Installing a rubber hose often requires navigating tight spaces and making precise turns. Without the right technique, the hose can easily kink, restricting flow and compromising its integrity. Learning to bend a hose correctly is crucial for any installation.

This guide will walk you through the proper methods to safely and effectively bend a rubber hose. We will cover essential tools and techniques to ensure you get a perfect, kink-free bend every time, maintaining the hose’s performance and safety.

Why Bending Rubber Hoses?

Bending a rubber hose is often a necessary part of the installation process to accommodate the specific layout of a system. Hoses are bent to fit into tight or complex spaces, route around obstacles, and to ensure they connect two points without unnecessary slack. This deliberate bending is crucial for preventing kinking, which can restrict the flow of fluid and compromise the hose’s structural integrity, ultimately leading to premature failure.

- Space Constraints: Hoses are bent to fit into confined areas and to navigate around engine components and other machinery.

- Reduces Stress: Bending the hose properly reduces stress and tension on the end fittings, which prevents leaks and prolongs life.

- Optimizes Flow: A smoothly bent hose with no kinks ensures a consistent, unobstructed flow of fluid or gas for optimal performance.

- Eliminates Slack: Proper bending eliminates excess hose slack, preventing rubbing or abrasion against other components that could cause damage.

How to Bend a Rubber Hose?

Bending a rubber hose properly is crucial to prevent kinking, which can restrict flow and cause damage. The right technique ensures the hose maintains its integrity, flexibility, and performance, even in tight-fit applications.

Step 1: Assess and Prepare the Hose

Before you begin, inspect the hose for any existing damage or wear. Determine the required bend radius and choose a hose with a wall thickness and flexibility suitable for the bend. This preparation ensures the hose can withstand the process.

For best results, warm the hose to make it more pliable, but do not use high heat. A hose that is too cold will be stiff and more prone to cracking. A little warmth makes it easier to work with.

Step 2: Choose Your Bending Method

There are two primary methods for bending a rubber hose safely: using an internal tool or applying controlled heat. The method you choose depends on the hose type and the desired bend. A tool is often preferred for preventing kinks.

For thin-walled hoses, a flexible bending spring is an excellent choice. For thick-walled or stiffer hoses, gentle heat can assist the process. Always choose the least aggressive method to avoid compromising the hose’s structural integrity.

Step 3: Use an Internal Bending Tool

To prevent the hose from collapsing or kinking, insert a flexible bending spring or mandrel into the hose before you begin. This provides essential internal support, helping the hose maintain its circular shape throughout the bending process.

With the tool in place, slowly and carefully form the hose into the desired bend. Apply steady pressure and avoid sharp, forceful movements. Once bent, the spring can be removed by twisting it and pulling it out.

Step 4: Apply Gentle Heat

For stubborn or stiff hoses, you may apply gentle, indirect heat using a heat gun. Move the heat gun continuously along the area to be bent. This softens the rubber and makes it pliable, facilitating the bend without cracking the material.

Never use an open flame or overheat the hose, as this will permanently damage the rubber compound, leading to future failure. The goal is to warm the hose, not to melt it. Overheating compromises the hose’s integrity and safety.

Step 5: Secure and Inspect

Once you have successfully created the bend, secure the hose in place using clamps, brackets, or clips. This ensures the hose maintains its new shape and prevents it from twisting or rubbing against other components during operation.

Finally, inspect the hose for any signs of damage, such as creases, cracks, or bulges. A proper bend should be smooth and uniform. If any damage is present, do not use the hose, as its integrity is compromised.

