The hydraulic hose is the construction material used to convey the substances for the construction project, such as oil, water, fluids, gas, and so on. So hydraulic hoses have wide applications, including Petroleum-based hydraulic fluid, gasoline, water, diesel fuels, lubricating oils, glycol, mineral oils, and etc.

Here are many different types of hydraulic hose in the industry, and today we are going to share with you guys the differences between spiral vs braided hydraulic hose.

What Is A Spiral Hydraulic Hose?

The spiral hydraulic hose consists of two, three, four, or more layers of helically wrapped high tensile steel wire that can add much more strength, to make the hydraulic hose become very strong, but the spiral hydraulic hose is also rigid, not easy to bend.

And the hydraulic hose is designed with a high tensile steel wire spiral that can make work well under high pressure, with high resistance to high pressure compared with the braided hydraulic hose.

In order to be used for many applications in high-pressure environment, we can make many layers of steel wire reinforcement to add strength to the hydraulic hose. Here we have a 4-wire spiral hydraulic hose, 6-wire spiral hydraulic hose and etc.

And the spiral hydraulic hose with more layers of helically wrapped steel wire will bear higher pressure, and there are also many different diameters of the hydraulic hose pipe for your options. It’s flexible for you to get your desired spiral hydraulic hose for your hydraulic project.

What Is A Braided Hydraulic Hose?

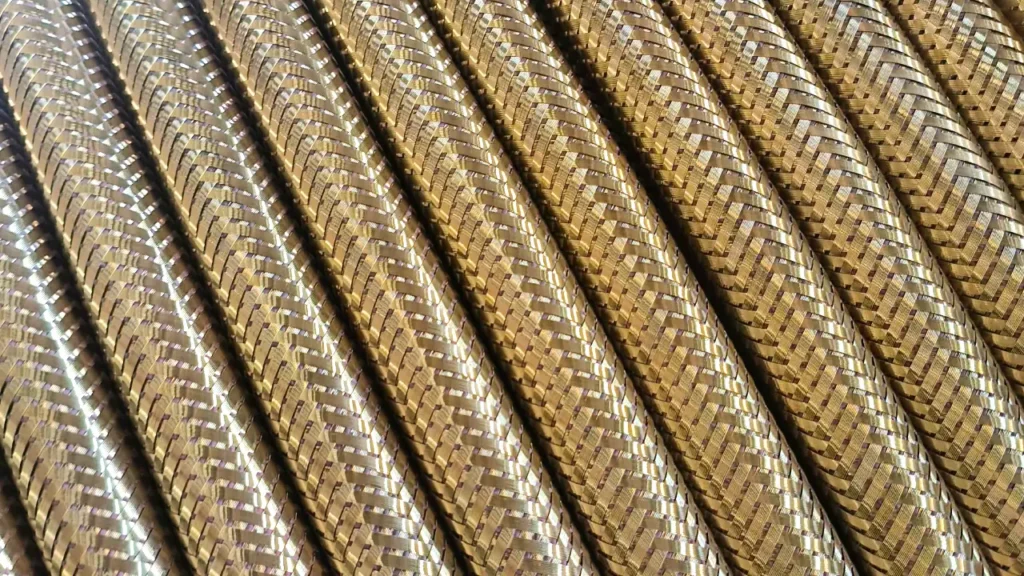

A wire braided hydraulic hose consists of braided and woven high tensile steel wires overlapping one another to reinforce the tube. Our hydraulic hose manufacturer will use the advanced hydraulic hose braiding machine to braid the steel wire to create the braided reinforcement for the hydraulic hose.

And the hydraulic hose braiding machine will perform the braiding task to create braiding steel wire reinforcement during the manufacturing process, to produce the stainless steel braided hydraulic hose. And the braided hydraulic hose can increase the burst resistance to the hydraulic hose tube, and also add more flexibility to the hose pipe.

The steel braided hydraulic hose consists of braided steel wire to add much more strength to the whole hydraulic hose, making it much more durable and solid.

Here we have multiple choices for you to choose the steel braided hydraulic hose reinforced with different layers of steel wire. The more braided steel wire can add more strength to the hydraulic hose pipe.

And the crisscrossing braided wire reinforcement can make the hydraulic hose become more flexible, much easier to bend compared with a spiral hydraulic hose.

Spiral vs Braided Hydraulic Hose

You can determine to choose a spiral hydraulic hose or braided hydraulic hose based on your applications. And you can watch the video below to know the differences between them in the manufacturing process.

Due to the hydraulic hose structure, the braided hydraulic hose can provide more flexibility due to its low bend radius with the help of criss-cross braided steel wire physical performance. The braided hose can present better application for the hydraulic hose assemblies, even you have to assemble your braided hydraulic hose in the tight spaced hydraulic system.

The braided reinforcement of the hydraulic hose can make it much more flexible for you to locate it for a better hydraulic hose routing.

The spiral hydraulic hose is reinforced with spiral steel wire, the spiral-constructed steel reinforcement can remain parallel, wrapping the hydraulic hose firmly, making it solid and not easy to bend over.

