You start your hydraulic machine. Suddenly, the pump makes a loud noise. It sounds like gravel is inside the system. You look at the black rubber hose connected to the pump inlet. It looks flat or twisted.

This is a very bad sign. It is not a pump problem. It is a hose problem. This phenomenon is called “hose collapse.” If you do not fix it, it will destroy your hydraulic pump. In this article, we explain why this happens. We also explain how the SAE 100R4 hydraulic hose solves this problem.

Why Ordinary Hydraulic Hoses Collapse Under Vacuum

Most standard hydraulic hoses are engineered primarily to withstand positive internal pressure, not negative pressure. In typical hydraulic systems, fluid is pushed through the hose, causing the inner tube to expand outward while the reinforcement layer resists bursting. However, under vacuum or suction conditions, the stress direction is reversed.

When a hose is exposed to vacuum, the internal pressure drops below atmospheric pressure. External air pressure then compresses the hose wall inward. Ordinary pressure-rated hydraulic hoses lack sufficient radial stiffness, making them vulnerable to deformation or collapse.

Another contributing factor is hose construction. Many standard hydraulic hoses use braided wire reinforcement, which provides excellent tensile strength but limited resistance to inward compression. Without structural support to counteract external pressure, the hose can flatten, kink, or fully collapse.

Collapse is more likely to occur during:

- High-flow suction applications

- Long hose runs

- Elevated temperatures that soften rubber compounds

- Improper routing or excessive bending

Once collapse occurs, flow restriction increases sharply, leading to cavitation, pump damage, and system failure. This is why ordinary hydraulic hoses are unsuitable for vacuum and suction service.

How Helix Steel Wire Prevents Suction Hose Collapse

The defining feature of a true suction hose is the helix steel wire embedded in the hose wall. Unlike braided reinforcement, the helix wire acts as a structural skeleton, providing continuous radial support along the entire hose length.

Under vacuum conditions, external atmospheric pressure attempts to compress the hose inward. The helix wire resists this force by maintaining the hose’s circular shape, preventing flattening or collapse even under high vacuum levels.

Key benefits of helix wire reinforcement include:

- High resistance to vacuum-induced deformation

- Improved dimensional stability during suction cycles

- Ability to handle long hose lengths without collapse

- Better performance in elevated temperature environments

PVC vs SAE 100R4 Suction Hoses: Why Rubber Performs Better

PVC suction hoses are often chosen for their low cost and visual transparency. However, when compared to SAE 100R4 rubber suction hoses, PVC shows significant performance limitations in industrial environments.

PVC hoses tend to harden in cold temperatures and soften excessively under heat. This temperature sensitivity increases the risk of cracking, kinking, or collapse under vacuum. Additionally, PVC has limited chemical resistance to oils and petroleum-based fluids commonly used in hydraulic systems.

SAE 100R4 rubber hoses, typically made with oil-resistant synthetic rubber, offer superior performance:

- Stable flexibility across a wide temperature range

- Excellent compatibility with hydraulic oils and fuels

- Higher vacuum resistance due to reinforced construction

- Longer service life under continuous duty cycles

While PVC hoses may be suitable for light-duty water suction, they are not designed for demanding hydraulic suction or return applications. For industrial systems where reliability and safety matter, SAE 100R4 rubber hoses are the preferred solution.

SAE 100R4 Vacuum Rating Explained (SAE J517 Standard)