Rubber Hose Bend Radius

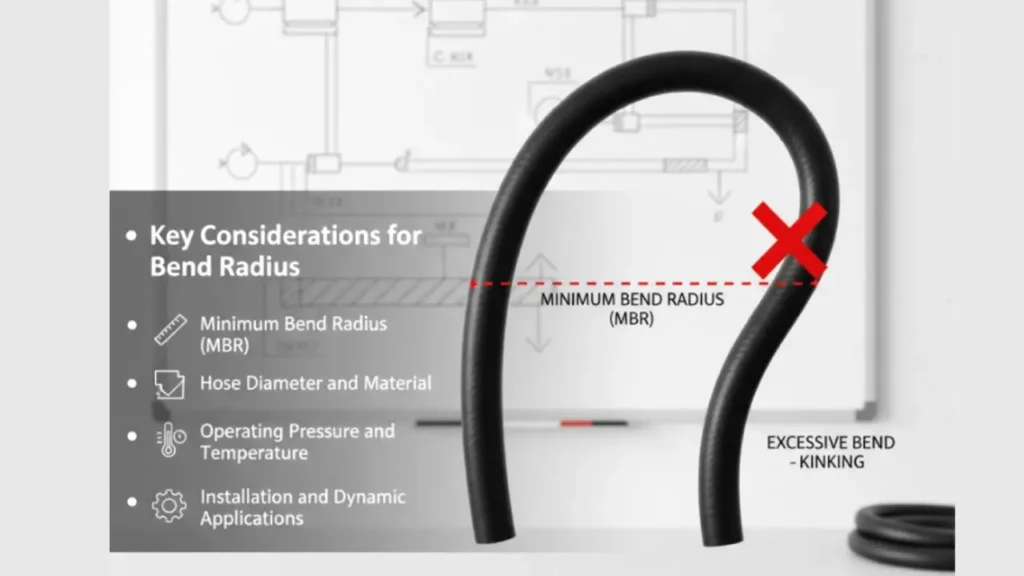

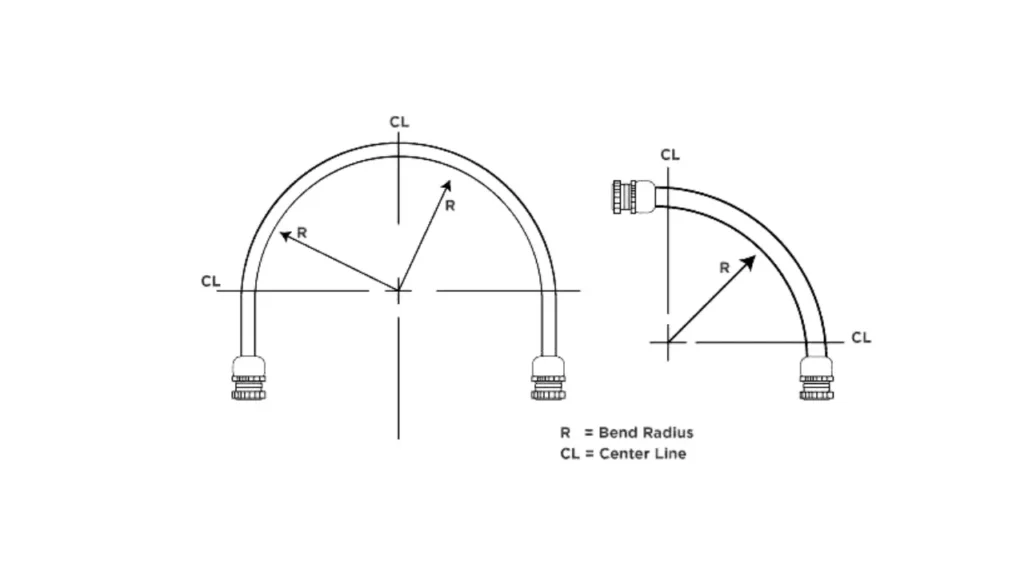

The bend radius of a rubber hose is a crucial specification determining the minimum curve the hose can form without causing damage, kinking, or premature failure. Exceeding this limit compromises the hose’s structural integrity, potentially leading to leaks, reduced flow, or burst.

Minimum Bend Radius (MBR): This is the smallest radius to which a hose can be bent under normal operating conditions. Adhering to the MBR ensures the hose maintains its full pressure rating and expected lifespan. Bending beyond the MBR can induce excessive stress on the hose reinforcement and cover material, severely limiting performance.

