When working with brake lines or hydraulic systems, distinguishing between inverted flare and double flare fittings is critical. Although similar, their unique designs and sealing methods make them distinct and non-interchangeable, impacting safety and performance.

This guide will illuminate the key differences between these two common flare types. Understanding their construction, advantages, and specific applications will help you choose the correct fitting for a secure and reliable connection every time.

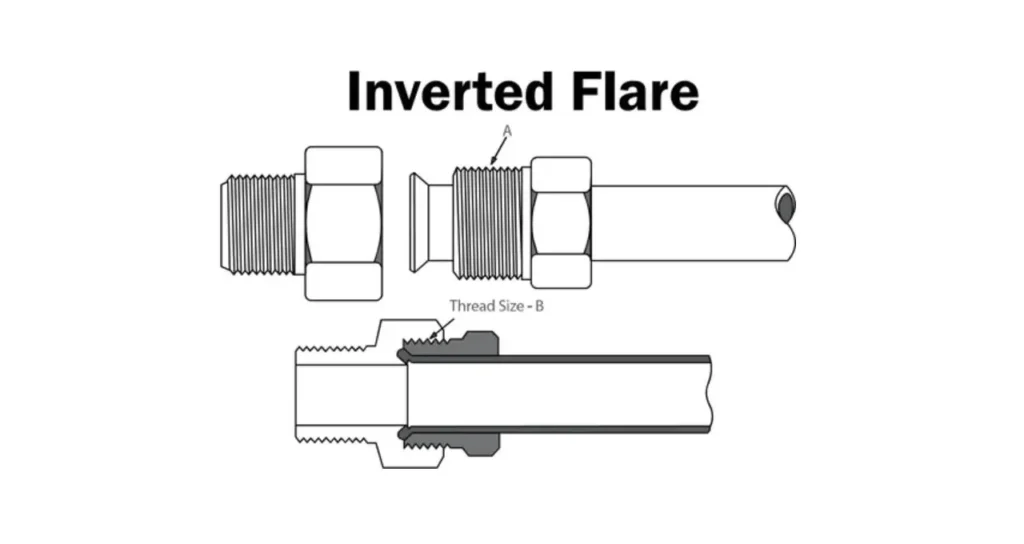

What is Inverted Flare

An inverted flare fitting is a type of tube fitting commonly used in automotive brake lines, fuel systems, and other medium to high-pressure fluid transfer applications.

It features a male end with a 45-degree flare that seats into a female end with a corresponding internal, or “inverted,” conical seat. This design creates a robust, metal-to-metal seal when the nut is tightened, offering excellent resistance to leaks and vibrations, which is crucial for safety-critical systems.

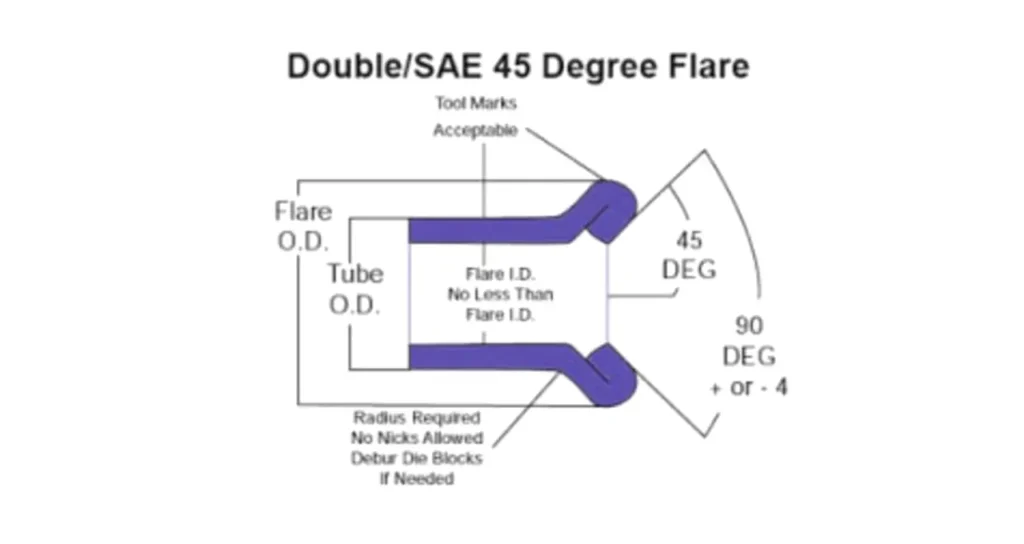

What is Double Flare

A double flare is a specific type of tube end preparation predominantly used for automotive brake lines and other medium-pressure fluid systems.

