Choosing the correct air compressor hose size is essential for optimal performance and efficiency. The hose’s diameter directly impacts airflow, pressure, and the tools’ functionality. Incorrect sizing can lead to reduced power, increased wear, and even system malfunctions. Understanding the factors that determine the appropriate hose size is crucial for any air compressor setup.

This blog post will delve into the various considerations for selecting the right air compressor hose size. We’ll explore how hose diameter, length, and tool requirements influence airflow and pressure. By providing practical guidelines and insights, we aim to help you make informed decisions for your air compressor applications.

What is Air Compressor Hose

An air compressor hose is a flexible conduit designed to transport compressed air from an air compressor to various pneumatic tools and equipment. These hoses are essential for powering tools like air wrenches, nail guns, spray guns, and tire inflators. They are engineered to withstand the pressures generated by air compressors and deliver a consistent airflow to the connected tools.

Air compressor hoses are typically made from materials like rubber, PVC, polyurethane, or hybrid blends, each offering distinct advantages in terms of flexibility, durability, and resistance to abrasion, chemicals, and temperature variations. The selection of the appropriate hose material and size is crucial for ensuring efficient and safe operation, preventing pressure drops, and maximizing the performance of pneumatic tools.

Air Compressor Hose Sizes

Air compressor hose sizes are crucial for ensuring optimal performance of pneumatic tools and equipment. The hose’s inner diameter (ID) and length directly impact airflow and pressure delivery. Selecting the correct size prevents pressure drops, reduces tool inefficiency, and minimizes energy loss. Understanding the relationship between hose size, compressor output, and tool requirements is essential for efficient operation.

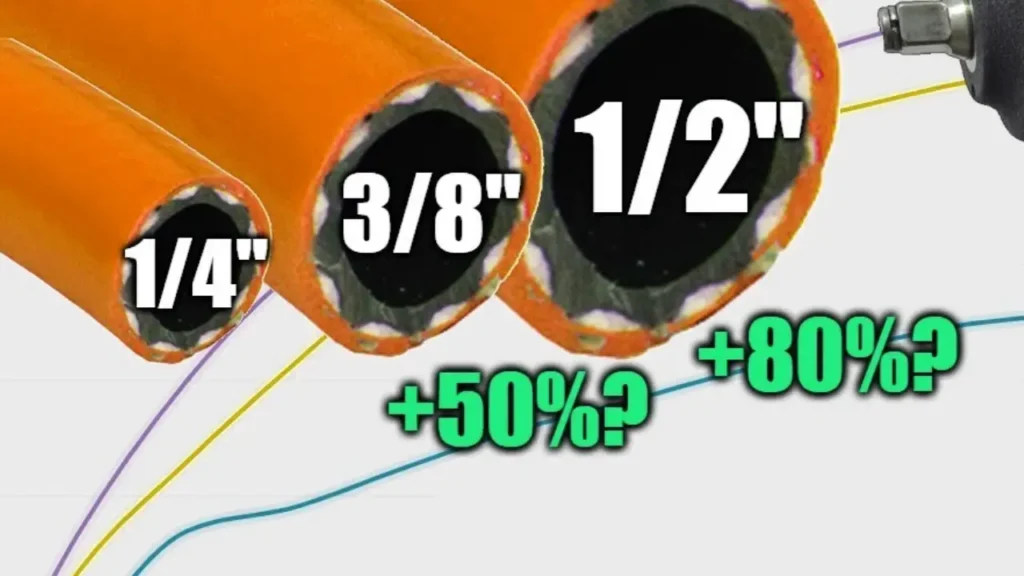

The inner diameter of an air compressor hose determines the volume of air that can flow through it. Smaller IDs restrict airflow, leading to pressure drops and reduced tool performance, especially over longer distances. Larger IDs allow for greater airflow, ensuring consistent pressure delivery to tools with high air consumption. The hose’s length also plays a significant role; longer hoses increase friction and pressure loss, necessitating larger IDs for effective operation.

Common air compressor hose sizes range from 1/4 inch to 1 inch ID, with lengths varying from 25 feet to 100 feet or more. The appropriate size depends on the specific application, the compressor’s output (CFM), and the tool’s air consumption. Matching these factors ensures optimal performance and prevents unnecessary strain on the compressor and tools.