Hose Diameter and Material: Larger diameter hoses generally have a proportionally larger required MBR compared to smaller hoses. Furthermore, the type of material used (e.g., standard rubber, thermoplastic, silicone) and the construction, including the reinforcement layers, significantly influence the hose’s inherent flexibility and minimum bending capabilities.

Operating Pressure and Temperature: High operating pressures or extreme temperatures can further reduce the acceptable bend radius. The combination of high internal stress and a tight bend increases the likelihood of hose failure; thus, engineers must select a hose assembly whose design factor accounts for these specific environmental and system variables.

Installation and Dynamic Applications: In fixed installations, the MBR is used to design the routing, ensuring proper flow and longevity. For dynamic applications where the hose is constantly moving, such as on robotics or machinery, a larger bend radius is often recommended to prevent constant flexing fatigue and ensure reliable, long-term operation.

Rubber Hose Bending Angles

When working with rubber hoses, understanding and correctly applying various bending angles is crucial for proper installation and function. These angles are not just arbitrary measurements; they directly impact the hose’s lifespan and performance by preventing kinking and minimizing stress on the material. Proper bending ensures a smooth flow of fluid and reduces the risk of premature failure.

45° Bend: A 45-degree bend is a gentle curve often used for making slight changes in direction. This angle is ideal for routing hoses around minor obstacles or for connecting components that are not directly in line with each other. It puts minimal stress on the hose, ensuring a long service life.

90° Bend: A 90-degree bend is a common and versatile angle for making a sharp turn. It’s frequently used to route a hose around a corner or to connect a component at a perpendicular angle. Hoses designed for this angle have a reinforced structure to prevent kinking.

135° Bend: The 135-degree bend, also referred to as a “long sweep” bend, is a gradual turn that is less common than 45° or 90° bends. It is useful in applications where a smooth, wide turn is required to avoid kinking. This angle minimizes pressure drop and stress on the hose.

180° Bend: A 180-degree bend, or “U-bend,” is used to reverse the direction of a hose. This is often seen in applications where a hose needs to loop back on itself. It is a very tight bend that requires a hose with a flexible and durable design.

Rubber Hose Minimum Bend Radius

The minimum bend radius is the smallest radius a rubber hose can be bent to without causing damage, kinking, or compromising its structural integrity. This is a critical specification provided by the manufacturer, as exceeding this limit can lead to a drastic reduction in the hose’s lifespan and an increased risk of failure. Bending a hose too tightly can cause the inner tube to collapse, restrict flow, and weaken the reinforcement layers, which can result in a catastrophic rupture.

- Inner Diameter: The minimum bend radius is directly proportional to the hose’s inner diameter; a larger diameter hose requires a larger bend radius to prevent kinking and internal collapse.

- Hose Construction: The type of reinforcement, such as a braided or spiral ply, significantly affects the hose’s flexibility and its ability to bend without damaging the structural layers.

- Operating Pressure: Hoses designed for higher pressures typically have a larger bend radius because their thicker walls and robust reinforcement are less flexible and more prone to damage when bent too tightly.

- Material Composition: The flexibility of the rubber compound used for the inner tube and outer cover also plays a role, with some materials being more pliable and allowing for a tighter bend.

Conclusion

In conclusion, bending a rubber hose is a skill that requires precision and the right tools, not brute force. By following the steps outlined in this guide, you can successfully achieve a clean bend without causing dangerous kinks or damaging the hose’s critical internal structure, ensuring its long-term reliability.

Remember, a damaged hose can lead to a sudden and catastrophic failure, so its integrity is paramount. By using the proper techniques, you not only make the installation easier but also guarantee the safety and performance of your entire system. The right method is the best investment you can make.

When starting a new project, trust a hose that is built for superior performance and flexibility. We invite you to get wholesale rubber hoses from our Kingdaflex factory. Our products are engineered for easy handling and maximum durability. Contact us today to find the perfect hose for your needs.