A chemical hose is not merely a conduit; it is a critical safety component engineered for the secure handling of hazardous and corrosive fluids like acids, solvents, and petrochemicals. Understanding its specific applications is paramount for operational integrity across demanding industrial sectors.

This guide will thoroughly examine the essential uses of chemical hoses across various industries, from manufacturing to pharmaceutical production. We highlight how their specialized construction—featuring non-reactive liners and robust reinforcement—makes them indispensable for safety and quality control.

What are Chemical Hoses?

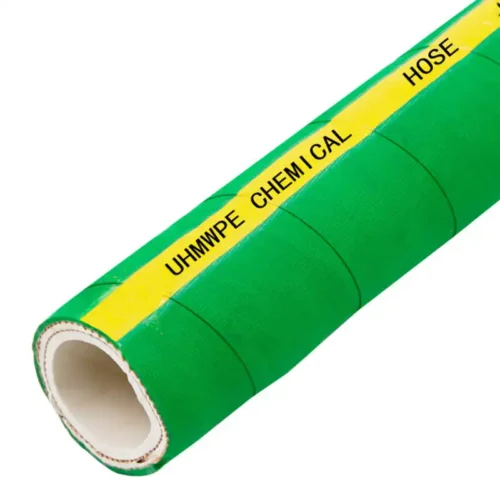

Chemical hoses are highly specialized flexible conduits designed for the safe and reliable transfer of aggressive, corrosive, or high-purity media, including strong acids, alkalis, industrial solvents, and petrochemicals. Their defining characteristic is a non-reactive inner liner, typically made from materials like PTFE (Teflon), UHMWPE (Ultra High Molecular Weight Polyethylene), or specially compounded synthetic rubbers (like EPDM or Nitrile), which prevents the fluid from degrading the hose structure or becoming contaminated.

The construction of these hoses is engineered for safety, featuring multiple layers of textile and steel wire reinforcement to provide exceptional pressure and full vacuum resistance, alongside an external cover that resists external chemical splash, abrasion, and weathering. Used extensively in manufacturing, refining, and pharmaceutical industries, chemical hoses are crucial components that adhere to stringent regulatory standards to prevent leaks and ensure environmental and personnel protection.

What is a Chemical Hose Used For?

A chemical hose is used primarily for the safe and efficient conveyance of various corrosive, hazardous, or high-purity fluids across industrial processes. Its key purpose is to protect workers and the environment by isolating aggressive media, such as strong acids, solvents, and petrochemicals, from the surrounding environment during transfer operations.

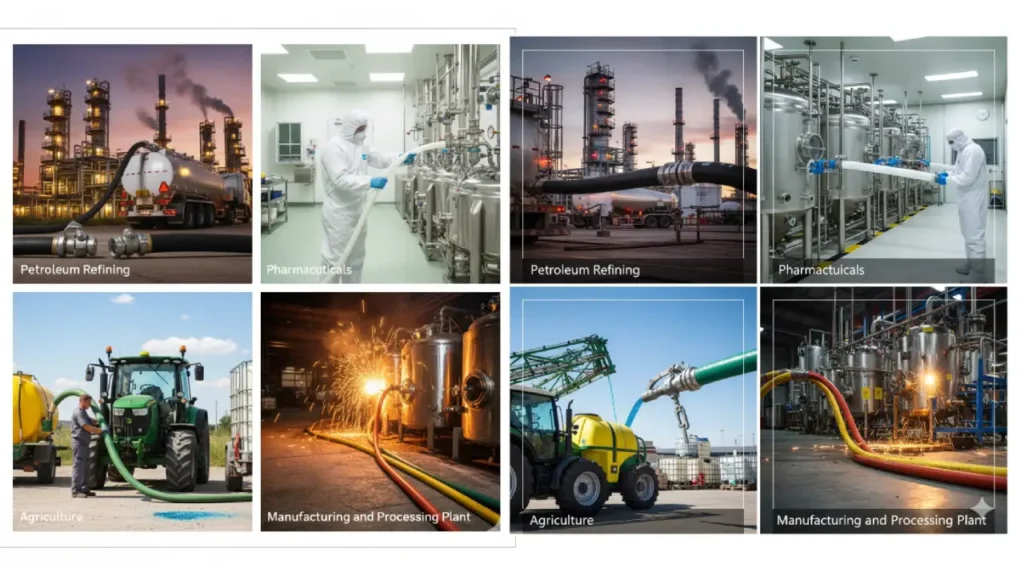

These specialized hoses are essential in manufacturing, pharmaceutical, and refining industries where fluid integrity and safety compliance are paramount. They facilitate bulk loading/unloading, blending, and processing applications, ensuring reliable movement of chemically aggressive substances under various pressure and temperature conditions.

- Bulk Loading and Unloading: Chemical hoses are used at terminals and ports to transfer vast quantities of chemicals to or from storage tanks, railcars, or tanker trucks. This requires robust construction to withstand high flow rates and continuous use, ensuring quick, safe turnaround times during distribution.

- In-Plant Process Lines: They serve as flexible connections within manufacturing facilities, moving reactants, solvents, and finished products between blending vessels, reactors, and filtration units. The hose ensures purity and prevents chemical leaks in the tightly controlled environment of the production floor.

