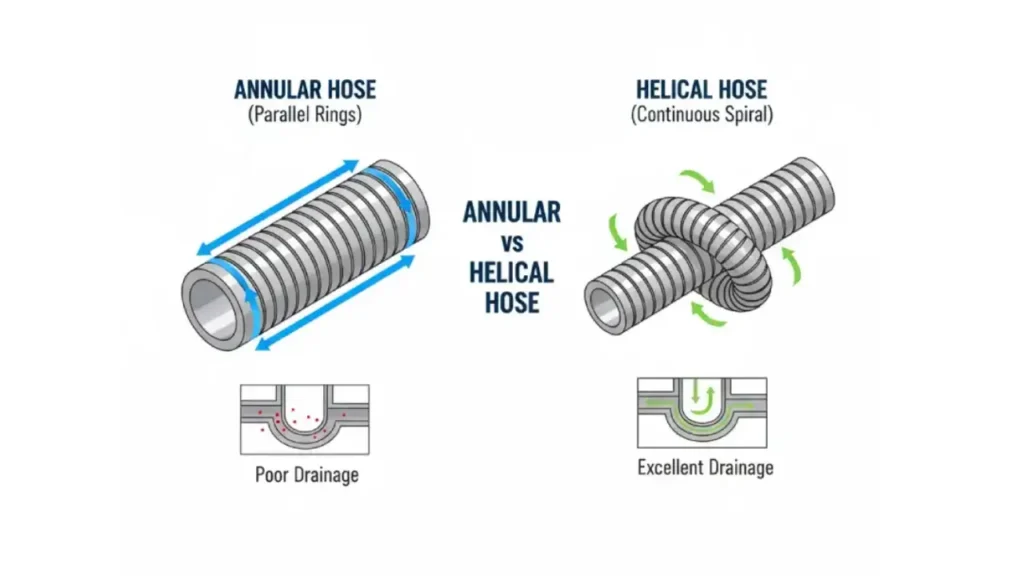

Corrugated metal hoses are essential for handling fluids under pressure and temperature extremes, but not all are created equal. When specifying a flexible metal line, the internal design—annular versus helical—is the most critical factor influencing performance. Understanding these structural differences is key to choosing the correct hose for vibration, high-pressure, or drainage applications.

Choosing between an annular and a helical hose depends entirely on your system’s demands. Each corrugated profile offers distinct trade-offs in flexibility, flow rate, and strength. We’ll break down the precise manufacturing and performance characteristics of both designs to help you determine which metal hose structure provides the best solution for your project.

What is an Annular Hose?

An annular hose is a type of flexible metal hose characterized by its distinctive corrugated pattern. The corrugations are a series of parallel, uniformly spaced rings that are perpendicular to the hose’s central axis. This structure is key to its flexibility and pressure rating, making it a common choice across many industrial applications.

- Structure and Corrugations: The hose features deep corrugations formed into parallel, circumferential rings, which resemble a succession of donuts stacked tightly together. This perpendicular pattern allows the hose to bend easily while maintaining a round cross-section, offering good flexibility in lateral motion.

- Manufacturing Process: Annular hoses are typically manufactured by hydraulically or mechanically forming the corrugations into a seamless or longitudinally welded metal tube. This process ensures the hose material remains consistent and free from helical welds that could introduce stress points, often leading to better pressure containment.

- Flexibility Characteristics: Due to the uniform ring structure, annular hoses offer a high degree of lateral flexibility, allowing them to handle movement in a side-to-side or offset manner effectively. However, they generally exhibit lower torsional (twisting) flexibility compared to their helical counterparts.

- Flow and Drainage: The parallel corrugations can potentially create pockets where fluid might collect, making complete self-drainage challenging, particularly when installed horizontally. This makes them less ideal for applications involving viscous fluids or processes requiring total purge of the media.

What is a Helical Hose?

A helical hose is a type of flexible metal hose distinguished by its continuous, screw-thread-like corrugated pattern. Unlike the ring-like annular design, the corrugations spiral around the hose’s central axis from one end to the other. This unique structure provides distinct performance advantages, particularly in drainage and torsional flexibility.

- Structure and Corrugations: The hose features a single, continuous corrugation that winds in a helix (or spiral) along the hose body, running at an angle to the axis. This uninterrupted path eliminates pockets, promoting superior self-draining properties for all fluids, including those that are viscous.

- Manufacturing Process: Helical hoses are often manufactured from a coiled metal strip that is formed and welded to create the continuous spiral structure. This process results in a very robust construction that is inherently strong against kinking and offers excellent resistance to twisting or torsional stresses.

- Flexibility Characteristics: The helical design provides superior torsional flexibility, meaning it can withstand twisting or rotation better than an annular hose. While still flexible, its lateral (side-to-side) flexibility is generally lower, making it ideal for routing where minimal lateral movement is expected.

- Flow and Drainage: The smooth, continuous spiral pathway acts like a channel, preventing fluid buildup within the corrugations. This is its key advantage, making helical hoses the preferred choice for processes where complete drainage and purging of the transferred medium are absolutely essential.

Annular vs Helical Hose

Selecting the correct corrugated metal hose is critical for system performance. The primary design difference lies in the corrugation pattern: annular (parallel rings) or helical (continuous spiral). Understanding how this structure affects key performance aspects is essential for proper fluid transfer.

