When it comes to upgrading your vehicle’s fluid lines, the choice of hose material is critical. Two popular options dominate the market: braided nylon and stainless steel. This guide will break down the key differences, helping you understand which material is the best fit for your specific automotive needs.

Choosing the right hose impacts performance, durability, and cost. While both braided nylon and stainless steel offer significant improvements over traditional rubber hoses, they each have distinct advantages and disadvantages in terms of weight, flexibility, and resistance to wear and tear.

What Is a Nylon Hose?

A nylon hose is a flexible tube made from nylon, a synthetic polymer known for its strength, durability, and resistance to chemicals and abrasion. These nylon hoses are commonly used in various applications due to their versatility and reliable performance. Nylon hoses can handle a range of pressures and temperatures, making them suitable for both industrial and domestic use. Their flexibility allows for easy routing and installation in tight spaces, and their lightweight nature simplifies handling and transport.

Nylon hoses find applications in pneumatic systems, fuel and oil transfer, hydraulic lines, and even in some automotive and medical equipment. Their resistance to many chemicals, including oils, solvents, and fuels, makes them a practical choice in environments where exposure to these substances is common. Additionally, their smooth inner surface minimizes friction and pressure drop, ensuring efficient fluid or gas flow.

Braided Nylon Hose

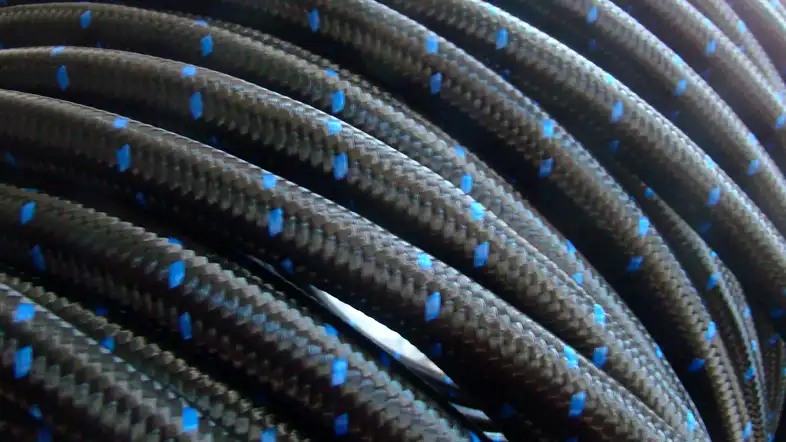

Braided nylon hoses are known for their lightweight and flexible nature. These hoses are composed of multiple layers of nylon and synthetic materials. Their flexibility makes them easy to handle and maneuver, making them ideal for various applications.

Braided nylon hoses are often used in automotive applications, such as fuel and brake lines, due to their durability and resistance to corrosion. They are also commonly found in pneumatic systems and hydraulic setups.

Braided nylon hoses are versatile and widely used in various applications. They are known for their flexibility, lightweight construction, and affordability. Here are some key characteristics of braided nylon hoses:

- Flexibility: One of the most significant advantages of braided nylon hoses is their flexibility. These hoses can bend and twist without kinking or collapsing, making them suitable for a wide range of applications where maneuverability is essential.

- Lightweight: Braided nylon hoses are significantly lighter than their stainless steel counterparts. This lightweight nature makes them easy to handle and install, reducing the physical strain on the user.

- Affordability: Compared to stainless steel hoses, braided nylon hoses are generally more budget-friendly. This cost-effectiveness makes them an attractive option for those working within tight budgets.

- Resistance to Corrosion: While nylon is not as corrosion-resistant as stainless steel, braided nylon hoses do offer decent resistance to corrosion, especially when compared to other materials like rubber hoses.

- Common Applications: Braided nylon hoses are commonly used in various industries, including automotive, pneumatic systems, and hydraulic systems, thanks to their versatility and flexibility.

Braided Stainless Hoses

Stainless hoses, on the other hand, are renowned for their unparalleled durability. Constructed from high-quality stainless steel, these hoses are resistant to corrosion, extreme temperatures, and pressure. This makes them suitable for applications where strength and longevity are paramount.

Stainless hoses are frequently employed in industrial settings, such as chemical plants and oil refineries, where they can withstand harsh conditions. They are also favored in food processing industries for their sanitary properties.

- Durability: Stainless steel hoses are incredibly durable and can withstand harsh environments, extreme temperatures, and high-pressure conditions. They are built to last, making them a long-term investment.

- High Temperature Resistance: Stainless steel hoses excel in high-temperature applications, where other materials may degrade or fail. Their ability to handle extreme heat makes them ideal for applications involving steam and hot liquids.

- Corrosion Resistance: One of the primary advantages of stainless steel hoses is their exceptional resistance to corrosion. They are virtually immune to rust and can withstand exposure to corrosive chemicals and liquids.

- Hygienic Applications: Stainless steel hoses are commonly used in food and pharmaceutical industries due to their hygienic properties. They are easy to clean and maintain, making them suitable for applications requiring strict cleanliness standards.

- Common Applications: Stainless steel hoses find applications in industries such as petrochemical, industrial, and manufacturing, where durability and resistance to extreme conditions are paramount.

Braided Nylon Hose vs Stainless

Both braided nylon and stainless steel hoses are popular choices for high-performance applications, but they differ significantly in key areas. This guide compares their properties to help you choose the right hose for your needs.