- Dispensing and Sampling: Smaller diameter chemical hoses are utilized for precise dispensing of concentrated chemicals into batches or for drawing samples for quality control testing. The required chemical resistance ensures the sample integrity is maintained, preventing contamination from the hose material itself.

- Tank and Equipment Cleaning: Specialized chemical hoses are required to convey aggressive cleaning agents, such as hot caustics or concentrated acids, used to sterilize processing tanks and pipelines. The hose must handle extreme temperatures and resist breakdown from the highly reactive cleaning solutions effectively.

What Media Can Chemical Hoses Deliver?

Chemical hoses are engineered with specialized, non-reactive liners to safely deliver a vast range of media that would rapidly degrade standard industrial hoses. Their primary function is to maintain fluid integrity while preventing leaks and ensuring the safety of personnel handling corrosive, flammable, or toxic substances.

The specific media a hose can handle is defined by its inner liner material (e.g., PTFE, UHMWPE, or specific synthetic rubber). We must choose the hose based on a chemical compatibility chart that accounts for the fluid’s concentration, temperature, and pressure for safe transfer.

- Strong Acids and Alkalis: They can convey concentrated inorganic acids (like sulfuric, nitric, and hydrochloric acid) and caustic solutions (like sodium hydroxide). PTFE and UHMWPE liners offer robust protection against the highly corrosive nature of these critical processing chemicals.

- Industrial Solvents: Hoses are widely used for transferring organic solvents, including alcohols (methanol, ethanol), ketones (acetone), and aromatics (toluene, xylene). Specialized synthetic rubber liners (like Nitrile or Hypalon) or PTFE prevent the solvents from dissolving the hose structure.

- Petrochemical Products: They safely handle various crude oil derivatives, gasoline, diesel fuels, hydraulic fluids, and lubricating oils. Hoses with oil-resistant liners, such as Nitrile, are essential for maintaining material stability and preventing swelling or permeation during transport and refining.

- High-Purity Media: In pharmaceutical and food-grade applications, chemical hoses convey high-purity water, specialized additives, and sensitive media. Non-leaching, non-contaminating liners like pharmaceutical-grade PTFE are vital for ensuring product quality and adhering to strict industry standards.

Chemical hoses are engineered to deliver a broad spectrum of liquid types, with the specific media dictating the construction and material of the hose liner. The selection of the inner liner is the most crucial step, as it ensures chemical compatibility, prevents hose degradation, and avoids product contamination.

Here is a table detailing the main categories of liquids that chemical hoses are designed to deliver, along with examples and the primary liner materials required for safe transfer:

| Liquid Type | Examples of Media Delivered | Primary Liner Material Required | Key Function of the Liner |

| Strong Inorganic Acids & Alkalis | Sulfuric Acid, Hydrochloric Acid, Nitric Acid, Sodium Hydroxide (Caustic) | PTFE (Teflon), UHMWPE (Polyethylene), Cross-linked Polyethylene (XLPE) | Provides near-universal chemical inertness and corrosion protection against highly reactive substances. |

| Industrial Solvents | Acetone, Toluene, Benzene, Ethanol, Methyl Ethyl Ketone (MEK) | Nitrile (for some solvents), PTFE, Hypalon (CSM) | Resists dissolution, swelling, and permeation by organic solvents and aromatics. |

| Petrochemicals & Fuels | Gasoline, Diesel, Kerosene, Jet Fuel, Lubricating Oils, Hydraulic Fluids | Nitrile (NBR), CPE (Chlorinated Polyethylene), Specialty FKM (Viton) | Provides high resistance to oil and hydrocarbon absorption, preventing breakdown and ensuring flow integrity. |

| High-Purity/Food-Grade Media | Food Additives, Flavorings, Pharmaceutical Solvents, Purified Water (WFI) | Pharmaceutical-Grade PTFE, Silicone (for low pressure), Sanitary UHMWPE | Offers non-leaching, non-contaminating surfaces essential for maintaining product quality and purity standards. |

| Paints, Coatings & Adhesives | Solvent-based paints, Epoxies, Polyurethane coatings, Resins | Nylon, Polyurethane, or specialty NBR | Designed to resist hardening and breakdown from sticky, often abrasive, and fast-curing media. |

Conclusion

The applications of chemical hoses span the critical functions of modern industry, ensuring the safe, compliant, and efficient transfer of dangerous and corrosive media. Whether used for bulk loading in refineries or for precise blending in pharmaceutical labs, their specialized design prevents contamination and safeguards personnel and the environment.

The effectiveness of any chemical transfer operation hinges on selecting a hose with the correct liner, temperature rating, and pressure tolerance, directly matched to the specific media being conveyed. Investing in certified, application-specific hoses minimizes the risk of costly failures and maintains continuous process reliability.

For all your chemical fluid conveyance needs, including highly corrosive acids, solvents, and specialty chemicals, rely on a manufacturer with proven expertise. When it is time to secure your chemical transfer supply chain, get wholesale chemical hoses from our Kingdaflex, ensuring superior performance and uncompromising safety.