Modern construction machinery, oil & gas systems, and mining equipment are increasingly designed to operate at higher hydraulic pressures in order to improve power density, efficiency, and system performance. As operating pressures continue to rise, traditional high-pressure hydraulic hoses are approaching their technical and safety limits, especially under demanding conditions such as high impulse cycles, extreme temperatures, and heavy mechanical stress.

This article provides a comprehensive overview of ultra-high-pressure hydraulic hose technology, covering key aspects such as materials, structural design, manufacturing challenges, performance standards, typical applications, and selection guidelines from a professional manufacturer’s perspective.

What Is an Ultra-High-Pressure Hydraulic Hose?

An Ultra-High-Pressure (UHP) hydraulic hose is designed to operate at working pressures typically equal to or exceeding 6,000 psi (400 bar). Common pressure ratings for UHP hoses include 6,000 psi, 10,000 psi, 15,000 psi, and up to 20,000 psi, depending on the hose structure, reinforcement layers, and application requirements. These hoses are engineered for systems where standard high-pressure hoses can no longer provide sufficient safety margins or service life.

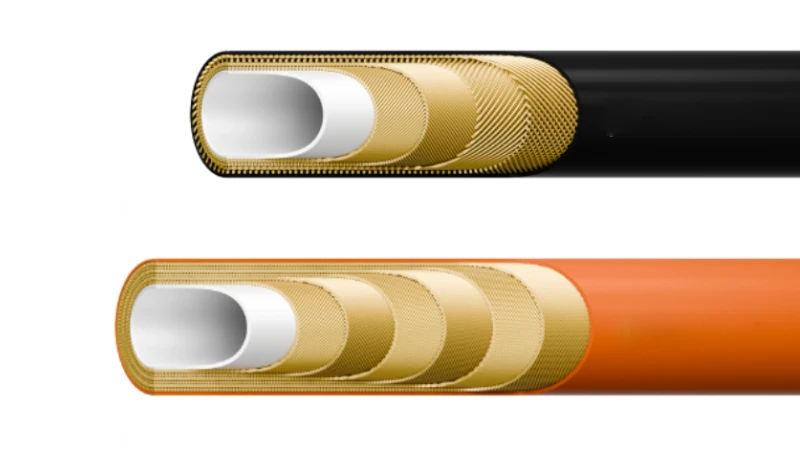

Compared to conventional high-pressure hydraulic hoses, UHP hoses feature multiple layers of high-tensile spiral steel wire reinforcement, thicker wall construction, and more advanced materials to withstand extreme internal pressure and impulse loads.

It is important to distinguish between working pressure and burst pressure. Working pressure represents the maximum continuous operating pressure, while burst pressure is the pressure at which hose failure occurs. UHP hydraulic hoses are designed with strict safety factors, ensuring reliable performance and enhanced safety in critical, high-risk applications.

Why Demand for Ultra-High-Pressure Hydraulic Hoses Is Increasing

Growth of Heavy Construction & Mining Equipment

Modern construction and mining equipment continues to evolve toward higher power density and greater productivity. Machines such as large excavators, drilling rigs, and mining loaders now operate under higher system pressures to deliver more force within limited space. This shift toward compact hydraulic system design places greater stress on hydraulic components, making ultra-high-pressure hydraulic hoses essential for maintaining performance, safety, and long service life under continuous heavy-duty operation.

Oil & Gas and Energy Applications

In the oil & gas and energy sectors, ultra-high-pressure hydraulic hoses are widely used for high-pressure injection systems, wellhead control, and offshore hydraulic equipment. These applications involve extreme operating conditions, including elevated temperatures, corrosive fluids, and severe pressure impulse cycles. Standard high-pressure hoses often struggle to meet these demands, driving the need for advanced UHP hose solutions.

Efficiency and System Downsizing

Operating at higher pressures allows hydraulic systems to use smaller hose diameters, reducing overall system weight and energy consumption. As a result, manufacturers must continuously upgrade materials, design methods, and production technologies to support this growing demand for ultra-high-pressure performance.

Key Materials Used in Ultra-High-Pressure Hydraulic Hose Technology

The performance and reliability of an ultra-high-pressure hydraulic hose depend heavily on the materials used in its construction. Each layer must be engineered to withstand extreme internal pressure, pressure impulses, and harsh operating environments while maintaining long-term stability.

Inner Tube Materials

The inner tube is responsible for fluid compatibility and pressure containment. Synthetic rubber compounds such as NBR and HNBR are commonly used due to their excellent resistance to petroleum-based hydraulic fluids and mechanical stress. For applications involving aggressive chemicals, elevated temperatures, or low permeability requirements, thermoplastic liners such as PTFE or polyamide (PA) are preferred. These materials offer superior chemical resistance, reduced fluid permeation, and consistent performance under sustained ultra-high pressure.

Reinforcement Layers

Reinforcement layers are the primary load-bearing structure of a UHP hydraulic hose. Multiple layers of spiral-wound steel wire reinforcement are used to evenly distribute internal pressure and improve fatigue resistance. Compared to standard steel wire, high-tensile or alloy steel wires provide higher strength and longer impulse life. As working pressure increases, the number of reinforcement layers must also increase, resulting in constructions such as 4SP, 6SP, or even 8SP, depending on the required pressure rating and safety factor.

Outer Cover Materials

The outer cover protects the hose from external damage and environmental exposure. Abrasion-resistant rubber compounds are widely used in construction and mining environments, while specialized covers can provide weather, ozone, and UV resistance. For high-risk applications, flame-resistant outer covers compliant with MSHA standards are available. Experienced manufacturers can customize cover formulations to match specific application and regulatory requirements.