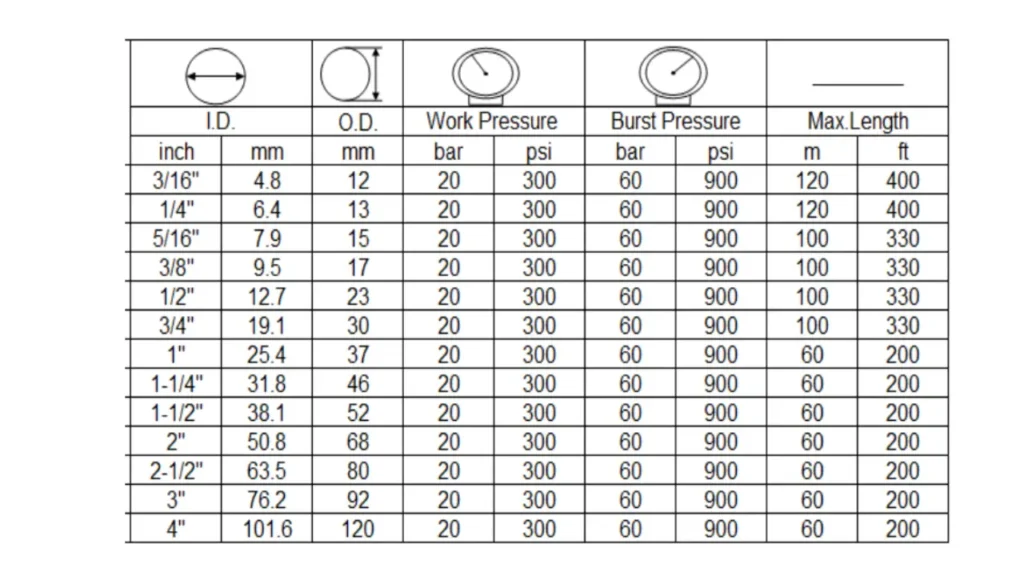

Air compressor hose size chart in the following:

| Hose Inner Diameter (ID) | Common Applications | Advantages | Disadvantages |

| 1/4 inch | Light-duty tools, tire inflation, small nail guns | Lightweight, flexible, suitable for low-CFM applications | Limited airflow, significant pressure drop over long distances |

| 3/8 inch | General-purpose tools, impact wrenches, spray guns | Versatile, good balance of airflow and flexibility | May experience pressure drops with high-CFM tools over long distances |

| 1/2 inch | Heavy-duty tools, large impact wrenches, sandblasting | High airflow capacity, minimal pressure drop over moderate distances | Less flexible, heavier, may be overkill for low-CFM tools |

| 3/4 inch and 1 inch | Industrial applications, high-volume air tools, large compressors | Maximum airflow, minimal pressure drop over long distances, suitable for high-demand applications | Bulky, heavy, less flexible, typically used in stationary industrial setups |

What Size Hose for Air Compressor

Selecting the right air compressor hose size is crucial for optimal performance and efficiency. The hose’s inner diameter (ID) and length directly impact airflow, pressure delivery, and tool functionality. Understanding these factors ensures you choose the appropriate hose for your specific application.

Understanding Inner Diameter (ID)

The inner diameter of an air compressor hose dictates the volume of air that can flow through it. A smaller ID restricts airflow, leading to pressure drops and reduced tool performance, especially over longer distances. Conversely, a larger ID allows for greater airflow, ensuring consistent pressure delivery to tools with high air consumption. The choice of ID depends on the compressor’s output (CFM) and the tool’s air consumption.

For light-duty applications, such as inflating tires or using small nail guns, a 1/4-inch ID hose is often sufficient. General-purpose tools, like impact wrenches and spray guns, typically require a 3/8-inch ID hose for optimal performance. Heavy-duty tools, such as large impact wrenches or sandblasters, demand a 1/2-inch ID hose or larger to ensure adequate airflow and pressure delivery.

Understanding Hose Length

The length of an air compressor hose also significantly affects airflow and pressure delivery. Longer hoses increase friction, resulting in pressure drops and reduced tool efficiency. To compensate for this, a larger ID hose is necessary for longer runs. The distance between the compressor and the tool should be considered when selecting hose length.