Durability and Strength

Braided nylon hoses are strong and lightweight, providing excellent resistance to abrasion and pressure. The nylon braiding protects the inner synthetic rubber tube from damage and kinking. While durable for most applications, they may not withstand the most extreme environmental stresses as well as stainless steel.

Stainless steel braided hoses offer superior durability and strength. The stainless steel wire mesh provides exceptional protection against cuts, abrasions, and high-impact damage. This makes them ideal for demanding environments where the hose might be exposed to sharp objects or constant friction.

Weight

One of the most significant advantages of braided nylon hoses is their light weight. The nylon material is considerably lighter than stainless steel, which can be a crucial factor in racing or aerospace applications where every ounce matters. This lighter weight also makes them easier to handle and install.

Stainless steel hoses are noticeably heavier than their nylon counterparts. This added weight can be a drawback in weight-sensitive applications. However, the increased heft is a direct result of their more robust construction, which contributes to their greater strength and durability.

Flexibility and Installation

Braided nylon hoses are highly flexible, making them easier to route and install in tight or complex spaces. Their pliability reduces the chance of kinking during installation and allows for more intricate hose routing without special tools. This flexibility is a major benefit for DIY enthusiasts and custom builds.

Stainless steel hoses are much more rigid and less flexible. This rigidity can make them more difficult to route and install, especially in confined areas. Special tools and careful planning are often required to bend and position them correctly to avoid kinking or stressing the fittings.

Cost

Braided nylon hoses are generally more affordable than stainless steel hoses. The materials and manufacturing processes for nylon are less expensive, making them a cost-effective choice for those on a budget or for large-scale projects where cost is a primary concern.

Stainless steel hoses come at a higher price point. The cost reflects the premium material and the more complex manufacturing process required to create the durable steel braid. This higher initial investment is often justified by their longer lifespan and superior performance in extreme conditions.

Appearance and Aesthetics

Braided nylon hoses offer a sleek, modern look, often with a subtle black or colored finish. This can be a more understated and clean aesthetic for an engine bay or system. Some manufacturers offer a variety of colors, allowing for a degree of customization.

Stainless steel hoses provide a classic, high-performance aesthetic. The shiny, metallic look is a favorite in the automotive and racing world, often associated with strength and quality. The visible steel braiding gives a rugged, industrial appearance that many enthusiasts find appealing.

| Feature | Braided Nylon Hose | Stainless Steel Hose |

| Durability | Good; resistant to abrasion and pressure | Excellent; superior resistance to cuts, abrasion, and impact |

| Weight | Lightweight | Heavier |

| Flexibility | High; easy to install and route | Low; rigid and can be difficult to route |

| Cost | More affordable | More expensive |

| Appearance | Sleek, modern, and often black | Classic, shiny, and industrial-looking |

How to Choose Braided Nylon Hose and Stainless Steel

Choosing between braided nylon and stainless steel hose depends on a careful evaluation of your specific project requirements. To make an informed decision, consider the following key factors:

- Application: For a standard street car or a project where weight savings are a priority, the flexibility and lightweight nature of braided nylon are often the best choice. For high-stress racing, off-road vehicles, or applications with significant heat and abrasion, the superior durability of stainless steel is likely the better investment.

- Budget: Braided nylon hoses are more budget-friendly, making them a great option for those who need a performance upgrade without a significant financial outlay. Stainless steel hoses, while more expensive, offer a longer lifespan and greater protection, which can be a cost-effective solution over time.

- Installation: If you are a DIY enthusiast working in a tight engine bay, the flexibility of a braided nylon hose will make installation much easier. In contrast, if you have the tools and patience for a more rigid setup and want the highest level of protection, stainless steel is a worthy consideration.

Can braided nylon hoses handle high-pressure applications?

While braided nylon hoses are durable, they are not designed for extremely high-pressure applications. Stainless hoses are a better choice for such scenarios.

Are stainless hoses safe for use in the food industry?

Yes, stainless hoses are commonly used in the food processing industry because they are easy to clean and maintain, ensuring sanitary conditions.

Are braided nylon hoses resistant to chemicals?

Braided nylon hoses have moderate chemical resistance, but for applications involving harsh chemicals, stainless hoses are a safer choice.

Which hose is more affordable?

Braided nylon hoses are generally more cost-effective upfront, but stainless hoses can offer long-term savings due to their durability.

Can stainless hoses handle extreme temperatures?

Yes, stainless hoses are highly resistant to extreme temperatures and are suitable for applications that involve both hot and cold environments.

Are braided nylon hoses suitable for automotive applications?

Yes, braided nylon hoses are commonly used in automotive applications like fuel and brake lines due to their flexibility and durability.

Conclusion

Ultimately, the best choice between braided nylon and stainless steel hose depends on your specific application. Braided nylon is a great option for those who need a lightweight, flexible hose that can handle high pressure while keeping costs down. It’s a fantastic choice for many street and racing applications where weight is a factor and the environment isn’t overly abrasive.

On the other hand, stainless steel braided hose is the champion of durability and extreme performance. While heavier and more rigid, its superior resistance to abrasion and heat makes it ideal for high-stress environments, such as a professional racing setup or an engine bay with high heat. The added protection is worth the investment for those who prioritize long-term reliability.

For your wholesale needs, consider Kingdaflex for nylon braided hoses. Our products offer a perfect blend of performance, flexibility, and affordability, making them a great choice for manufacturers and large-scale projects. Contact us today to explore our extensive range and find the right solution for your business.