Upgrade your hydraulic system’s safety and performance with non-conductive hose fittings. Eliminate electrical hazards, improve reliability, and maximize uptime. Shop our selection of high-quality fittings today!

No more excess hose! We offer custom lengths for your specific application, reducing wasted material and ensuring a clean, efficient setup.

From high-temperature thermoplastics to abrasion-resistant composites, we offer various non-conductive materials to suit your specific operating environment and pressure requirements.

Need a specific thread pattern, port size, or angle? We provide a wide range of non-conductive fittings to match your existing equipment and create the perfect connection.

Our technicians ensure secure and leak-proof connections with every custom hose assembly. We guarantee a professional finish that meets the highest safety standards.

Tame the power, not the current. Non-conductive hydraulic hoses eliminate electrical hazards, boosting safety and reliability. Get a custom quote for your exact needs – length, hydraulic hose fittings, material – for a system that performs flawlessly.

Non-conductive hydraulic hose fittings are essential components in applications where electrical safety and performance are paramount. Here are some key applications that benefit from their use:

In applications near power lines, electrical equipment, or where there’s a risk of stray current, non-conductive hoses and fittings prevent accidental arcing or shock hazards. This is crucial for industries like construction, mining, and utilities.

When working with delicate electronic equipment, non-conductive hoses protect them from stray electrical currents that could damage components. This is important in data centers, medical facilities, and manufacturing clean rooms.

Modern agricultural equipment often utilizes hydraulic systems, and non-conductive hoses ensure operator safety when working around power lines or in wet conditions.

In environments with flammable materials or gases, such as chemical plants, refineries, and paint booths, non-conductive hoses eliminate the risk of sparks igniting a fire or explosion.

To maintain hygiene and prevent contamination, non-conductive hoses are used in food and beverage processing equipment where electrical components are present near washdown areas.

Non-conductive hoses find applications in various transportation vehicles, including construction equipment, forklifts, and aerial lifts, to enhance safety and prevent electrical issues.

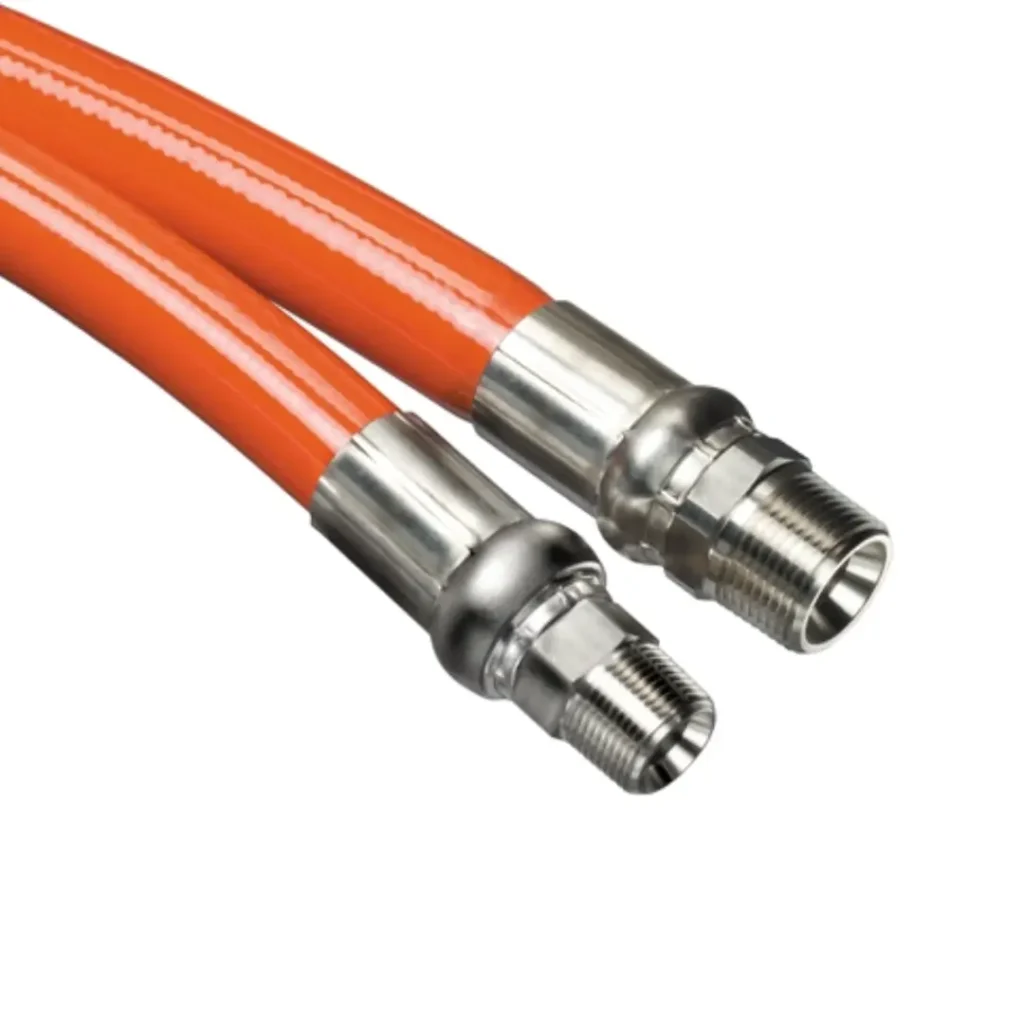

Non-conductive hydraulic hose fittings are specialized components designed to connect hydraulic hoses while preventing the flow of electricity.

Unlike standard hydraulic fittings often made from conductive materials like steel, non-conductive fittings are crafted from materials like nylon, synthetics, or composites. This makes them ideal for applications where electrical safety is paramount.

Here’s a breakdown of what they are and why they’re important:

In essence, non-conductive hydraulic hose fittings are essential for ensuring a safe and reliable hydraulic system operation in situations where electrical safety is a top priority.

Non-conductive hydraulic hose fittings are crucial for applications where electrical safety is a primary concern. Standard hydraulic hoses are typically made of materials like steel or rubber, which can conduct electricity. In environments with a risk of stray current, electrical equipment nearby, or flammable materials, this conductivity can lead to:

Non-conductive hoses and fittings, typically made from nylon, synthetics, or composites, prevent these risks by offering high electrical resistance, often exceeding 1000 volts.

Yes, non-conductive hydraulic hose fittings come in various types to match existing equipment and applications. Some common types include:

The choice of fitting type depends on factors like pressure requirements, reusability needs, and connection style of existing equipment.

There are several advantages to using non-conductive hydraulic hose fittings:

Choosing the right non-conductive hydraulic hose fitting requires considering several factors: