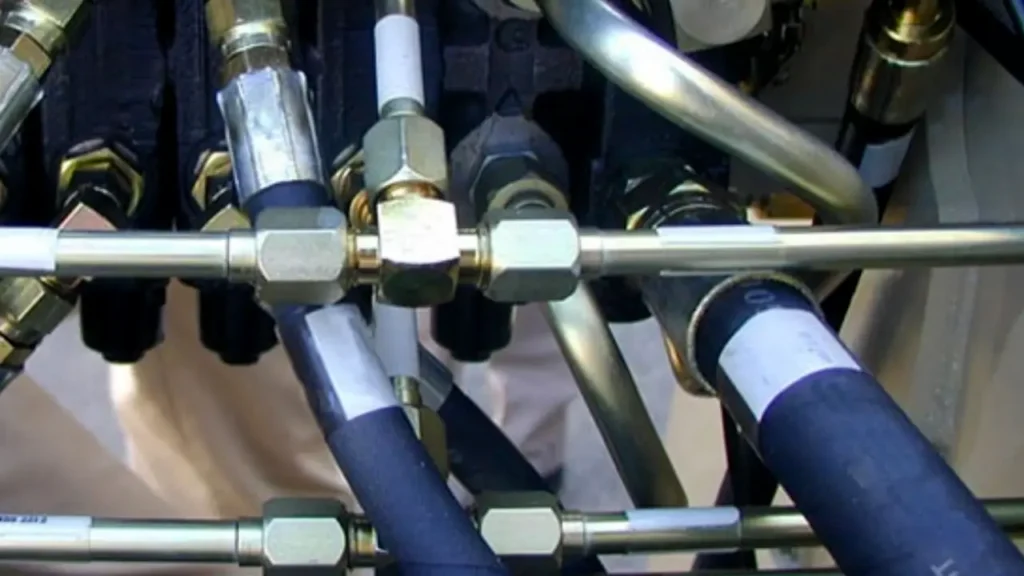

Hydraulic hoses are an essential component in many industries, powering machinery and equipment with the force of hydraulic fluid. However, over time, these hydraulic hoses can become stuck or difficult to remove, posing a challenge for maintenance and repair tasks.

In this article, we will guide you through the process of removing a stuck hydraulic hose efficiently and safely. Whether you are a professional technician or a DIY enthusiast, this step-by-step guide will help you tackle this common issue effectively.

Importance of Hydraulic Hose Safety

Hydraulic hoses are critical components in industrial, automotive, and machinery systems. Ensuring their safe use protects equipment, operators, and the environment. Neglecting hose safety can lead to leaks, system failures, or serious injuries, making proper handling, inspection, and maintenance essential for reliable performance.

- Prevent Equipment Damage: Hydraulic hose failure can cause fluid leaks, pressure loss, or mechanical malfunctions. Regular inspections and proper installation prevent costly damage, maintain system efficiency, and reduce downtime. Properly maintained hoses ensure smooth operation and protect valuable machinery from unexpected breakdowns.

- Ensure Operator Safety: High-pressure hydraulic fluid can cause severe injuries if hoses rupture. Adhering to safety protocols, using protective equipment, and inspecting hoses regularly minimizes risks. Safe handling and operation protect workers from accidents, punctures, or exposure to hazardous fluids during maintenance or use.

- Maintain System Efficiency: Leaks or hose degradation reduce hydraulic system performance, affecting productivity. Ensuring hoses are properly rated, installed, and maintained keeps pressure stable and fluid flow consistent, optimizing energy use and operational efficiency across machinery, vehicles, and industrial systems.

- Extend Hose Lifespan: Proper storage, installation, and pressure management prevent premature wear, cracks, or bursting. Maintaining safety standards reduces replacement frequency, saves costs, and ensures hoses perform reliably over time, providing long-term durability even in high-pressure or harsh operating conditions.

- Compliance and Liability Protection: Following safety regulations and manufacturer guidelines minimizes legal risks and liability. Proper documentation of inspections, maintenance, and replacements demonstrates adherence to safety standards, protecting businesses from fines, lawsuits, and reputational damage while promoting a culture of workplace safety.

How to Remove a Stuck Hydraulic Hose?

Removing a stuck hydraulic hose requires care, proper tools, and safety precautions. Improper handling can damage fittings, hoses, or equipment and may cause injury. Following step-by-step procedures ensures safe and efficient removal while preserving the hose and system components.

Here are some steps basically important about how to get a stuck hydraulic hose off.

Applying Penetrating Lubricants to Loosen the Hose

Step 1: Relieve System Pressure

Before attempting removal, ensure the hydraulic system is completely depressurized. Open bleed valves or follow manufacturer-recommended procedures to release trapped fluid safely. This prevents sudden fluid ejection, which can cause injuries or damage to surrounding equipment.

