A hydraulic system is a technology that uses fluid power to perform work, transmitting energy through pressurized liquids. It powers machinery, vehicles, and industrial equipment efficiently. Understanding hydraulic systems is essential for operators, engineers, and maintenance personnel to ensure safe, reliable, and efficient operations in various industries.

Hydraulic systems consist of components such as pumps, cylinders, valves, and hoses that work together to transfer energy. Proper system design and maintenance are critical to prevent failures, maintain pressure, and ensure smooth performance. This guide explores the fundamentals, types, and applications of hydraulic systems for both beginners and professionals.

What is a Hydraulic System?

A hydraulic system is a technology that uses pressurized fluid to transmit power and perform work. By converting mechanical energy into fluid energy, hydraulic systems can efficiently operate machinery, vehicles, and industrial equipment. These systems are essential in applications requiring high force, precise control, and smooth motion.

Hydraulic systems consist of key components such as pumps, valves, cylinders, and hoses that work together to control and direct fluid flow. Proper design, maintenance, and operation ensure system efficiency, reliability, and safety, making hydraulics a critical part of industries like construction, manufacturing, automotive, and agriculture.

Hydraulic System Components

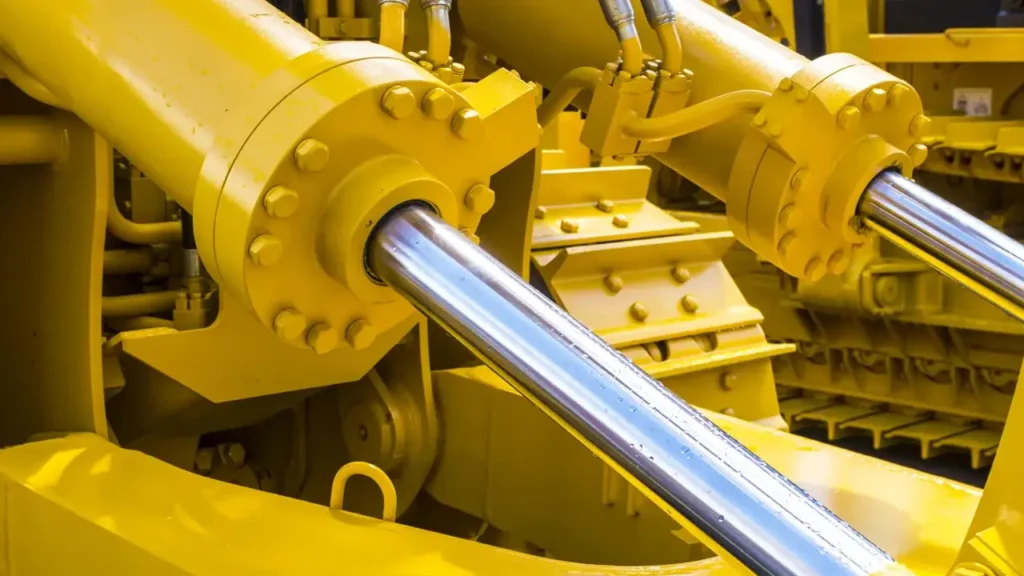

A hydraulic system relies on several key components that work together to transfer fluid power efficiently. Each component plays a critical role in generating, controlling, and directing hydraulic energy. Understanding these parts is essential for designing, maintaining, and troubleshooting hydraulic systems in industrial, automotive, and construction applications.

- Hydraulic Pump: The pump converts mechanical energy into hydraulic energy by pressurizing fluid. We ensure pumps are selected based on flow rate, pressure requirements, and system demands to deliver reliable performance, smooth operation, and efficient energy transfer across various hydraulic applications.

- Hydraulic Cylinder: Cylinders convert fluid pressure into linear mechanical motion. We design cylinders to handle specific loads, stroke lengths, and pressures, ensuring precise, smooth, and powerful movement for lifting, pushing, or positioning tasks in industrial and mobile machinery.

- Hydraulic Valve: Valves control fluid flow, direction, and pressure within the system. We provide valves that allow accurate system control, regulate pressure safely, and enable smooth operation, ensuring both efficiency and protection for all hydraulic components.

- Hydraulic Hose: Hoses connect system components and transport pressurized fluid. We manufacture durable, flexible hoses that resist kinking, pressure, and abrasion, ensuring safe, reliable, and leak-free fluid transfer throughout the hydraulic system under various operational conditions.

- Hydraulic Reservoir: The reservoir stores and cools hydraulic fluid while allowing air to escape. We design reservoirs to maintain fluid supply, prevent contamination, and ensure consistent system pressure, contributing to overall system efficiency, longevity, and safe operation.

What is the Principle of Hydraulic System?

