A hydraulic system works by transmitting power through pressurized fluid, allowing machinery to perform heavy-duty tasks with precision and control. These systems are widely used in industrial, automotive, and construction fields due to their ability to multiply force efficiently and deliver smooth, consistent motion in demanding environments.

Hydraulic systems consist of essential components such as pumps, valves, actuators, and hoses, all working together to convert hydraulic energy into mechanical power. Understanding how hydraulic systems function helps ensure optimal performance, safety, and longevity for various applications, from excavators and forklifts to aircraft and manufacturing equipment.

What is a Hydraulic System?

A hydraulic system is a mechanical setup that uses pressurized fluid to transmit power and perform work efficiently. It operates based on Pascal’s Law, allowing even small forces to generate powerful mechanical motion in machinery across construction, manufacturing, and automotive industries.

Main Components of a Hydraulic System:

- Hydraulic Pump: Converts mechanical energy into hydraulic energy by pressurizing the fluid and pushing it through the system to drive actuators and cylinders for motion and power generation.

- Hydraulic Fluid: Acts as the power transmission medium, lubricating moving parts, transferring heat, and ensuring smooth and efficient force movement throughout the entire hydraulic circuit.

- Hydraulic Cylinder: Converts hydraulic energy into linear motion and force, enabling heavy loads to be lifted, pushed, or pulled effectively in industrial and mobile equipment.

- Hydraulic Valves: Control the flow and direction of hydraulic fluid, managing pressure levels and system performance to ensure precise and safe machinery operation.

- Hydraulic Hoses: Flexible, durable tubes that transport hydraulic fluid between components, ensuring reliable pressure maintenance and fluid delivery even under high temperatures and harsh conditions.

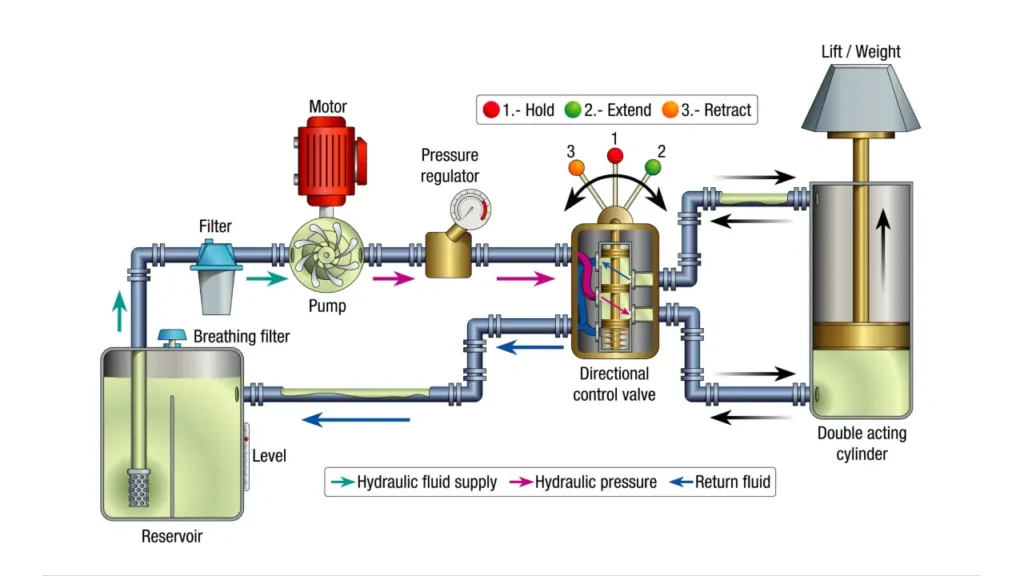

How Does a Hydraulic System Work?

A hydraulic system works by transmitting power through fluid pressure within sealed components. When a force is applied to the fluid by a pump, the pressure is distributed evenly, allowing large machinery to perform heavy lifting, movement, or control with remarkable precision and efficiency.