Unlike a single flare, which involves only one layer of tubing flared outwards, a double flare folds the end of the tubing back on itself before flaring it. This creates a stronger, two-layered, seamless conical sealing surface that is more resistant to cracking and fatigue, enhancing the integrity and reliability of the connection.

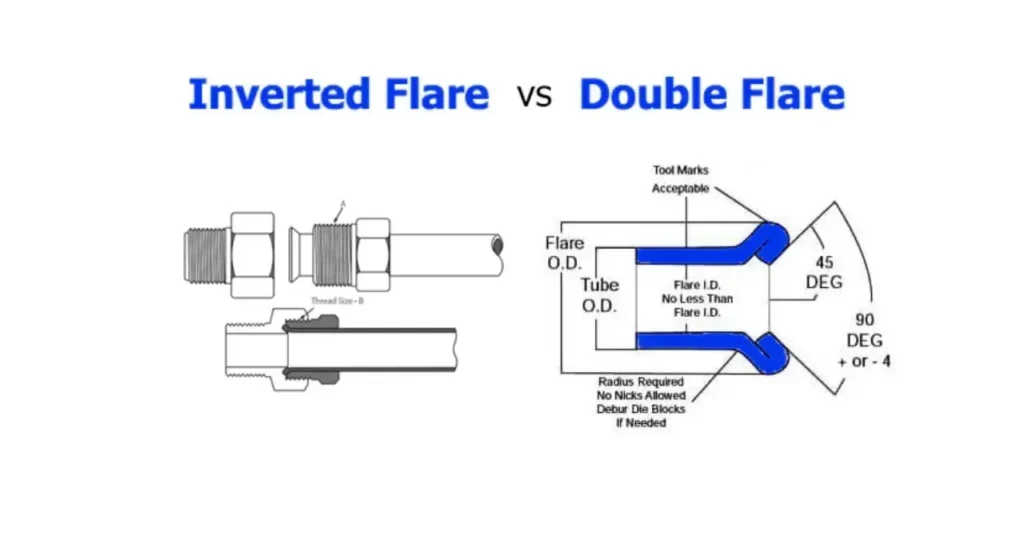

Inverted Flare vs Double Flare

Understanding inverted flare vs. double flare is crucial for automotive and hydraulic projects. Though both create metal-to-metal seals, their distinct formation and sealing geometry impact safety and performance. This guide illuminates their key differences.

Tube End Preparation

An inverted flare is created directly from a single wall of tubing, flared outwards to a 45-degree angle. This simple flare is formed using a specific flaring tool, which pushes the tube material outwards to create the conical sealing surface without folding.

A double flare involves a two-step process where the end of the tube is first folded back upon itself, creating a two-layer wall, and then this folded end is flared outwards. This technique significantly strengthens the flare and prevents cracking.

Sealing Mechanism

The inverted flare creates its seal when the male (flared tube end) mates with the female’s internal, inverted conical seat. The compression from tightening the nut forces the single-wall flare into the fitting, achieving a robust metal-to-metal seal.

The double flare’s sealing mechanism is similar, but its two-layered conical surface provides enhanced sealing integrity. When compressed against the fitting’s seat, the folded material offers a more resilient and uniform contact area, minimizing potential leak paths.

Strength/Durability

Inverted flares are generally strong enough for many standard applications, particularly in older automotive brake lines. However, being a single-wall flare, they can be more susceptible to cracking or fatigue over time, especially under severe vibration or repeated stress.

Double flares offer superior strength and durability due to their reinforced, folded construction. This two-layered design makes them highly resistant to stress fractures, vibration fatigue, and crushing, providing a more reliable and longer-lasting connection for critical systems.

Reusability

While it’s technically possible to reuse inverted flare fittings if no damage occurs, it’s generally not recommended. The single-wall flare can easily deform or crack with repeated tightening and loosening, compromising the seal’s integrity and safety.

