Ferrule fittings are an essential component in various industries where fluid or gas transportation and containment are of utmost importance. These fittings are known for their reliability, ease of installation, and ability to create leak-tight seals in demanding environments.

This article will delve into ferrule fittings, exploring their types, working principles, advantages, applications, installation procedures, maintenance, troubleshooting, and more.

What is a Ferrule Fitting?

Ferrule fittings are sometimes referred to as compression fittings, and they can play a pivotal role in fluid and gas systems.

They are widely used in petrochemicals, pharmaceuticals, food processing, and instrumentation industries. These fittings are designed to connect and seal tubing or pipes efficiently, ensuring there is no leakage.

Quote Your Desired Ferrule Fittings Now

What Do Ferrule Fittings Consist of?

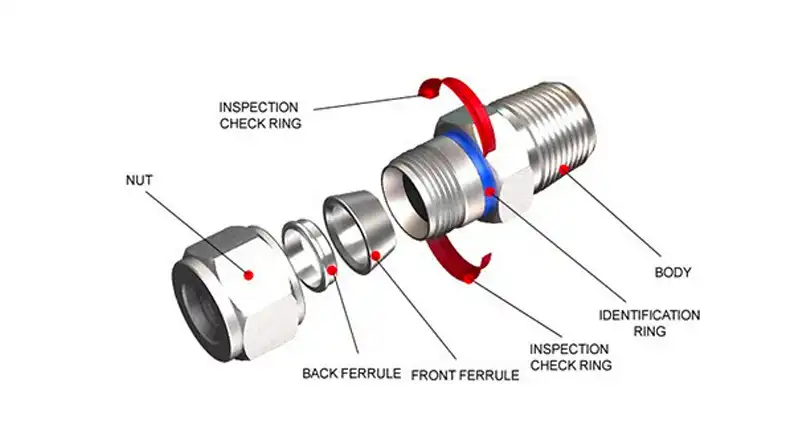

Ferrule fittings consist of two primary components: a nut and a ferrule. These two components work together to create a secure and leak-tight connection in various fluid and gas systems.

Here’s a closer look at each component:

Nut:

The nut is typically made of stainless steel, known for its durability and corrosion resistance. It plays a crucial role in the assembly of the ferrule fitting. When tightened, the nut applies pressure on the ferrule, compressing it tightly against the tubing or pipe. This compression is what ensures the seal, preventing any fluid or gas from escaping. The nut’s design and quality are essential for maintaining the integrity of the connection over time.

Ferrule:

The ferrule, usually made of a softer material like brass or plastic, is the sealing component of the ferrule fitting. There are two types of ferrules, a front ferrule, and a back ferrule, in the case of double ferrule fittings. When the nut is tightened, it compresses the ferrule(s) against the tubing or pipe, causing the ferrule to deform and grip the surface tightly. This deformation creates a secure and reliable seal that is highly resistant to leaks. The choice of ferrule material is significant, as it affects the fitting’s performance and compatibility with the intended application.

The nut and ferrule are the key elements of ferrule fittings, working in tandem to provide a dependable, leak-free connection in fluid and gas systems. The nut provides the mechanical force necessary for compression, while the ferrule forms the seal that ensures the integrity of the system.

These components are selected based on the specific requirements of the application, considering factors like material compatibility, pressure, and temperature conditions.

Types of Ferrule Fittings

Ferrule fittings come in two main types: single ferrule fittings and double ferrule fittings.

Single Ferrule Fittings

Single ferrule fittings utilize a single ferrule to create a seal between the tubing and the fitting body. These fittings are relatively easier to install and are commonly used in applications where regular disconnection and reassembly are not required.

Double Ferrule Fittings

Double ferrule fittings, on the other hand, use two ferrules: the front and back ferrules. The double ferrule design enhances reliability and ensures a consistent, leak-free connection. These fittings are more suitable for applications that demand frequent assembly and disassembly.

Quote Your Desired Ferrule Fittings Now

How Do Ferrule Fittings Work?

Ferrule fittings work on a simple yet effective principle to create secure and leak-tight connections in fluid and gas systems.

Here’s how they work:

- Compression Sealing: Ferrule fittings, also known as compression fittings, utilize the concept of compression sealing. They consist of a nut and one or two ferrules (depending on whether they are single or double ferrule fittings). The ferrules are typically made of a softer material like brass or plastic.

- Tightening the Nut: To create a seal, you start by assembling the fitting components, which include the nut and the ferrule(s), onto the tubing or pipe. The nut, often made of stainless steel for its strength and corrosion resistance, is threaded onto the fitting body.