How a Hydraulic System Works

- Energy Conversion: The hydraulic pump converts mechanical energy into hydraulic energy by pushing the fluid into the system, creating a pressurized flow that powers various actuators and hydraulic devices effectively.

- Pressure Transmission: The pressurized fluid travels through hoses and valves, transmitting equal force in all directions, allowing the system to deliver consistent and controlled mechanical power to the target components.

- Actuator Movement: Hydraulic cylinders or motors receive the pressurized fluid and transform it into linear or rotary motion, providing strong and smooth operation for equipment like excavators, lifts, and presses.

- Flow Regulation: Valves within the system regulate pressure and fluid flow, maintaining stability and precision during operation while protecting components from damage caused by excessive force or pressure.

- Fluid Return: After performing its task, the hydraulic fluid flows back to the reservoir through return lines, where it cools and filters before being recirculated to begin the next working cycle efficiently.

How a Hydraulic Brake System Works?

A hydraulic brake system operates by using pressurized brake fluid to transfer force from the driver’s foot on the brake pedal to the wheel brakes. This process amplifies braking power, ensuring smooth, reliable, and efficient stopping performance for vehicles of all sizes and applications.

Working Steps of a Hydraulic Brake System:

- Brake Pedal Force: When the driver presses the brake pedal, mechanical force is applied to the master cylinder, converting foot pressure into hydraulic pressure within the brake lines instantly and efficiently.

- Master Cylinder Function: The master cylinder pushes brake fluid through the system, maintaining steady hydraulic pressure and evenly distributing force to all connected wheel cylinders or calipers for balanced braking action.

- Brake Fluid Pressure: The incompressible brake fluid transfers pressure through hoses and lines, ensuring instant response and consistent braking performance even under high temperatures or heavy load conditions.

- Wheel Cylinder or Caliper: At each wheel, hydraulic pressure forces pistons outward, pressing brake pads against rotors or shoes against drums, generating friction that slows or stops the wheel’s rotation.

- Return and Release: When the driver releases the pedal, the pressure in the system decreases, allowing the brake components to retract and the fluid to return to the reservoir for the next operation.

Hydraulic Hoses Used in Hydraulic Systems?

-

SAE 100R14 / Teflon Hose(Inner Corrugated Tube)

SAE 100R14 / Teflon Hose(Inner Corrugated Tube) -

SAE 100R6 | Hydraulic Hose

SAE 100R6 | Hydraulic Hose -

SAE 100R15 | Hydraulic Hose

SAE 100R15 | Hydraulic Hose -

SAE 100R13 | Hydraulic Hose

SAE 100R13 | Hydraulic Hose -

SAE 100R12 | 4 Wire Spiral Hydraulic Hose

SAE 100R12 | 4 Wire Spiral Hydraulic Hose -

SAE 100R9 | Hydraulic Hose

SAE 100R9 | Hydraulic Hose -

SAE 100R8 | Thermoplastic Hydraulic Hose

SAE 100R8 | Thermoplastic Hydraulic Hose -

SAE 100R7 | Thermoplastic Hydraulic Hose

SAE 100R7 | Thermoplastic Hydraulic Hose -

SAE 100R4 | Hydraulic Suction Hose

SAE 100R4 | Hydraulic Suction Hose -

SAE 100R3 Textile Fiber Reinforced Hydraulic Hose

SAE 100R3 Textile Fiber Reinforced Hydraulic Hose -

SAE 100 R14 / Teflon Hose (Inner Smooth Tube)