Structural Design of Ultra-High-Pressure Hydraulic Hoses

The structural design of an ultra-high-pressure hydraulic hose is critical to its ability to withstand extreme operating conditions while maintaining reliability and service life. Unlike standard hydraulic hoses, UHP hoses require specialized reinforcement structures and precise dimensional control.

Spiral vs. Braided Reinforcement

For ultra-high-pressure applications, spiral reinforcement is essential. Braided reinforcement is suitable for medium to high pressures but lacks the fatigue resistance required for extreme pressure cycling. Spiral-wound steel wire layers distribute internal pressure more evenly along the hose structure, significantly improving impulse life and resistance to pressure spikes. This makes spiral construction the preferred choice for UHP hydraulic systems operating under continuous or fluctuating high loads.

Hose Diameter and Wall Thickness Optimization

Designing a UHP hydraulic hose involves balancing inner diameter, wall thickness, and pressure rating. Increasing wall thickness enhances pressure resistance but can reduce hose flexibility. Manufacturers must optimize these parameters to achieve the required working pressure while maintaining acceptable flow capacity and mechanical performance.

Bending Radius and Installation Considerations

Due to their reinforced structure, ultra-high-pressure hydraulic hoses have a larger minimum bending radius. Exceeding this limit or applying torsional stress during installation can lead to premature failure. Proper hose routing and adherence to installation guidelines are therefore critical for long-term performance and safety.

Manufacturing Challenges in Ultra-High-Pressure Hydraulic Hose Production

Manufacturing ultra-high-pressure hydraulic hoses involves a level of technical complexity that goes far beyond standard hose production. One of the most critical challenges is high-precision steel wire tension control during the spiral winding process. Even minor deviations in wire tension can result in uneven stress distribution, reduced pressure capacity, and shortened service life.

Maintaining consistency across multiple reinforcement layers is equally demanding, particularly for 6SP or 8SP ultra-high-pressure hose constructions. Each spiral layer must be precisely aligned to ensure uniform load sharing under extreme internal pressure. In addition, the vulcanization process and temperature control must be tightly regulated to achieve proper bonding between layers without compromising material properties or flexibility.

Advanced manufacturers also rely on in-line pressure testing and impulse testing to verify hose performance before delivery. At Kingdaflex, strict quality control systems, standardized testing procedures, and compliance with international standards are integral parts of the production process. These measures ensure that every ultra-high-pressure hydraulic hose meets demanding safety, reliability, and performance requirements for critical applications worldwide.

Typical Applications of Ultra-High-Pressure Hydraulic Hoses

Ultra-high-pressure hydraulic hoses are essential in applications where extreme operating pressure, high impulse cycles, and demanding environmental conditions exceed the capabilities of standard hydraulic hoses.

Construction and Mining Equipment

In construction and mining operations, ultra-high-pressure hydraulic hoses are widely used on excavators, drilling rigs, and rock breakers. These machines rely on high system pressure to generate maximum force in confined spaces while operating under continuous heavy loads. UHP hoses provide the pressure stability and fatigue resistance required to withstand constant vibration, pressure spikes, and abrasive environments commonly found on job sites.

Oil & Gas Industry

Within the oil and gas sector, ultra-high-pressure hydraulic hoses are critical for hydraulic control lines and high-pressure injection systems. These applications demand exceptional resistance to pressure impulses, temperature extremes, and chemically aggressive fluids. Reliable UHP hose performance is essential for maintaining operational safety and preventing costly downtime in both onshore and offshore installations.

Industrial & Specialized Equipment

Ultra-high-pressure hydraulic hoses are also used in hydraulic presses, water jetting systems, and offshore equipment, where precise pressure control and long service life are required. In these specialized systems, consistent hose performance directly impacts productivity, equipment safety, and overall system reliability.

How to Select the Right Ultra-High-Pressure Hydraulic Hose

Selecting the correct ultra-high-pressure hydraulic hose is critical to system safety, reliability, and long-term performance. The first step is to clearly define the required working pressure, ensuring that the hose provides an adequate safety factor in accordance with applicable international standards. Pressure spikes and impulse cycles should always be considered, not just nominal system pressure.

The operating temperature range must also be evaluated, as extreme heat or cold can affect material properties and service life. Fluid compatibility is another key factor, since incompatible fluids can degrade the inner tube and compromise hose integrity over time.

Installation conditions should be carefully reviewed, particularly the minimum bending radius, to prevent excessive mechanical stress during operation. Compliance with relevant standards such as SAE, EN, or ISO specifications ensures consistent performance and interchangeability across systems.

Finally, custom hose lengths, end fittings, and assembly requirements should be addressed early in the selection process. Because ultra-high-pressure systems involve higher risk, working with an experienced hydraulic hose manufacturer is critical to achieving safe, reliable, and application-specific solutions.

Conclusion: The Role of Manufacturers in Advancing UHP Hose Technology

Ultra-high-pressure hydraulic hose technology has become increasingly important as hydraulic systems continue to evolve toward higher pressure, greater efficiency, and more compact designs. Meeting these demands requires advanced materials, optimized structural design, and precise manufacturing processes.

UHP Hose Manufacturers play a critical role in advancing UHP hose technology by investing in engineering expertise, strict quality control, and comprehensive testing capabilities. Reliable ultra-high-pressure performance cannot be achieved through materials or design alone—it depends on the manufacturer’s ability to consistently produce hoses that meet international standards under real-world operating conditions.

Manufacturers with advanced production and testing capabilities are better positioned to support high-pressure hydraulic systems, ensuring safety, durability, and long-term performance across demanding global applications.