Hose whipping is one of the most common accident that occurs when operating a concrete pump. If you have never seen it happen on the job, check Youtube and you will see that this is no joke. The good news is that it can easily be prevented if you understand what can cause it and what simple measures to take.

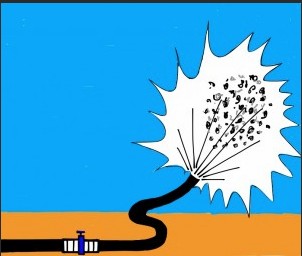

So, what is hose whipping? Simply put, it is the uncontrolled and rapid motion of a flexible rubber hose on the end of a concrete placement boom or other type of concrete delivery line.

What causes it?

Most of the time, it happens, when air enters the line and finds a blockage in the line. The pressure increases and whatever blocked the line shoots out violently. It can also be caused by the ready mix driver that lets the hopper go dry, or the pump operator who doesn’t realize the hopper has gone dry or has a plug in the line.

However, the risk can occur way before the concrete comes out of the system. If, when the system starts up, the air comes into the line and the operator pushes a concrete mix that contains too much rocks, the pipe and hose will be dry and not yet primed. Some loose components are separated from the rest of the mix by air, creating pressure and a block. When the boom is connected to one or more lay-down rubber hoses, the danger is even greater.

Another common situation that has most operators tend to ignore is whenever you stop pumping and restart. It accounts for about 50% of these accidents because the reality on the job is that pumps stops dozens of times a day. If after stopping, a small amount of concrete come out, it means that the line is lubricated. However, since it is rare that the air in the line can trigger a hose whip, workers tend to downplay the risk and not stay away from the end of the hose when restarting pumping. Big mistake and again so easily preventable!

When does hose whipping happen?

Either during priming, pumping operation or when cleaning out the system. In other words, anytime the pump is on!

Dangers for the crew

Workers can either be directly hit by the hose, knocked over by it or injured by material that is ejected. It all happens really quickly and violently.

What Should Be Done to ensure that hose whipping never happens?

Here are some practical tips from the pros that have seen just about everything on the job site:

ALWAYS…

1. Use properly trained professional pump operators.

2. Keep workers away from the hose at least in the first one-half yard of pumping.

3. Use quality air clamp on hose end.

4. Limit reductions as much as possible. Use a steel reducer, if you have to.

5.Have a person monitor the hopper and shut the pump in the event air is sucked into the line (it isn’t the delivery truck driver’s responsibility!)

6. Pump a little slower so that you can catch when your turn your strokes down or put it in reverse to expel the air out.

7. Use smaller rocks on smaller hoses to reduce block and releases in reducer.

8. Use safety gear: glasses, helmet, gloves etc.

If any needs for the concrete hose, please contact us.

Tel: +86-532-88799936

Fax:+86-532-80867065

Email: [email protected]

Skype: kingdaflex

Whatsapp: 008618562767380