Flexibility and Movement

Annular hoses feature corrugations perpendicular to the hose axis, offering superior lateral (side-to-side) flexibility. This makes them excellent for applications with offset motion, vibration, or thermal expansion requiring large-radius bends. However, they are less resistant to twisting.

Helical hoses, with their continuous spiral pattern, provide much better torsional (twisting) flexibility. They are highly resistant to kinking and torque, making them ideal for systems where the hose might be rotated during connection or operation, but their ability to handle large lateral offsets is limited.

Flow Dynamics and Drainage

The parallel rings of an annular hose create numerous small pockets where residual fluid can accumulate. This can be problematic when conveying viscous media or in applications requiring complete product purging to prevent contamination or bacterial growth.

A helical hose’s continuous spiral creates a natural channel that promotes excellent self-draining capability. This smooth, uninterrupted pathway is preferred for chemical, food-grade, or pharmaceutical applications where complete media evacuation and easy cleaning are paramount.

Pressure Resistance

Annular hoses generally have higher pressure ratings than comparable helical designs. Their parallel ring structure provides even distribution of internal stress, making them highly effective at resisting high burst pressure in static or less dynamic applications.

While strong, the continuous weld seam inherent in some helical manufacturing processes can sometimes limit their ultimate high-pressure capacity compared to the seamless formation of many annular designs. Their strength lies more in resisting the combined stress of pressure and movement.

Ease of Cleaning

Due to the internal pockets created by the perpendicular corrugations, cleaning annular hoses thoroughly can be more time-consuming and difficult, often requiring higher flow rates or specialized procedures for effective sanitation and removal of residues.

Helical hoses are significantly easier to clean. Their continuous spiral inner surface is highly efficient in allowing cleaning solutions (CIP/SIP—Clean-in-Place/Sterilize-in-Place) to flow without obstruction, which drastically reduces cleaning time and validates cleanliness standards.

Kink and Crush Resistance

The parallel ring design of the annular hose makes it more susceptible to kinking or deformation when bent past its minimum bend radius. A severe kink can permanently damage the corrugation, compromising the hose’s pressure integrity.

Helical hoses, especially those with deeper profiles, offer inherently superior kink and crush resistance. The spiral structure acts like a spring, distributing external loads and making the hose more resilient against accidental damage or excessive bending during installation or use.

Here are some differences between annular and helical hoses:

| Aspect | Annular Hose | Helical Hose |

| Corrugation Pattern | Continuous spiral (at an angle to the axis) | Continuous spiral (at an angle to axis) |

| Primary Flexibility | Superior Lateral (bending/offset) | Superior Torsional (twisting/rotation) |

| Drainage Capability | Poor (Pockets can trap fluid/residue) | Excellent (Self-draining channel) |

| Pressure Rating | Generally Higher (Even stress distribution) | Moderate (Limited by continuous weld seam) |

| Kink Resistance | Lower (Susceptible to damage upon over-bending) | Higher (Spiral structure resists deformation) |

How to Choose Annular and Helical Hoses?

Choosing between annular and helical metal hoses requires a careful assessment of your application’s specific needs. The decision hinges on which hose structure best addresses the fluid characteristics, system movements, and operational requirements you face. A mismatch can lead to premature failure or inefficient system performance.

- Analyze Movement Type: Select annular hoses if your system involves high lateral movement, offset parallel motion, or significant thermal expansion that requires flexibility in bending radius. Choose helical hoses if your primary concern is high-frequency vibration or torsional stress (twisting) during connection or use.

- Evaluate Drainage Requirements: Opt for helical hoses when dealing with viscous fluids, chemicals, or processes like food and pharmaceuticals that demand complete, self-draining purge capabilities. The continuous spiral channel prevents media accumulation, which annular hoses, with their ring pockets, cannot guarantee.

- Determine Pressure and Installation: For very high, static pressure systems, the even stress distribution of annular hoses often provides a slight advantage in burst strength. However, for applications involving rotation or high risk of kinking during complex installation, the inherent structure of the helical hose offers greater resilience.

- Consider Cleaning Procedures: If your system requires rigorous Clean-in-Place (CIP) or Sterilize-in-Place (SIP) protocols, the smooth internal path of a helical hose is easier and faster to sanitize. Annular corrugations can trap residue, demanding more intensive and time-consuming cleaning methods.

Conclusion

The choice between annular and helical metal hoses boils down to prioritizing either maximum flexibility (annular) or optimized drainage (helical) for your specialized application. Annular hoses excel in handling high lateral movement and lower pressure, while helical designs provide better self-draining capabilities and greater resistance to kinking and torque, crucial for specific industrial processes.

By grasping the fundamental differences in corrugation, you can minimize premature hose failure, reduce downtime, and ensure the long-term integrity of your fluid conveyance system. Proper selection translates directly to enhanced safety and operational efficiency, validating the need for a detailed technical evaluation before finalizing your procurement decision.

For all your high-performance fluid transfer needs, trust Kingdaflex to be your source. We manufacture a comprehensive range of quality metal hoses, along with a full line of wholesale hydraulic hoses, including popular SAE 100R grades. Contact Kingdaflex today for customized solutions and competitive pricing on hoses engineered for peak industrial reliability.