UHMWPE chemical hoses are specialized conduits designed to transport a wide array of corrosive chemicals and solvents safely and efficiently. Their exceptional chemical resistance and durability make them indispensable in industries dealing with aggressive fluids. Understanding their properties, applications, and benefits is crucial for ensuring safe and efficient chemical transfer operations.

This blog post will delve into the characteristics of UHMWPE chemical hoses, exploring their construction, advantages, and diverse industrial applications. We’ll cover the materials used, the types of chemicals they can handle, and the key factors to consider when selecting the right UHMWPE hose for your specific needs, providing you with essential knowledge for safe and efficient chemical handling.

What is UHMWPE?

UHMWPE stands for Ultra-High-Molecular-Weight Polyethylene. It’s a subset of thermoplastic polyethylene, but with an exceptionally high molecular weight. This unique molecular structure gives UHMWPE some very distinct and valuable properties.

UHMWPE chemical hose is a type of polyethylene hose with an exceptionally high molecular weight, providing outstanding strength and chemical resistance. This material’s unique properties make it an ideal choice for crafting chemical hoses designed to handle corrosive substances.

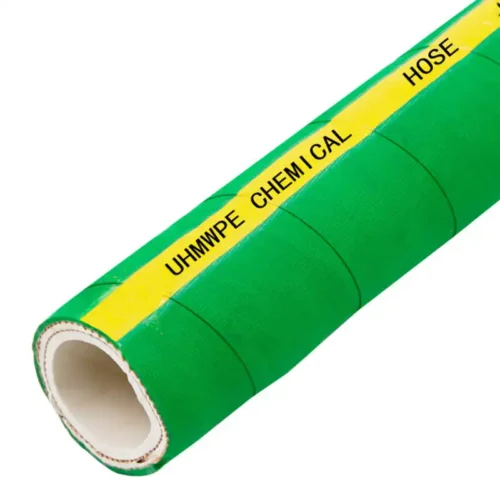

UHMWPE Chemical Transfer Hose

Let’s delve into more detail about three types of UHMWPE Chemical Hoses: UHMWPE Chemical Discharge Hose, UHMWPE Chemical S&D Hose, and UHMWPE Chemical S&D Corrugated Hose:

UHMWPE Chemical Discharge Hose

UHMWPE Chemical Discharge Hose is a type of hose specifically designed for efficiently discharging chemicals from one point to another. Here’s what you need to know about it:

- Design: This hose is typically designed with a smooth, ultra-high-molecular-weight polyethylene (UHMWPE) inner lining. The smooth inner surface minimizes friction, allowing for the smooth and unrestricted flow of chemicals.

- Applications: UHMWPE Chemical Discharge Hoses are commonly used in scenarios where the safe and rapid discharge of chemicals is essential. For instance, these hoses are frequently employed in industrial settings where chemicals need to be pumped out of storage tanks or containers and transported to the desired location, such as during chemical transfer processes.

- Advantages: The key advantage of UHMWPE Chemical Discharge Hoses is their chemical resistance. They are engineered to handle a wide range of corrosive chemicals without suffering from degradation or compromising the quality of the transferred substances. Their smooth interior surface also aids in easy cleaning and maintenance.

UHMWPE Chemical S&D Hose (Suction and Discharge)

UHMWPE Chemical S&D Hose, also known as UHMWPE Chemical Suction and Discharge Hose, is a versatile hose designed for both suction and discharge applications involving chemicals. Here’s what sets it apart:

- Design: Like the discharge hose, the UHMWPE Chemical S&D Hose features an inner lining made of UHMWPE. This lining ensures chemical compatibility and resistance to corrosion. Additionally, it is reinforced with high-strength textile plies and a helical wire for added durability and flexibility.

- Applications: This hose is used in scenarios where chemicals not only need to be discharged but also suctioned or pumped from one location to another. For example, it’s employed in chemical industries for transferring chemicals from storage tanks to processing equipment and vice versa. The hose’s dual functionality makes it a valuable asset in various chemical-handling processes.

