Something especially important is that how to identify hydraulic hoses.

What Is A Hydraulic Hose Used for?

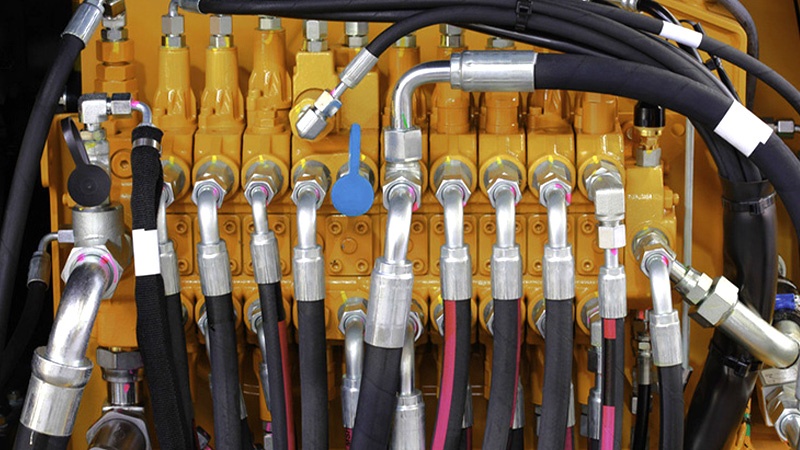

The hydraulic hose can be widely used for various vehicles, machinery, and you can be clear about the hydraulic hose applications before hydraulic hose assemblies. A hydraulic hose can be used anywhere in a hydraulic system, requiring a flexible connection between two fluid ports.

A hydraulic hose is a synthetic rubber tube designed with flexibility and strength, enhancing winding, and the rubber material is so strong that it can’t be broken easily while bending. The reinforcement windings of the hydraulic hoses can give the hose its flexibility and strength, and these reinforcements can be either braided or spiral wounds.

And hydraulic hoses can be categorized as spiral hydraulic hoses and braided hydraulic hoses, and you can get the differences between spiral & braided hydraulic hoses.

The hydraulic hose is made of synthetic rubber material, and it can be applied to many fields, including construction, building projects, government construction projects, agricultural machinery, etc. So the hydraulic hose plays an important role in the facilities construction, improving the level for our daily work & life.

How to Identify Hydraulic Hoses?

So it is important for us to identify hydraulic hoses, here are some tips.

Identify the size of the hydraulic hose

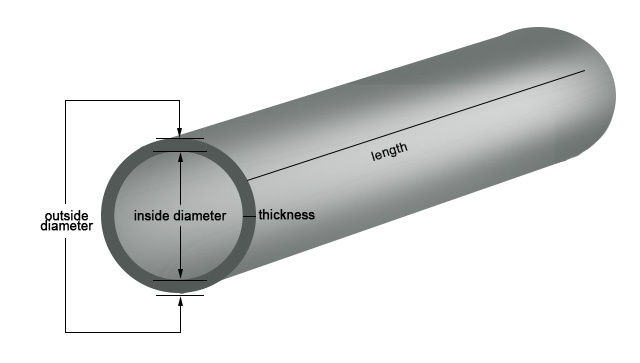

The size of the hydraulic hose is basically important for the hydraulic systems, seriously related to the safety issues. And we have to measure the hydraulic hose before assembling the hydraulic hose, to ensure the most accurate size. We need to use the precision measuring tool – vernier caliper to get the result.

And we can use two nomenclatures: Nominal diameter and Inches to read the measuring result.

