Cutting a hydraulic brake hose properly is essential for ensuring safe and efficient braking performance. Improper cuts can lead to leaks, reduced pressure, or brake failure. In this guide, we’ll walk you through the necessary tools, techniques, and safety precautions to achieve clean, precise cuts every time.

Understanding the structure and materials of hydraulic brake hoses is key before cutting. Different hoses require specific tools and methods to maintain integrity and performance. By following proper procedures, you can customize hose lengths for vehicles, trailers, or machinery while ensuring long-lasting reliability and optimal brake system operation.

What are Hydraulic Brake Hoses?

Hydraulic brake hoses are flexible tubes that carry brake fluid from the master cylinder to the brake calipers or wheel cylinders in a vehicle’s braking system. They transmit hydraulic pressure efficiently, allowing smooth and responsive braking while accommodating movement, vibrations, and alignment changes between components.

How to Cut Hydraulic Brake Hose?

Cutting a hydraulic brake hose correctly is vital for ensuring reliable brake performance and safety. Following precise steps prevents leaks, maintains hydraulic pressure, and guarantees smooth operation. Using the right tools and techniques ensures a professional, durable result every time.

Step 1: Gather Tools and Safety Gear

Before starting, collect all necessary tools including a hydraulic brake hose cutter, measuring tape, marker, and fittings. We also recommend protective gloves and safety glasses to shield hands and eyes from sharp edges, debris, or fluid exposure.

Proper preparation ensures a smooth workflow and reduces mistakes. Having all tools ready allows you to work efficiently, maintain focus on accuracy, and prevent damage to the hydraulic brake hose or surrounding components while performing precise cuts.

Step 2: Measure and Mark the Hydraulic Brake Hose

Accurate measurement is crucial for a proper hydraulic brake hose fit. We measure the required length and use a fine-tip marker to indicate the cutting point, ensuring that the hydraulic brake hose will connect correctly without tension or slack in the brake system.

Marking the hydraulic brake hose clearly prevents miscuts and reduces waste. This step allows for precise placement of fittings and ensures the hydraulic brake hose maintains consistent hydraulic pressure, which is critical for safe and responsive braking performance.

Step 3: Secure the Hydraulic Brake Hose

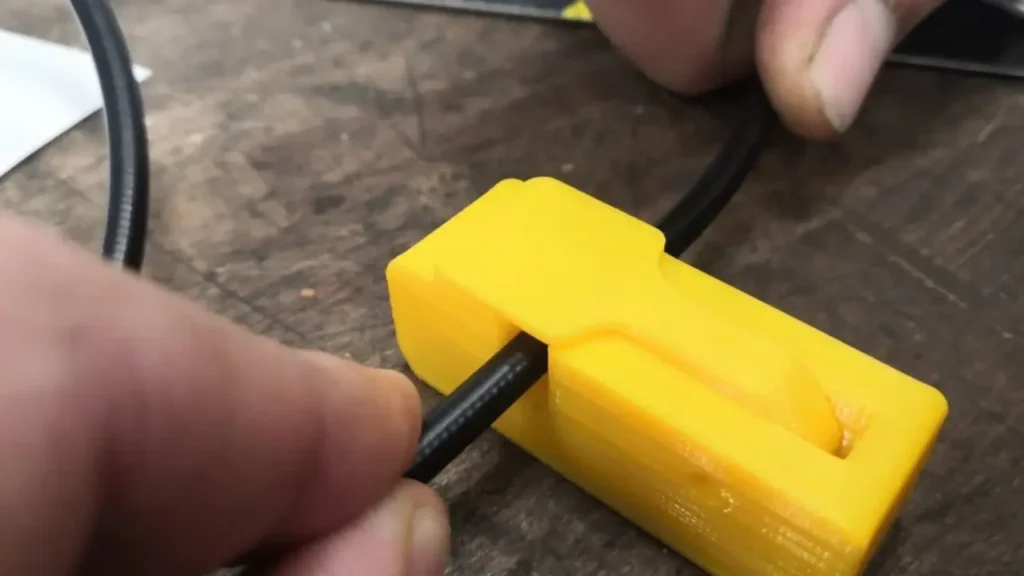

To avoid slipping or uneven cuts, we firmly secure the hydraulic brake hose using a vise or appropriate clamp. This stability ensures that the cut is straight and the hydraulic brake hose’s structure remains intact during the cutting process.

Properly securing the hydraulic brake hose also prevents kinks, deformation, or internal damage. By keeping the hydraulic brake hose steady, we can make a clean, accurate cut, which is essential for creating a reliable, leak-free connection with the fittings.

Step 4: Use the Correct Cutter

Selecting the proper hydraulic brake hose cutter is essential. We position the cutter carefully, applying even pressure to prevent crushing or fraying. Using the right tool ensures the hydraulic brake hose’s internal tubing stays intact for optimal fluid flow.

A precise cutter allows for a smooth edge that simplifies fitting attachment. It minimizes the risk of leaks or weak connections, ensuring the hydraulic brake hose system maintains consistent pressure and performance for long-term reliability.