- Advantages: UHMWPE Chemical S&D Hoses combine the benefits of both suction and discharge capabilities with the chemical resistance of UHMWPE. They can handle a wide array of corrosive substances safely and efficiently. Additionally, the reinforcement enhances the hose’s durability and flexibility, making it suitable for demanding industrial applications.

UHMWPE Chemical S&D Corrugated Hose

UHMWPE Chemical S&D Corrugated Hose is a specialized variation of the UHMWPE Chemical S&D Hose, characterized by its corrugated design. Here’s what makes it unique:

- Design: This hose features a corrugated inner lining made of UHMWPE. The corrugations or ridges on the inner surface provide additional flexibility without compromising the hose’s chemical resistance. Like the standard S&D hose, it is also reinforced with textile plies and a helical wire for strength and durability.

- Applications: The corrugated design of this hose makes it particularly suitable for applications where flexibility is crucial, such as when navigating tight bends or curves. It is commonly used in scenarios where chemicals need to be both suctioned and discharged while maintaining a high degree of flexibility.

- Advantages: The key advantage of the UHMWPE Chemical S&D Corrugated Hose is its flexibility, which allows it to handle complex routing without kinking or collapsing. It retains the chemical resistance of UHMWPE, ensuring the safe handling of corrosive chemicals. The reinforcement ensures it can withstand the rigors of industrial use.

These three types of UHMWPE Chemical Hoses cater to different industrial needs. UHMWPE Chemical Discharge Hose is ideal for efficiently moving chemicals from one point to another. UHMWPE Chemical S&D Hose serves dual purposes, allowing for both suction and discharge of chemicals.

UHMWPE Chemical S&D Corrugated Hose adds flexibility to the equation, making it suitable for applications that require maneuverability around bends and curves while maintaining chemical resistance. These hoses are essential tools in industries that demand safe and efficient chemical handling.

Why Choose UHMWPE Chemical Hoses?

UHMWPE chemical hose is a type of chemical hose that can be applied widely. These hoses are specifically designed for the safe and efficient transfer of chemicals. Here’s why they stand out:

Chemical Resistance: UHMWPE is highly resistant to a wide range of chemicals, acids, and bases, ensuring the integrity of both the hose and the transferred substance.

Durability: The high molecular weight of UHMWPE makes these hoses incredibly durable, capable of withstanding challenging industrial environments.

Smooth Interior: The smooth inner surface of UHMWPE hoses minimizes friction, ensuring the smooth flow of chemicals without clogs or contamination.

Flexibility: Despite their durability, UHMWPE hoses remain flexible, allowing for easy maneuverability and installation.

Molecular Weight: What sets UHMWPE apart is its extraordinarily high molecular weight. This means that the individual polyethylene chains in this material are incredibly long, creating a dense and interconnected network of molecules. In practical terms, the molecular weight of UHMWPE can exceed 3 million g/mol, whereas regular polyethylene typically has a molecular weight of around 20,000 g/mol. This high molecular weight gives UHMWPE its unique properties.

Strength: UHMWPE is renowned for its exceptional strength, both in terms of tensile strength (resistance to stretching) and impact strength (resistance to sudden shocks or impacts). Despite its lightweight nature, it is incredibly tough and can withstand heavy loads and stress without deformation or breakage.

Chemical Resistance: UHMWPE exhibits remarkable resistance to a wide range of chemicals, acids, and bases. This makes it an ideal material for applications where contact with corrosive substances is common, such as chemical hoses.

Low Friction: The molecular structure of UHMWPE results in a very low coefficient of friction. In practical terms, this means that UHMWPE surfaces are exceptionally slippery. This property is valuable in many applications, including industrial equipment where reduced friction is crucial.

Abrasion Resistance: UHMWPE is highly resistant to abrasion, which means it can withstand wear and tear over time, even in harsh environments. This makes it suitable for applications where materials come into contact with abrasive surfaces.