Compared with the braided hydraulic hose, the spiral hydraulic hose has much less flexibility, but with better maximum pressure capacity. So that you can use the spiral hydraulic hose for the heavy-duty machine due to the spiral hose’s high strength.

Both of these two hydraulic hoses are manufactured with certain functions, and you only need to choose the suitable hydraulic hose for your hydraulic system, making it work better for your hydraulic project.

Here’s a table outlining the differences between spiral and braided hydraulic hoses:

| Aspect | Braided Hydraulic Hose | Spiral Hydraulic Hose |

|---|---|---|

| Design | Braid-like pattern with alternating steel wires. | Spiral-like pattern with parallel steel wires. |

| Ease of Production | Requires heavy machinery for production. | Relatively easier and faster to manufacture. |

| Strength | High tensile strength due to interlocking wires. | Requires more spiral wires for pressure resistance. |

| Application | Suited for high-tensile strength applications. | Ideal for high-pressure applications. |

| Flexibility | Relatively flexible. | Relatively rigid. |

| Bend Radius | Tighter bend radius. | Highly resistant to bending. |

| Popularity | More common in hydraulic applications. | Less common in hydraulic applications. |

| Adaptability | Works in small spaces with tighter bend radius. | Not suitable for space-limited applications. |

This table should help provide a clear overview of the differences between spiral and braided hydraulic hoses.

What is the Difference Between Spiral and Braided Reinforcement?

The main difference between spiral and braided reinforcement lies in their structural design and how they provide strength to hoses:

Braided Reinforcement:

- Design: Braided reinforcement consists of steel wires arranged in an interlocking, crisscross pattern around the inner tube of the hose.

- Strength: The interlocking design of the steel wires provides high tensile strength to the hose. This design helps the hose withstand internal and external pressures.

- Flexibility: Braided reinforcement offers relative flexibility, allowing the hose to bend and move more easily.

- Applications: Braided reinforcement is suitable for applications that require high tensile strength, such as industrial and hydraulic systems. It is commonly used in medium-pressure hoses.

Spiral Reinforcement:

- Design: Spiral reinforcement involves steel wires arranged in a parallel spiral pattern around the inner tube of the hose.

- Strength: The parallel spiral arrangement of steel wires provides greater structural integrity, enabling the hose to handle higher pressures and resist collapsing under suction.

- Rigidity: Spiral reinforcement results in a relatively rigid hose structure, making it less flexible than braided hoses.

- Applications: Spiral reinforcement is ideal for high-pressure applications, such as heavy machinery, construction equipment, and applications where suction resistance is essential.

In a word, braided reinforcement offers flexibility and is suitable for applications requiring moderate strength, while spiral reinforcement provides increased strength and is better suited for high-pressure and suction-resistant applications. The choice between the two depends on the specific requirements of the application and the level of pressure the hose needs to withstand.

Braided Hydraulic Hose or Spiral, Which is Bette

The best choice between braided and spiral hydraulic hoses depends on the specific requirements of your application. Here’s a breakdown to help you decide:

- Pros:

- Flexibility: Excellent for applications requiring tight bends and frequent movement.

- Durability: Resists abrasion and vibration.

- Wide range of applications: Suitable for various hydraulic systems, including those in construction, agriculture, and manufacturing.

- Cons:

- Lower pressure rating: Typically less suitable for extremely high-pressure applications.

- Pros:

- High-pressure resistance: Ideal for applications with high-pressure surges and impulses.

- Durability: Resistant to wear and tear, particularly in harsh environments.

- Cons:

- Less flexible: Not as suitable for applications requiring frequent bending.

Key Considerations for Choosing the Right Hydraulic Hose:

- Pressure Rating: Ensure the hose can handle the maximum pressure your system will experience.

- Temperature Range: Consider the operating temperature to select a hose with appropriate temperature resistance.

- Fluid Compatibility: Choose a hose compatible with the fluid being used (e.g., hydraulic oil, water-based fluids).

- Flexibility: If your application requires frequent bending, a braided hose is a better choice. For high-pressure, straight-line applications, a spiral hose is more suitable.

- Abrasion Resistance: Consider the environment the hose will be exposed to and select a hose with adequate abrasion resistance.

In conclusion, both braided and spiral hydraulic hoses have their strengths and weaknesses. By carefully considering your specific application requirements, you can choose the right hose to ensure optimal performance and longevity of your hydraulic system.

Need Our Hydraulic Hose Expert Advice?

If you’re unsure which type of hose is best for your application, consult with a hydraulic hose specialist. They can provide expert guidance and help you select the right product.

Conclusion

Choosing between spiral and braided hydraulic hoses depends on the specific requirements of your application.

Spiral hoses offer superior pressure resistance and are ideal for high-pressure applications where flexibility is not a major concern. Braided hoses, on the other hand, excel in flexibility and are suitable for applications that require frequent bending and movement.

Ready to upgrade your hydraulic system?

Kingdaflex offers a wide range of high-quality spiral and braided hydraulic hoses to meet your specific needs. Contact us today to discuss your application and find the perfect hose solution.