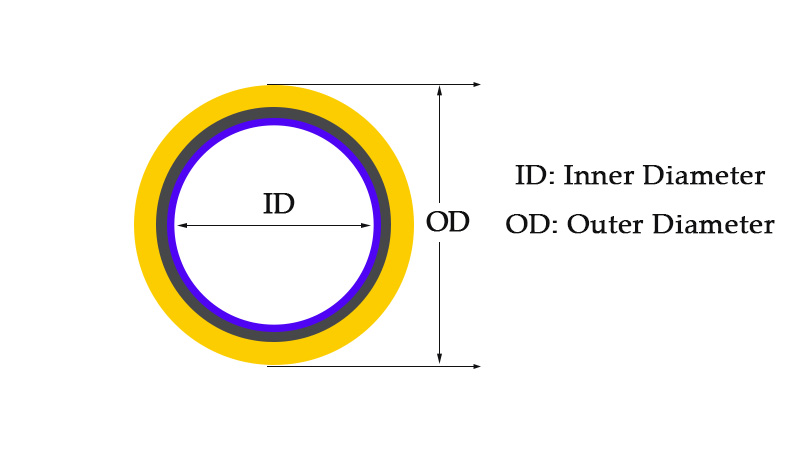

Here are some parameters measuring the hydraulic hose for you to find the right hydraulic hose for your hydraulic project. Here are some basic important parameters for you to identify the hydraulic hose size, including inside diameter (ID), outside diameter (OD), and length, the thickness of a hydraulic hose can also be considered to determine the durability.

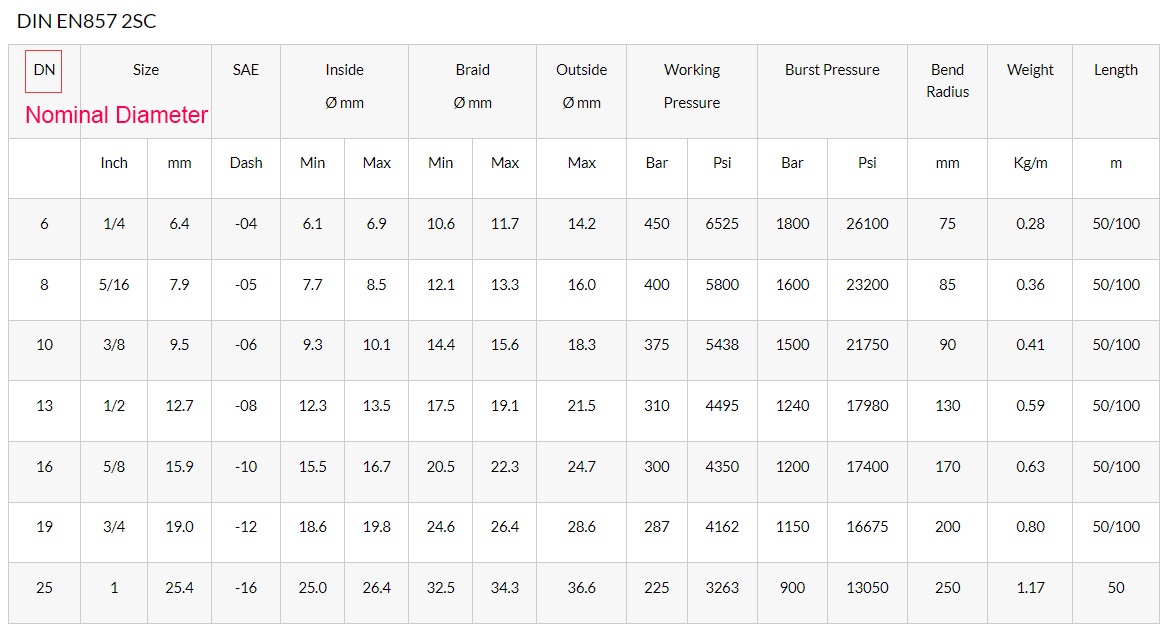

What is DN in Hydraulic Hose?

What is hose DN? DN is the abbreviation of Nominal Diameter. DN is the measurement in millimeters of the interior of the hose. This measurement of length comes from the English nomenclature. 1 inch equals 25.40 millimeters, also the inside of the hose as a reference.

You can use the vernier caliper to measure the hydraulic hose to get the hydraulic hose DN size, and there will be the hydraulic hose specification chart on the detailed page. It is helpful for you to get your desired hydraulic hose pipe in the right size.

How to Identify Hydraulic Hose Fittings?

What are hydraulic hose fittings? The hydraulic hose fittings are used to connect the hoses to pumps, valves, cylinders, and other components used through the hydraulic working system. So the hydraulic hose fittings’ important connections help contain and flow the hydraulic fluid to where it is should be while preventing leaks at the same time.

