressed air to accelerate media remains the same.

- Compressed Air Source: A powerful air compressor provides the high-pressure air that serves as the propellant. Without a sufficient and consistent air supply, the blasting media won’t have the force needed to effectively clean the surface.

- Abrasive Media: This is the material that does the actual work. It’s stored in a sealed container called a blast pot and is chosen based on the surface material and the desired outcome, whether it’s aggressive stripping or gentle cleaning.

- Propulsion and Delivery: Air from the compressor enters the blast pot, pressurizing it and forcing the abrasive media into the air stream. The mixture then travels through a specially designed sandblast hose to the nozzle, which directs the powerful stream at the target surface.

- Impact and Removal: When the media hits the surface, its high kinetic energy causes a micro-abrasion effect. This impact breaks the bond between the surface and the contaminants, physically knocking them loose and leaving a clean, profiled surface ready for the next step.

What Material is Used for Sandblasting

The term “sandblasting” is a general name for abrasive blasting, but modern practices use a variety of media to suit different materials and desired outcomes. The choice of media is crucial and depends on the surface’s hardness and the type of work being done, from aggressive rust removal to delicate cleaning or etching. These materials are chosen for their specific properties, such as hardness, shape, and recyclability.

- Hard Media: For aggressive tasks like removing heavy rust, paint, and scale from hard surfaces like steel and concrete, materials such as steel grit, aluminum oxide, and silicon carbide are used. These materials are sharp and durable, providing a fast cutting action and creating an excellent surface profile for coatings.

- Soft Media: When working with delicate surfaces like soft metals, wood, or plastics, softer, less-aggressive media are preferred. Options like walnut shells, corn cob grit, plastic abrasives, and glass beads clean surfaces without causing damage or altering the underlying material’s shape. They are ideal for polishing and light cleaning.

- Specialty Media: There are also media with unique properties for specific applications. Sodium bicarbonate (baking soda) is used for “soda blasting” to clean sensitive surfaces without damaging them, as the particles explode on impact. Dry ice blasting uses solid CO2 pellets that sublimate, leaving no residue behind.

What is Needed for Sandblasting

For a basic sandblasting setup, you will need several key pieces of equipment. The process requires a high-pressure stream of air and an abrasive material to clean or shape a surface. The abrasive material, or media, is stored in a pressure vessel before being propelled at the target. Proper safety gear is also critical to protect the operator from flying particles and dust.

The essential equipment includes:

- Air Compressor: This provides the high-pressure air needed to propel the abrasive media.

- Blast Pot (Pressure Vessel): A container that holds the abrasive material and feeds it into the air stream.

- Nozzle: Directs the abrasive media onto the surface you are working on.

- Sandblast Hoses: These are specifically designed for the abrasive demands of sandblasting and connect the various components, such as the air compressor to the blast pot and the blast pot to the nozzle.

- Personal Protective Equipment (PPE): This is essential and includes a blast helmet or hood with an air supply, heavy-duty gloves, and a blast suit or durable clothing to protect your skin from the abrasive particles.

Conclusion

In conclusion, sandblasting is an indispensable technique for surface preparation and restoration, offering unmatched efficiency in removing tough contaminants like rust and old paint. Its ability to create an ideal surface profile for new coatings ensures superior adhesion and long-lasting results. By understanding the different types of media, equipment, and safety measures, you can tackle a wide range of projects with confidence and precision.

Mastering sandblasting is about more than just a powerful tool; it’s about making a strategic choice for a professional finish. The method you choose—whether for a large industrial job or a small-scale repair—determines the quality and durability of your final product. When executed properly, abrasive blasting provides a foundation that is both aesthetically pleasing and structurally sound, guaranteeing success.

For all your sandblasting needs, having the right equipment is critical. At Kingdaflex, we specialize in high-quality wholesale sandblast hoses built for extreme durability and performance. Our hoses are designed to handle the toughest jobs, ensuring a safe and reliable transfer of abrasive media. Choose Kingdaflex to equip your operations with the best hoses on the market.