Peristaltic pumps are indispensable tools in various industries, known for their reliability and precision. These pumps operate by squeezing a flexible hose or tube to create a flow of liquid. However, like any mechanical equipment, peristaltic pumps are not immune to issues, and one common problem is hose failure.

In this article, we will delve into the causes of peristaltic pump hose failure, how to prevent it, and solutions to address this issue.

What Is Peristaltic Pump Hose?

A peristaltic pump hose is a crucial component of a peristaltic pump system. It is a flexible tube or hose that is used to transport fluids from one place to another within the peristaltic pump. This type of pump operates by squeezing and releasing this flexible hose or tube in a rhythmic, rolling motion, creating a pulsating flow of liquid.

The hose in a peristaltic pump is designed to be highly flexible and resilient, allowing it to withstand the repeated squeezing and releasing action of the pump’s rollers or shoes without breaking or deforming. It plays a vital role in maintaining the integrity of the fluid being transferred, ensuring that it remains uncontaminated and properly controlled.

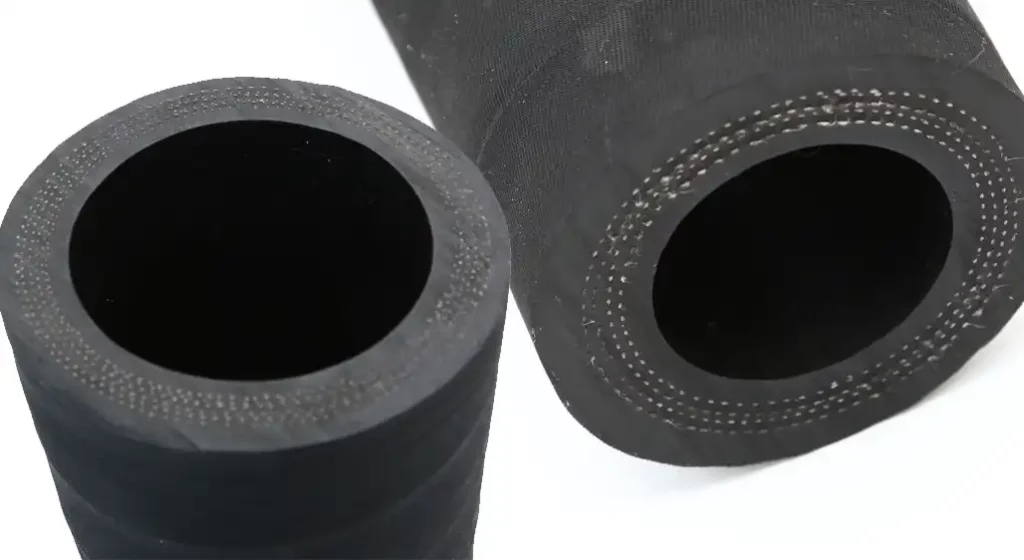

The material of the peristaltic pump hose is selected based on the type of fluid being pumped and the specific application. Common materials for these hoses include silicone, rubber, and thermoplastic elastomers, each with its own set of properties suited to different environments and fluids.

A peristaltic pump hose is a flexible tubing used in peristaltic pump systems to facilitate the controlled movement and transfer of fluids, making it a fundamental part of the pump’s operation.

Causes of Peristaltic Pump Hose Failure

Abrasion

Abrasion is a primary cause of hose failure. Continuous friction between the hose and rollers can lead to wear and tear, eventually causing leaks or ruptures.

Chemical Incompatibility

Using the wrong hose material for the type of fluid being pumped can result in chemical degradation, leading to hose failure.

Overloading

Overloading the pump or exceeding its pressure and flow limits can strain the hose, causing it to fail prematurely.

Temperature Extremes

Extreme temperatures, whether hot or cold, can affect the flexibility and resilience of the hose, making it more susceptible to failure.

Poor Maintenance

Neglecting regular maintenance, such as inspecting and replacing hoses as needed, can lead to unexpected failures.

Prevention Measures

Proper Hose Selection

Select hoses that are compatible with the pumped fluid and designed for the operating conditions.

Regular Inspection

Frequent inspection of hoses for signs of wear, abrasion, or chemical damage is crucial. Replace hoses at the first sign of deterioration.

Monitoring Pressure and Flow

Ensure that the pump operates within its specified pressure and flow limits to prevent overloading and premature hose failure.

Temperature Control

Maintain suitable temperature conditions to prevent damage caused by extreme heat or cold.

Routine Maintenance

Implement a regular maintenance schedule, including hose replacements and lubrication of moving parts.

Solutions for Peristaltic Pump Hose Failure

Immediate Replacement

If a hose fails, it should be replaced promptly to avoid contamination and further damage.

Hose Reinforcement

Consider using reinforced hoses or protective sleeves to enhance hose durability in abrasive environments.

Upgrading Pump Components

Upgrading rollers or shoes to materials with better wear resistance can prolong hose life.

Training and Education

Ensure that personnel operating the peristaltic pump are adequately trained to prevent operational errors leading to hose failure.

Redundancy

Implement redundancy by having spare hoses and pumps on hand to minimize downtime in case of failure.

Conclusion

Peristaltic pump hose failure can be costly and disruptive, but with proper preventive measures and swift solutions, its impact can be mitigated. Regular maintenance, suitable hose selection, and operator training are key to ensuring the longevity and reliability of peristaltic pumps in various industries.

FAQs

Is hose failure common in peristaltic pumps?

Hose failure can occur, but with proper maintenance and care, it can be minimized.

What materials are suitable for peristaltic pump hoses?

The choice of hose material depends on the pumped fluid. Common materials include silicone, rubber, and thermoplastic elastomers.

How can I prevent hose abrasion in peristaltic pumps?

Using reinforced hoses and monitoring for wear regularly can help prevent abrasion-related failures.

Are there any warning signs of hose failure?

Yes, warning signs include visible wear, leaks, and changes in pump performance.

Can I repair a damaged peristaltic pump hose?

In most cases, it is best to replace a damaged hose rather than attempting repairs to maintain reliability.