Step 5: Make the Cut Slowly

We cut the hydraulic brake hose in a controlled, steady motion, avoiding forceful or rushed movements. This careful approach prevents jagged edges and maintains the hydraulic brake hose’s integrity, which is vital for a secure and leak-free hydraulic system.

Slow, deliberate cutting reduces the chance of internal damage or frayed fibers. This ensures a professional finish, improves the reliability of the fittings, and contributes to consistent hydraulic brake hose performance under high pressure.

Step 6: Inspect the Cut End

After cutting, we inspect the hydraulic brake hose end for smoothness, straightness, and any signs of fraying or cracks. This quality check ensures the hydraulic brake hose is ready for fitting attachment without risking leaks.

If imperfections are found, we trim or correct them before proceeding. Proper inspection guarantees the hydraulic brake hose maintains pressure integrity, prevents fluid loss, and supports safe, responsive braking performance.

Step 7: Attach Fittings and Install Hydraulic Brake Hose

We attach the appropriate fittings following manufacturer specifications, ensuring tight, leak-proof connections. Properly installed fittings maintain hydraulic pressure and prevent fluid leaks under high braking loads.

Once fitted, the hydraulic brake hose is carefully installed in the brake system. This final step completes the process, ensuring safe, efficient, and reliable braking performance while maintaining the hydraulic brake hose’s long-term durability and operational integrity.

What are Hydraulic Brake Hoses Made of?

Hydraulic brake hoses are carefully engineered using multiple layers of durable materials to ensure safety, flexibility, and long-lasting performance. Each layer serves a specific purpose, from fluid transmission to pressure resistance and external protection, allowing reliable operation under high pressure, vibration, and extreme environmental conditions.

- Inner Tube: The inner tube is made from synthetic rubber or thermoplastic, resistant to brake fluid and maintaining flexibility. We design it to ensure smooth fluid flow, prevent leaks, and provide consistent braking performance under various temperatures and pressures, ensuring safety and reliability.

- Reinforcement Layer: The reinforcement layer typically consists of braided steel, synthetic fibers, or fabric. We use it to enhance pressure resistance, prevent expansion under load, and maintain structural integrity, ensuring the hose performs reliably under heavy braking and extreme operating conditions.

- Outer Cover: The outer cover is made from abrasion-resistant synthetic rubber or thermoplastic. We apply it to protect the hose from heat, chemicals, UV exposure, and physical damage, extending lifespan while maintaining flexibility, durability, and consistent hydraulic performance.

- Fittings and Connectors: Fittings are usually steel, brass, or aluminum, designed to create secure, leak-proof connections. We ensure they fit precisely, maintain pressure integrity, and allow easy installation, providing a safe, reliable hydraulic pathway from the master cylinder to brake components.

- Optional Protective Coatings: Additional coatings, such as nylon or polymer layers, may be applied for extra protection. We use these to guard against abrasion, environmental damage, and chemical exposure, enhancing durability and maintaining consistent performance throughout the hose’s service life.

Where to Use Hydraulic Brake Hoses?

Hydraulic brake hoses are critical components in braking systems, transferring brake fluid under pressure to ensure smooth, responsive stopping. They are used in a wide range of vehicles and machinery, providing flexibility and reliability where rigid lines cannot accommodate movement, vibration, or alignment changes.

- Passenger Vehicles: We use hydraulic brake hoses in cars, SUVs, and light trucks to connect the master cylinder to wheel brakes. This ensures smooth pedal response, consistent stopping power, and reliable braking performance for daily driving and varying road conditions.

- Commercial Trucks and Trailers: Hydraulic brake hoses in heavy-duty trucks and trailers handle higher pressures and longer lengths. We provide hoses designed for durability and reliability, ensuring consistent braking performance under heavy loads and demanding commercial transport conditions.

- Motorcycles and ATVs: These hoses are applied in motorcycles, scooters, and all-terrain vehicles, providing flexible connections between brake levers and calipers. We ensure hoses maintain precise pressure control, delivering responsive braking even in high-speed or off-road scenarios.

- Industrial and Agricultural Machinery: Hydraulic brake hoses are used in tractors, forklifts, and other machinery. We supply hoses that resist chemicals, heat, and abrasion while maintaining hydraulic pressure, supporting safe, efficient operation in challenging work environments.

- Specialty and Racing Vehicles: High-performance and racing vehicles use hydraulic brake hoses for precise, rapid response. We design hoses to withstand extreme pressure, heat, and dynamic movements, ensuring consistent brake performance under competitive or high-stress conditions.

Conclusion

Cutting hydraulic brake hoses correctly is crucial for vehicle safety and system efficiency. Using the right tools and techniques ensures a precise, leak-free connection, enhancing brake performance. Always follow manufacturer guidelines and safety precautions to avoid potential hazards and maintain consistent system pressure.

At Kingdaflex, we provide a wide selection of hydraulic brake hoses suitable for various vehicles and industrial applications. Our hoses are durable, reliable, and designed to handle high pressure, offering a seamless solution for your cutting, installation, and replacement needs.

For wholesale hydraulic brake hoses, trust Kingdaflex to supply quality products in bulk. We cater to businesses, workshops, and distributors, providing competitive pricing, reliable delivery, and hoses that meet diverse requirements. Get the right hoses to keep your braking systems safe and efficient.