SAE 100 R14 / Teflon Hose (Inner Smooth Tube) -

SAE 100R5 | Fabric Covered Hydraulic Hose

SAE 100R5 | Fabric Covered Hydraulic Hose -

SAE 100R17 | Hydraulic Hose

SAE 100R17 | Hydraulic Hose -

SAE 100R16 | Hydraulic Hose

SAE 100R16 | Hydraulic Hose -

SAE 100R2A / DIN EN853 2ST

SAE 100R2A / DIN EN853 2ST -

SAE 100R1A/DIN EN853 1ST

SAE 100R1A/DIN EN853 1ST -

SAE 100R2AT / DIN EN853 2SN

SAE 100R2AT / DIN EN853 2SN -

SAE 100R1AT/ DIN EN853 1SN

SAE 100R1AT/ DIN EN853 1SN

Hydraulic hoses are flexible, high-pressure tubes designed to transmit hydraulic fluid between components within a hydraulic system. They play a vital role in maintaining pressure, ensuring safe fluid transfer, and allowing efficient movement in machinery used across industrial, agricultural, and construction applications.

Main Types of Hydraulic Hoses Used in Hydraulic Systems:

- High-Pressure Hydraulic Hose: Built to handle extreme pressure levels, these hoses deliver consistent fluid power to cylinders and actuators, ensuring strong and reliable performance in heavy-duty hydraulic systems.

- Steel Wire Braided Hose: Reinforced with one or more layers of steel wire braid, this hose provides superior flexibility and pressure resistance, ideal for mobile machinery and compact hydraulic applications.

- Spiral Wire Hydraulic Hose: Made with multiple spiral wire layers, it withstands high impulse loads and extreme conditions, making it perfect for excavators, tractors, and other heavy construction equipment.

- Thermoplastic Hydraulic Hose: Lightweight and abrasion-resistant, thermoplastic hoses are suitable for tight spaces and applications requiring chemical resistance, offering excellent performance and flexibility under various temperature conditions.

- Return Line Hydraulic Hose: Designed for low-pressure return flow, this hose channels used hydraulic fluid back to the reservoir, ensuring smooth recirculation and efficient cooling of the entire hydraulic system.

How Does a Tractor Hydraulic System Work?

A tractor hydraulic system uses pressurized fluid to power implements, lift loads, and operate attachments efficiently. By converting mechanical power from the tractor’s engine into hydraulic energy, it enables smooth control and high-performance operation for various agricultural and industrial applications.

Working Process of a Tractor Hydraulic System:

- Power Source: The tractor engine drives the hydraulic pump, converting mechanical energy into hydraulic pressure. This pressurized fluid becomes the main power source for lifting, steering, and controlling attached implements.

- Hydraulic Pump Operation: The pump circulates hydraulic fluid through the system, ensuring a constant flow and maintaining pressure required to move cylinders, valves, and other hydraulic components effectively.

- Control Valves: These valves direct the flow of pressurized fluid to specific parts, allowing the operator to lift, lower, tilt, or move equipment with precision and ease from the tractor seat.

- Hydraulic Cylinders: Cylinders convert hydraulic pressure into linear motion, enabling the tractor to perform heavy-duty tasks such as lifting plows, raising loaders, or adjusting the position of mounted implements.

- Fluid Return and Filtration: After completing its function, the hydraulic fluid returns to the reservoir, where it’s filtered to remove contaminants and cooled before recirculating through the system for continuous, efficient operation.

Conclusion

Hydraulic systems play a vital role in powering modern equipment, offering unmatched strength, efficiency, and precision. By understanding their operating principles, users can improve performance, minimize downtime, and ensure consistent output in industrial and mechanical applications that rely on fluid power.

Regular maintenance and selecting the right hydraulic components, especially hoses, are key to achieving safe and efficient operation. High-quality hoses prevent leaks, maintain pressure, and extend system lifespan, making them an essential part of any reliable hydraulic setup.

At Kingdaflex, we provide wholesale hydraulic hoses built to meet global standards for durability and performance. Whether you need hoses for construction, agriculture, or manufacturing equipment, our products ensure seamless hydraulic flow and lasting reliability. Partner with Kingdaflex to power your hydraulic systems efficiently and safely.