For shorter distances, a 25-foot hose may be sufficient, but for longer runs, such as 50 feet or more, a larger ID hose is recommended to minimize pressure loss. In industrial settings with extensive piping systems, 3/4-inch or 1-inch ID hoses might be required to ensure consistent pressure delivery over long distances. Matching the hose length to the application’s requirements ensures optimal performance and prevents unnecessary strain on the compressor and tools.

How to Measure Air Compressor Hose Size

Accurately measuring air compressor hose size is crucial for ensuring optimal performance and preventing pressure drops. The hose’s inner diameter (ID) and length directly impact airflow and pressure delivery. Here’s a step-by-step guide to measuring air compressor hose size.

Step 1. Measuring the Inner Diameter (ID)

The inner diameter (ID) of an air compressor hose is the most critical measurement, as it determines the volume of air that can flow through the hose. To measure the ID, use a caliper or ruler to measure the distance between the inside walls of the hose. If you’re measuring a used hose, ensure it’s clean and free of debris to get an accurate reading.

Accurate ID measurement is essential for proper air flow. Too small of an ID leads to pressure drop. Take precise measurements, and consider the application needs to ensure the correct size is chosen.

If you don’t have access to a caliper, you can also measure the outer diameter (OD) and subtract twice the wall thickness. However, this method requires accurate knowledge of the hose’s wall thickness, which may not always be readily available. It’s generally more reliable to measure the ID directly when possible.

Step 2. Measuring the Hose Length

The length of an air compressor hose is also crucial, as it affects pressure drop and tool performance. To measure the length, simply extend the hose fully and use a measuring tape or ruler to measure the distance from one end to the other. Ensure the hose is straight and not coiled or kinked during measurement to obtain an accurate reading.

Hose length directly impacts pressure delivery. Longer hoses create more friction, causing pressure drops. Measure the length accurately, and consider the application’s distance requirements to choose the correct hose length.

For coiled hoses, it’s best to uncoil them completely before measuring to ensure accuracy. If the hose is permanently installed, you may need to measure in sections or use a laser distance measure for longer distances. Always double-check your measurements to avoid errors.

How to Choose the Best Size Hose for Air Compressor

Selecting the optimal air compressor hose size is essential for maximizing tool performance and minimizing pressure drops. The hose’s inner diameter (ID) and length directly impact airflow, making it crucial to match these dimensions to the specific needs of your air compressor and pneumatic tools. Proper hose selection ensures efficient operation and prevents unnecessary strain on your equipment.

Here are key factors to consider when choosing the best size hose for your air compressor:

Tool Air Consumption (CFM):

Match the hose ID to the tool’s CFM requirements. High-CFM tools demand larger ID hoses to maintain adequate pressure. Using a smaller ID hose can result in significant pressure drops, reducing tool efficiency and performance. Consider the tool’s specifications to ensure the hose can deliver the necessary airflow.

Hose Length:

Account for the hose’s length, as longer hoses increase friction and pressure loss. Longer hoses require larger IDs to compensate for this loss. For extended distances, consider using a larger ID hose to maintain adequate pressure at the tool.

Application Requirements:

Consider the specific application and operating environment. Heavy-duty applications or those requiring high precision may necessitate larger ID hoses and shorter lengths. For light-duty tasks, a smaller ID hose may suffice. Evaluate the application’s demands to determine the most suitable hose size.

Compressor Output (CFM):

Ensure the hose ID is compatible with the compressor’s CFM output. Using a hose that restricts airflow can strain the compressor and reduce its efficiency. The hose should allow the compressor to deliver its rated CFM without excessive pressure drops.

Conclusion

In conclusion, selecting the correct air compressor hose size is vital for maximizing efficiency and preventing performance issues. Hose size directly impacts airflow, pressure, and tool operation, making it crucial to match the hose’s inner diameter and length to the compressor’s output and tool requirements. Understanding these factors ensures optimal system performance and longevity.

Using an undersized hose can lead to pressure drops and reduced tool performance, while an oversized hose may result in unnecessary bulk and cost. Proper hose selection minimizes energy loss and maximizes the effectiveness of pneumatic tools, enhancing overall productivity and operational efficiency.

For a wide range of high-quality air compressor hoses tailored to various applications, choose Kingdaflex. We offer wholesale options with diverse sizes and materials to meet your specific needs. Contact us today to explore our product offerings and ensure your air compressor systems operate at peak performance.