Double flare connections are typically more forgiving and reusable than single inverted flares, provided the flare itself remains undamaged. Their stronger construction means they better withstand disassembly and reassembly, maintaining a reliable seal over multiple uses.

Common Applications

Inverted flare fittings are commonly found in older and some modern automotive brake, fuel, and transmission cooler lines. Their widespread use reflects their historical reliability in many medium-pressure applications, though double flares are gaining prevalence for safety-critical systems.

Double flares are now standard for most modern automotive brake lines due to their enhanced safety and durability. They are also preferred for other critical fluid transfer systems where high pressure, vibration, and long-term reliability are paramount considerations for engineered solutions.

Here is a comparison table summarizing the differences:

| Feature | Inverted Flare (Single Wall) | Double Flare (Double Wall) |

| Tube Prep. | Single wall flared outwards | Tube folded back, then flared outwards |

| Sealing Method | Metal-to-metal, single-wall contact | Metal-to-metal, reinforced two-wall contact |

| Strength | Good for standard use, susceptible to fatigue | Superior; highly resistant to cracks/fatigue |

| Reusability | Generally not recommended for reuse | More forgiving; generally reusable if undamaged |

| Applications | Older automotive brake/fuel lines | Modern automotive brake lines, critical systems |

Is an Inverted Flare the Same as a Double Flare?

No, an inverted flare is not the same as a double flare, although both are types of 45-degree flares commonly found in automotive applications like brake lines. The fundamental difference lies in how the tube end is prepared and consequently, the structure of the flared sealing surface. An inverted flare is formed by flaring a single wall of tubing outwards.

Conversely, a double flare involves a two-step process where the tube end is first folded back upon itself to create a reinforced, two-layered wall, which is then flared outwards. This double-wall construction provides superior strength and resistance to cracking, making the double flare generally preferred for more critical and high-vibration applications due to its enhanced durability and reliability.

How to Choose Inverted Flare and Double Flare

When selecting between inverted flare and double flare fittings, your primary consideration should be the application’s specific requirements, particularly concerning pressure, vibration, and safety. Both types create a durable metal-to-metal seal, but their distinct construction methods offer varying levels of robustness and suitability for different fluid transfer systems.

The choice often comes down to the system’s criticality and the environment it operates within. Understanding the nuances of each flare’s formation and performance characteristics ensures you pick the most appropriate fitting, guaranteeing long-term reliability and preventing potential failures.

- Application & Pressure: For high-pressure automotive brake lines and safety-critical systems, double flares are generally the industry standard due to their superior strength and resistance to cracking under stress and vibration. Inverted flares might be found in older vehicles or less demanding applications.

- Durability & Fatigue Resistance: Double flares offer significantly enhanced durability and fatigue resistance compared to single-wall inverted flares. The folded-over tube end provides a reinforced sealing surface that is much less prone to cracking over time, especially in dynamic environments.

- Tube Material: Consider the type of tubing being used. While both can be formed on various materials like copper-nickel or steel, the double flaring process is crucial for preventing tube collapse or damage with thinner-walled or softer tubing, making the double flare more versatile for modern lines.

- Installation Difficulty & Tools: Creating a double flare requires a specialized double flaring tool and a more precise, two-step process, which can be more complex and time-consuming than forming a single inverted flare. Ensure you have the correct tools and expertise for the chosen type.

- OEM vs. Aftermarket: When repairing or replacing lines, always match the original equipment manufacturer (OEM) flare type. Mismatching inverted and double flares will lead to leaks and unsafe connections. Aftermarket solutions also usually specify which flare type they are compatible with.

Conclusion

Mastering the distinctions between inverted flare and double flare fittings is essential for ensuring robust and safe connections, particularly in critical applications like automotive brake lines. Choosing the correct type prevents system failures and enhances reliability.

Your understanding of their unique designs and the specific flaring processes involved will empower you to make informed decisions. This knowledge ensures optimal performance and compatibility within your hydraulic or fluid transfer systems.

For reliable inverted flare and double flare fittings that meet high standards, consider where to get wholesale from trusted suppliers. Sourcing quality components is paramount for project success and long-term durability.