- Ferrule Deformation: As you tighten the nut, it exerts force on the ferrule(s), causing them to deform or “bite” into the surface of the tubing or pipe. This deformation is crucial for creating a secure, leak-free seal.

- Leak Prevention: The compression of the ferrule(s) around the tubing or pipe effectively seals the connection. It prevents any fluid or gas from escaping, even under high pressure. This mechanism ensures that the system remains leak-tight and operates without any loss of the contained substance.

- Reusability: One of the advantages of ferrule fittings is their reusability. They can be disconnected and reassembled without compromising the sealing integrity, making them suitable for applications that require frequent assembly and disassembly.

Ferrule fittings work by using the mechanical force applied by the nut to deform the ferrule(s) and create a tight grip around the tubing or pipe. This compression sealing method ensures a reliable and leak-free connection, making ferrule fittings a preferred choice in various industries where maintaining the integrity of fluid and gas systems is critical.

Advantages of Ferrule Fittings

Ferrule fittings offer several advantages, making them a preferred choice in many industries.

- Reliability: These fittings create a secure and leak-free connection, ensuring the integrity of fluid and gas systems.

- Easy Installation: Ferrule fittings are relatively easy to install, reducing downtime during maintenance or system setup.

- Versatility: They can be used in various applications, from high-pressure systems to those requiring frequent disassembly.

- Corrosion Resistance: Stainless steel nuts provide excellent resistance to corrosion.

- Longevity: Ferrule fittings have a long service life, reducing the need for frequent replacements.

Common Applications of Ferrule Fittings

Ferrule fittings find applications in various industries, including:

- Petrochemical

- Pharmaceutical

- Food and beverage

- Laboratory and instrumentation

- HVAC (Heating, Ventilation, and Air Conditioning)

Installation of Ferrule Fittings

Proper installation is crucial to ensure the effectiveness of ferrule fittings. Here’s a step-by-step guide:

Step 1: Measuring and Cutting

Measure the tubing or pipe accurately and cut it to the desired length.

Step 2: Deburring

Remove any burrs or sharp edges from the cut end to prevent damage to the ferrule.

Step 3: Fitting Assembly

Assemble the fitting components, including the ferrule, nut, and tubing. Tighten the nut to create a secure seal.

Proper Maintenance of Ferrule Fittings

Regular maintenance is essential to prolong the life of ferrule fittings. Inspect for wear, corrosion, or damage, and replace any components as needed. Lubricating the threads can also aid in installation and disassembly.

Troubleshooting Ferrule Fitting Issues

Common issues with ferrule fittings include leakage and improper sealing. Troubleshooting involves checking for loose nuts, damaged ferrules, or tubing misalignment. Proper assembly and tightening are key to preventing these problems.

Comparing Ferrule Fittings to Other Connection Methods

Ferrule fittings are often compared to other connection methods, such as threaded connections, welded joints, and flanged connections. The advantages of ferrule fittings, such as ease of installation and reusability, make them a favorable choice in many applications.

Importance of Quality in Ferrule Fittings

The quality of ferrule fittings is paramount. Choosing high-quality materials and components ensures the integrity of the system, reduces the risk of leaks, and enhances overall safety.

Choosing the Right Ferrule Fitting for Your Needs

Selecting the right ferrule fitting depends on factors like the type of fluid or gas, pressure, temperature, and the specific requirements of your application. Consult with experts to make an informed choice.

Conclusion

Ferrule fittings are indispensable in various industries, ensuring leak-tight connections and the smooth operation of fluid and gas systems. Their ease of installation, reliability, and versatility make them a preferred choice. Proper installation, maintenance, and material selection are key to maximizing their benefits.

Quote Your Desired Ferrule Fittings Now

Frequently Asked Questions (FAQs)

What are ferrule fittings used for?

Ferrule fittings are used to connect and seal tubing or pipes in various industries to prevent leaks in fluid and gas systems.

How do ferrule fittings create a seal?

Ferrule fittings create a seal by compressing a soft ferrule around the tubing when the nut is tightened, preventing leakage.

What are the main types of ferrule fittings?

There are two main types of ferrule fittings: single ferrule fittings and double ferrule fittings.

Are ferrule fittings easy to install?

Yes, ferrule fittings are relatively easy to install, reducing downtime during maintenance or system setup.

How do I choose the right ferrule fitting for my application?

The choice depends on factors like the type of fluid or gas, pressure, temperature, and specific requirements. Consult experts for guidance.