So it is also important to identify the right hydraulic fittings to connect the hydraulic hoses together to convey the fluid well, ensure safety and efficiency. Here are some useful tips on how to identify good hydraulic hose fittings for your hydraulic system.

Determine the right type of the hydraulic hose fittings

Here are 2 types of hydraulic hose fittings for the hydraulic hose connection, permanent hydraulic hose fittings, and reusable hydraulic hose fittings.

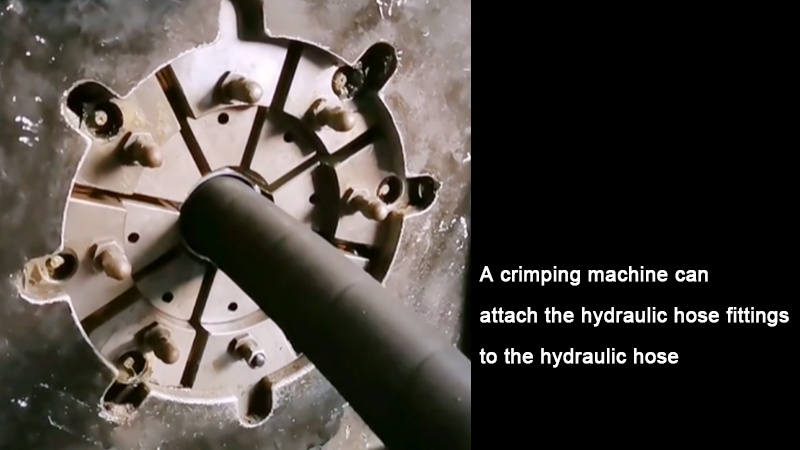

Permanent hydraulic hose fittings (or crimped fittings) are the more common hydraulic hose fittings. These need a crimping machine in order to attach them to a hose. They are easy to replace and remove, and they are the most reliable type of hydraulic hose fitting.

Reusable hydraulic fittings connect to a hose with a wrench and a vise. This type of hydraulic hose fitting is often left on the shelf due to its steeper cost and time-consuming assembly process.

Identify the hydraulic hose fitting ends for port connections

| Port Connections | Hose Connections |

| NPT/NPTF BSPT (JIS-PT) Metric Taper SAE Straight Thread ISO 6149 JIS-B2351 DIN Metric BSPP (JIS-PF) 4-Bolt Flange |

37⁰ Flare 30⁰ Flare (Metric) 45⁰ Flare 24⁰ Flareless (SAE) 24⁰ Flareless (DIN) 30⁰ Flare (BSPP) O-Ring Face Seal (ORFS) 60⁰ NPSM Swivel 60⁰ Cone (BSPP) 60⁰ Cone (Metric) |

The chart above can share with you how to identify the fitting ends and port connections

Identity the hydraulic hose fittings sealing method

Hydraulic hose fittings have many different types, and they are varied in sizes, configurations, and thread types. You need to learn to identify the hydraulic hose fitting sealing method to connect the hydraulic hoses for the hydraulic project. O-ring sealing is the most popular sealing method, and for more detailed info, please feel free to contact us to get more.

Identity the hydraulic hose fitting design

Then it is also important to identify the hydraulic hose fittings design, to know the location of the O-ring, nose seat, seat angle, and fitting termination. Overall, all of these can help you identify the suitable hydraulic hose fittings for your hydraulic hose connections.

Once you find your sealing method of the hydraulic hose fittings, the next task is to observe the positions of the O-Ring, fitting termination, nose seat, and seat angle.

In order to decide your seat angle, you will need a seat gauge. Note that female seats are often difficult to measure. You can determine a male seat’s measurements by positioning the gauge on the sealing surface as the connection and gauge are parallel.

Depending on your sealing method your O-Ring may be on the inside, outside, in the flange groove, or at the nose seat. Your nose seat may be inverted, flat face, or standard.

How to Identify Thread on Hydraulic Hose Fittings

It is important to identify the size of the hydraulic hose fitting thread sizes, to find the right thread to combine the hydraulic hoses together for the whole hydraulic project.