Self-Lubrication: Due to its low friction properties, UHMWPE is often considered self-lubricating. This means it can continue to operate smoothly without the need for additional lubrication, reducing maintenance requirements.

FDA Approval: UHMWPE is FDA-approved for certain applications, making it safe for use in food-related industries.

Applications of UHMWPE Chemical Hoses

Let’s explore in more detail the various applications where UHMWPE Chemical Hoses are commonly used due to their unique properties and advantages:

Chemical Manufacturing

In the realm of chemical manufacturing, UHMWPE Chemical Hoses play a pivotal role. These hoses are utilized to transfer raw materials, intermediate products, and finished chemicals safely and efficiently. Chemical manufacturing often involves the use of highly corrosive substances, and the exceptional chemical resistance of UHMWPE ensures that these hoses maintain their integrity, preventing leaks and contamination. Whether it’s transporting acids, bases, solvents, or other chemicals, UHMWPE Chemical Hoses are a reliable choice.

Pharmaceuticals

The pharmaceutical industry demands precise and controlled processes, especially when handling potent and often sensitive chemical compounds. UHMWPE Chemical Hoses find extensive use in pharmaceutical companies for the safe transfer of chemicals and active ingredients. The high purity of UHMWPE and its resistance to chemical corrosion make these hoses ideal for maintaining the integrity of pharmaceutical products, ensuring that they reach their destination without any contamination.

Food and Beverage

The food and beverage industry relies on UHMWPE Chemical Hoses to maintain the quality and safety of their products. These hoses are designed to handle a variety of liquids, including acids, syrups, flavorings, and more, without compromising hygiene or taste. UHMWPE is a food-grade material, meeting strict regulatory standards, making it a suitable choice for industries where the utmost care in handling fluids is essential.

Water Treatment

Water treatment plants depend on the precise handling of chemicals for processes such as purification and disinfection. UHMWPE Chemical Hoses ensure the safe transfer of various chemicals, including chlorine, flocculants, and coagulants, without the risk of contamination or chemical reactions. The durability and chemical resistance of these hoses make them a reliable choice for maintaining water quality.

Petrochemical Industry

In the petrochemical sector, where the transfer of volatile and often hazardous substances like fuels, solvents, and chemicals is common, UHMWPE Chemical Hoses are indispensable. These hoses offer a level of safety and reliability crucial to handling these substances without incidents. They resist chemical corrosion and maintain their structural integrity, even in challenging environments.

Mining and Minerals Processing

In mining and minerals processing, abrasive materials and corrosive chemicals are part of everyday operations. UHMWPE Chemical Hoses are employed to transport acids, slurry, and other substances safely. Their abrasion resistance ensures longevity even in harsh mining conditions.

Oil and Gas Industry

The oil and gas industry involves the transfer of a wide range of fluids, from crude oil to specialized chemicals. UHMWPE Chemical Hoses provide a reliable solution for this sector, where safety, durability, and chemical resistance are paramount. They prevent leaks and ensure the efficient flow of substances, reducing downtime and maintenance costs.

In essence, UHMWPE Chemical Hoses are versatile and find applications in numerous industries where the safe, efficient, and contamination-free transfer of fluids is essential. Their unique combination of properties, including chemical resistance, durability, and low friction, makes them a top choice for professionals seeking reliable fluid transfer solutions in demanding environments.

Advantages of UHMWPE Chemical Hose

When it comes to industrial fluid transfer, UHMWPE Chemical Hoses offer numerous advantages that set them apart from other alternatives:

Enhanced Safety

Safety is a paramount concern in industries that handle chemicals and potentially hazardous substances. UHMWPE Chemical Hoses are engineered with safety in mind. Their exceptional chemical resistance ensures that they do not react with the substances they transport. This chemical compatibility prevents leaks, spills, and the potential for accidents, safeguarding both personnel and the environment.

Chemical Compatibility

One of the standout features of UHMWPE Chemical Hoses is their remarkable chemical compatibility. These hoses can safely transport a wide range of corrosive chemicals, acids, bases, and solvents without the risk of degradation or contamination. This compatibility is essential in maintaining the purity and integrity of the transferred substances.

