We provide flat face hydraulic fittings that offer a leak-free connection. These fittings feature precise mating surfaces that create a seal without the need for gaskets or O-rings. This results in a more reliable and durable connection, reducing the risk of leaks and downtime in hydraulic systems.

We supply flat face O-ring fittings that combine the benefits of both flat face and O-ring sealing. These fittings utilize a precisely machined flat face for initial contact and an O-ring for the final seal. This hybrid approach ensures a reliable and leak-free connection, even under high pressure and demanding conditions.

We supply BSP (British Standard Pipe) flat face fittings, designed for high-pressure applications. These fittings utilize precise mating surfaces to create a leak-free seal without the need for gaskets or O-rings. This results in a robust and reliable connection, minimizing the risk of leaks and enhancing the overall performance of your hydraulic system.

We supply metric flat face hydraulic fittings designed for high-pressure applications. These fittings adhere to ISO standards, ensuring compatibility and interchangeability. They offer a reliable seal with minimal leakage, improving system efficiency and reducing maintenance costs.

We supply metric flat face hydraulic fittings designed for high-pressure applications. These fittings adhere to ISO standards, ensuring compatibility and interchangeability. They offer a reliable seal with minimal leakage, improving system efficiency and reducing maintenance costs.

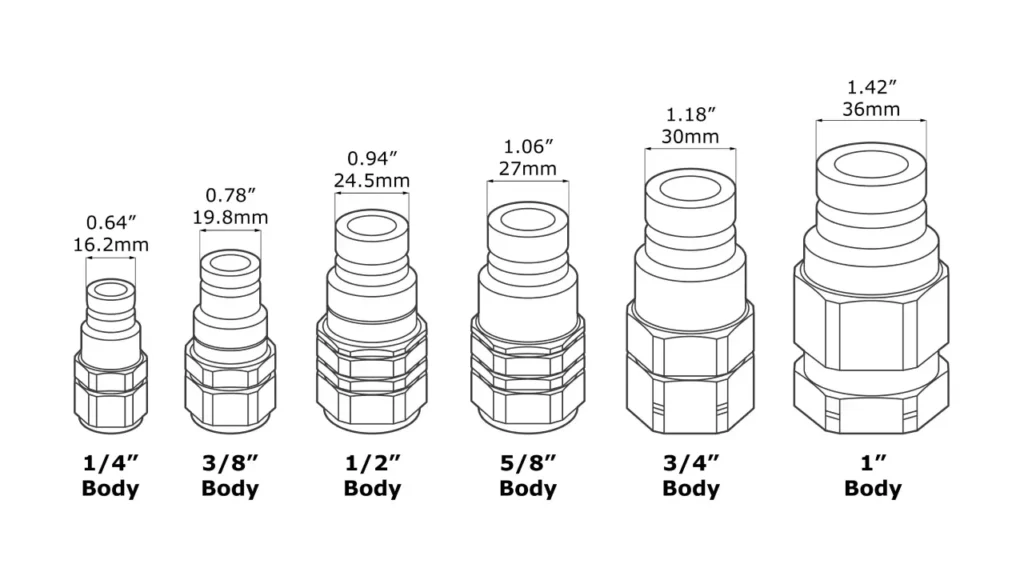

Flat face hydraulic fittings come in a variety of sizes, typically specified by their body size or port size.

Selecting the Right Size:

Choosing the correct size is crucial for proper system function and compatibility. Factors to consider include:

Flat face hydraulic fittings are specialized connectors used in hydraulic systems.

Key Characteristics:

Flat face hydraulic fittings are primarily used for:

In essence, they provide a reliable, efficient, and low-maintenance solution for connecting components in various hydraulic systems.

Here’s how to connect flat face hydraulic couplers:

Additional Tips:

1. Thread Size:

2. Body Size:

3. Sealing Face Diameter:

4. Other Relevant Dimensions:

Tools Needed:

Important Considerations:

By carefully measuring these dimensions, you can accurately identify and order the correct replacement fittings for your hydraulic system.