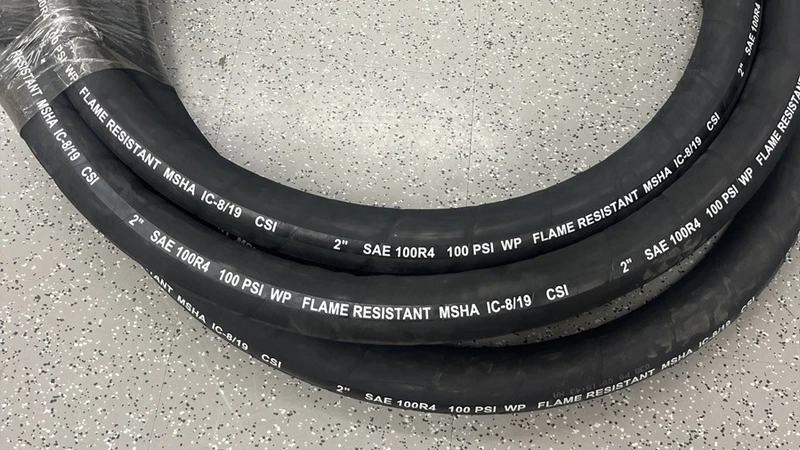

SAE 100R4 is defined under the SAE J517 standard, which specifies construction, performance, and testing requirements for hydraulic hoses. Unlike pressure hoses, SAE 100R4 focuses on suction and return service, including vacuum capability.

A key requirement of SAE 100R4 hoses is the ability to withstand full vacuum conditions without collapse. While the standard does not express vacuum rating in PSI, SAE 100R4 hoses are typically designed to handle vacuum levels approaching -0.08 to -0.095 MPa, depending on hose size and construction.

Compliance with SAE J517 ensures the hose can maintain structural integrity during suction, preventing flow restriction and system damage. When sourcing suction hoses, verifying SAE 100R4 compliance is critical for safe and reliable operation.

Suction and Return Applications for SAE 100R4 Hoses

SAE 100R4 hoses are specifically designed for hydraulic systems where fluid is drawn into the system or returned to the reservoir under low pressure. In suction applications, these hoses are commonly installed between the hydraulic pump inlet and the fluid tank, where maintaining an unrestricted flow path is critical. The helix wire reinforcement allows the hose to resist external atmospheric pressure, ensuring that the hose retains its round cross-section even under continuous vacuum conditions. This prevents flow starvation, reduces the risk of cavitation, and helps protect pumps and system components from premature wear.

In return line applications, SAE 100R4 hoses provide reliable performance for conveying hydraulic fluid back to the reservoir after it has passed through the system. Although return lines operate at relatively low pressure, they often experience high flow rates and elevated fluid temperatures. The oil-resistant rubber tube and reinforced construction of SAE 100R4 hoses allow them to handle these conditions without excessive expansion, deformation, or material degradation. This dual capability makes SAE 100R4 hoses a practical and versatile solution for both suction and return circuits in industrial and mobile hydraulic equipment.

How to Install SAE 100R4 Suction Hoses Correctly

Correct installation plays a decisive role in the performance and service life of SAE 100R4 suction hoses. During installation, the hose should be routed in a way that allows for smooth, gradual bends while respecting the minimum bend radius specified by the manufacturer. Sharp bends or forced alignment near fittings can create localized stress points, which may lead to reduced vacuum performance or early hose failure. Care should also be taken to avoid twisting the hose, as torsional stress can compromise the reinforcement structure over time.

Equally important is ensuring airtight connections throughout the suction line. Even small air leaks at fittings or clamps can introduce air into the system, leading to reduced pump efficiency and cavitation. Properly matched fittings, secure clamping, and clean sealing surfaces are essential for maintaining system integrity. When installed correctly, SAE 100R4 hoses deliver stable suction performance and long-term reliability in demanding hydraulic environments.

Proper Storage and Shelf Life for Rubber Suction Hoses

The performance of rubber suction hoses is strongly influenced by how they are stored prior to installation. Rubber compounds naturally age over time, and exposure to unfavorable conditions can accelerate this process. To preserve flexibility and material integrity, SAE 100R4 hoses should be stored in environments that are cool, dry, and protected from direct sunlight. Prolonged exposure to ultraviolet radiation, ozone, or excessive heat can cause the rubber to harden or crack, reducing its ability to withstand vacuum conditions.

When stored properly, rubber suction hoses typically maintain their serviceability for many years, often up to a decade depending on manufacturer guidelines. Hoses should be kept in a relaxed position, either laid straight or coiled with a large radius, to prevent permanent deformation. Before installation, a visual inspection is recommended to confirm that the hose remains free from surface damage or stiffness. Proper storage practices ensure that SAE 100R4 hoses perform as intended once they are placed into service.