Longevity

UHMWPE Chemical Hoses are known for their exceptional durability. Their high molecular weight and resistance to chemical corrosion mean that they have a longer lifespan compared to traditional hoses. This longevity translates to reduced downtime and lower maintenance costs for industrial operations, contributing to cost savings in the long run.

Easy Cleaning

The smooth interior surface of UHMWPE Chemical Hoses offers a significant advantage when it comes to maintenance. This smoothness minimizes the risk of chemical residue build-up inside the hose. As a result, cleaning and flushing the hoses is a straightforward process, ensuring that they remain in optimal condition for longer periods.

Flexibility

Despite their robustness and durability, UHMWPE Chemical Hoses maintain flexibility. This flexibility makes them easy to maneuver and install in industrial settings. Whether you need to route these hoses through complex systems or in tight spaces, their flexibility simplifies the installation process.

Reduced Maintenance Costs

The combination of longevity, chemical resistance, and easy cleaning leads to reduced maintenance costs. UHMWPE Chemical Hoses require less frequent replacement and maintenance compared to traditional hoses. This not only saves money but also minimizes the disruption to operations caused by maintenance downtime.

Environmental Protection

The chemical compatibility and safety of UHMWPE Chemical Hoses extend to protecting the environment. By preventing leaks and spills of hazardous chemicals, these hoses contribute to environmental conservation and compliance with environmental regulations.

Versatility

UHMWPE Chemical Hoses are versatile and find applications in a wide range of industries, including chemical manufacturing, pharmaceuticals, food and beverage, water treatment, petrochemicals, mining, and more. Their adaptability to different environments and substances makes them a valuable asset in various industrial settings.

In summary, UHMWPE Chemical Hoses offer a multitude of advantages, including enhanced safety, exceptional chemical compatibility, longevity, ease of cleaning, flexibility, reduced maintenance costs, environmental protection, and versatility. These hoses are the go-to choice for professionals seeking reliable and efficient solutions for the safe transfer of chemicals and fluids in industrial operations.

How do UHMWPE Chemical Hoses resist chemical corrosion?

UHMWPE Chemical Hoses resist chemical corrosion due to the high molecular weight of the material, which provides excellent chemical resistance.

Are these hoses suitable for transferring highly volatile chemicals?

Yes, UHMWPE Chemical Hoses are designed to handle highly volatile and corrosive chemicals safely.

Can UHMWPE hoses be used for high-temperature applications?

While UHMWPE itself has a high melting point, it’s essential to check the specific temperature range of the hose to ensure it suits your application.

Are these hoses suitable for food-grade applications?

Yes, UHMWPE hoses are often used in food and beverage processing because they are food-grade and meet strict hygiene standards.

How often should UHMWPE hoses be inspected for wear and tear?

Regular inspections are recommended to ensure the hoses remain in good condition. The frequency of inspections may vary depending on the application and environmental factors.

Can UHMWPE hoses be repaired if damaged?

In most cases, damaged UHMWPE hoses can be repaired, but it’s crucial to consult the manufacturer or a professional for proper assessment and repairs.

Conclusion

In conclusion, UHMWPE chemical hoses stand as a superior choice for industries demanding robust chemical transfer solutions. Their exceptional chemical resistance, durability, and flexibility ensure safe and efficient fluid handling. Understanding the specific properties and applications of these hoses is crucial for optimizing performance and minimizing risks in chemical processing environments.

The unique characteristics of UHMWPE, coupled with advanced hose construction, make these hoses a reliable asset for conveying a wide array of aggressive chemicals. Proper selection and maintenance of UHMWPE hoses contribute significantly to operational safety and longevity, safeguarding both equipment and personnel.

For high-quality, reliable chemical hoses, including UHMWPE options, choose Kingdaflex. We offer a comprehensive range of wholesale solutions tailored to your specific chemical transfer needs. Contact us today to quote your industrial chemical hoses and ensure your operations run smoothly and safely.