The principle of a hydraulic system is based on Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle allows hydraulic systems to multiply force, control motion, and perform work efficiently in machinery, vehicles, and industrial applications.

- Force Multiplication: Hydraulic systems can amplify small input forces into larger output forces. We design systems to use fluid pressure efficiently, allowing heavy lifting or precise movements with minimal manual effort, enhancing operational performance across industrial and mobile equipment.

- Pressure Transmission: Pressure applied at one point in the system is transmitted uniformly throughout the fluid. We ensure hoses, pumps, and valves maintain integrity, preventing leaks and ensuring reliable and consistent operation under varying loads and conditions.

- Controlled Motion: Hydraulic systems allow precise control of speed and direction. We use valves, cylinders, and actuators to regulate fluid flow, enabling smooth, accurate, and repeatable movements in machinery, vehicles, and industrial equipment.

- Energy Efficiency: By using fluid power, hydraulic systems can transfer energy efficiently with minimal loss. We optimize system design to reduce waste, improve responsiveness, and maintain high performance while supporting demanding operational environments.

How Does Hydraulic System Work?

A hydraulic system works by using pressurized fluid to transmit power from one point to another, converting energy into mechanical motion. This allows heavy machinery and equipment to perform tasks efficiently, with precise control over force, speed, and direction in industrial, automotive, and construction applications.

- Fluid Pressurization: The hydraulic pump pressurizes fluid to create energy. We design pumps to generate consistent pressure, ensuring reliable force transmission, smooth operation, and efficient performance across machinery, vehicles, and industrial equipment under varying load conditions.

- Force Transmission: Pressurized fluid moves through hoses and pipes to actuators like cylinders or motors. We ensure all connections are secure and components are compatible to maintain consistent force, prevent leaks, and deliver precise mechanical output.

- Mechanical Motion Conversion: Cylinders and hydraulic motors convert fluid energy into linear or rotary motion. We select actuators based on load, stroke, and speed requirements to achieve controlled, efficient, and repeatable movements in the system.

- Control and Regulation: Valves regulate flow, pressure, and direction of hydraulic fluid. We implement control systems that allow accurate operation, prevent overpressure, and ensure smooth performance while protecting components from damage.

- Fluid Return and Reservoir: After completing its work, fluid returns to the reservoir for cooling and recirculation. We design reservoirs to maintain fluid levels, reduce contamination, and ensure continuous, reliable operation of the hydraulic system.

Hydraulic Hoses for Hydraulic Systems

Hydraulic hoses are essential components of hydraulic systems, enabling the transfer of pressurized fluid between pumps, valves, cylinders, and motors. They must be durable, flexible, and resistant to pressure, abrasion, and environmental conditions to ensure smooth operation, safety, and longevity of hydraulic machinery and equipment.

- Pressure Resistance: Hydraulic hoses must withstand high pressures without bursting or deforming. We manufacture hoses that handle specified pressure ratings, ensuring safe, reliable fluid transfer under demanding conditions, protecting equipment and operators from potential hazards and system failures.

- Flexibility: Hoses need to bend and adapt to complex system layouts. We design flexible hoses that maintain shape and performance while allowing easy installation, reducing stress on fittings, and enabling smooth routing even in confined or mobile hydraulic systems.

- Durability: Hoses face wear from abrasion, weather, and chemical exposure. We select premium rubber and reinforcement materials to ensure long-lasting performance, resist external damage, and maintain reliable operation in harsh industrial, agricultural, and automotive environments.

- Compatibility: Hydraulic hoses must connect seamlessly with system components. We provide hoses with various end fittings, couplings, and diameters to ensure leak-free connections, system efficiency, and safe, reliable operation across different hydraulic applications.

- Maintenance and Safety: Properly designed hoses reduce the risk of leaks and failures. We emphasize quality control and adherence to standards to enhance system safety, minimize downtime, and ensure consistent performance in demanding hydraulic operations.

Conclusion

Understanding hydraulic systems is crucial for anyone working with machinery or industrial equipment. Proper knowledge ensures safe operation, efficient energy transfer, and extended equipment life. By mastering the basics of components, pressure management, and maintenance practices, you can optimize system performance and reduce costly downtime.

Hydraulic systems are versatile and widely used in automotive, construction, manufacturing, and agricultural applications. Learning how each component interacts and how to troubleshoot common issues is essential. This knowledge allows operators to maintain smooth operations, improve safety, and maximize productivity across various industrial and commercial environments.

For reliable hydraulic solutions, get your wholesale hydraulic hoses from Kingdaflex. We offer durable, high-quality hoses designed for optimal performance, safety, and longevity in all hydraulic applications. Partner with Kingdaflex to ensure efficient fluid transfer and dependable operation for your systems.