Confirm that all pressure indicators show zero and that fluid has stopped moving. Never attempt to remove a hose under pressure, as even small amounts of high-pressure hydraulic fluid can penetrate skin or damage components, creating a serious safety hazard.

Step 2: Clean the Connection Area

Clean the area around the hose connection to remove dirt, grease, or debris. This prevents contaminants from entering the hydraulic system during removal and reduces the risk of cross-threading or damage to fittings.

Use appropriate cleaning tools and solutions to ensure a clear workspace. A clean surface improves grip, visibility, and control, making it easier to loosen fittings without slipping, scratching, or damaging threads on connectors or adapters.

Step 3: Apply Penetrating Oil

If the hose fitting is corroded or stuck, apply a suitable penetrating oil. Let it soak for several minutes to loosen rust, mineral deposits, or hardened debris that may be preventing smooth removal.

Ensure even application around threads and fittings. The oil reduces friction and softens deposits, allowing you to turn the fitting with less effort while minimizing the risk of stripping threads or damaging the hose.

Step 4: Use Proper Tools

Select wrenches or spanners that fit the hose fittings precisely. Using the correct tools ensures torque is applied evenly, reducing the risk of rounding off fittings or damaging connectors. Avoid using adjustable wrenches if possible.

Apply steady, controlled force rather than sudden jerks. If a fitting doesn’t move easily, double-check for residual pressure, trapped fluid, or remaining corrosion. Using proper tools prevents accidents and preserves the integrity of both hose and equipment.

Step 5: Gently Twist and Pull

Once loosened, gently twist the hose back and forth while pulling to gradually free it from the fitting. Avoid excessive force, which can damage threads or the hose itself, especially on older or worn components.

Maintain a secure grip and consistent motion. Slowly working the hose free prevents sudden release, which can cause injuries or fluid spills. Patience is key to safely removing a stuck hydraulic hose without causing damage.

Step 6: Inspect and Replace if Necessary

After removal, inspect the hose and fittings for wear, cracks, or damage. Replace any components showing signs of deterioration to maintain system safety, efficiency, and reliability. Do not reuse hoses that are compromised.

Check for clean, undamaged threads on both hose and connector. Proper inspection ensures that the reinstalled or replacement hose will perform reliably under pressure, preventing leaks, system failures, and safety hazards in future operation.

Tips to Prevent Stuck Hydraulic Hoses

Preventing hydraulic hoses from getting stuck saves time, reduces maintenance costs, and ensures system reliability. By following proper installation, maintenance, and handling practices, you can minimize wear, corrosion, and contamination, keeping hoses functioning smoothly and reducing the risk of costly downtime or damage.

- Regular Inspection and Maintenance: Routinely check hoses and fittings for wear, corrosion, and leaks. Early detection of issues allows timely replacement or adjustment, preventing hoses from seizing. Consistent maintenance ensures the hydraulic system operates efficiently and extends the service life of hoses and connectors.

- Proper Installation Techniques: Always use the correct tools and follow manufacturer guidelines during installation. Ensure hoses are aligned without twisting or bending sharply, and tighten fittings to the recommended torque. Proper installation reduces stress on hoses, preventing them from sticking or becoming difficult to remove.

- Use Lubrication When Needed: Applying appropriate lubricants or anti-seize compounds to fittings can prevent rust, corrosion, and adhesion. This helps hoses and connectors remain flexible and easy to remove during maintenance, reducing the risk of stuck hoses and preserving system performance over time.

- Avoid Excessive Pressure and Heat: Operating hoses beyond their rated pressure or exposing them to extreme heat accelerates wear and may cause fittings to seize. Maintaining proper system parameters protects hoses, prevents deformation, and ensures safe, reliable operation in industrial or automotive applications.

- Store Hoses Properly: When hoses are not in use, store them in a clean, dry environment away from direct sunlight, chemicals, or extreme temperatures. Proper storage maintains hose flexibility, prevents corrosion, and minimizes the risk of them sticking to fittings or developing damage over time.

How to Remove Hydraulic Hose Fittings

Removing hydraulic hose fittings requires some caution and the right tools. Here’s a general guide to get you started:

Tools:

- Two wrenches (sizes will depend on the fitting)

- Rags

- Optional: Heat gun (for stubborn fittings)

Steps about removing hydraulic hose fittings

- Identify the type of fitting: Hydraulic hoses use various fittings. Knowing the specific type will help you determine the removal process. However, the general steps are similar for most.

- Prepare the workspace: Place the equipment on a stable surface and ensure you have enough space to maneuver the wrenches.

- Contain the fluid: Hydraulic fluid can be messy and potentially harmful. Place a container underneath the hose connection to catch any drips.

- Clean the connection: Wipe off any dirt or debris around the fitting to avoid contaminating the hydraulic system.

- Loosen the fittings: Use two wrenches. One wrench will hold the stationary part of the coupling (the body of the fitting on the machine). The other wrench will turn the fitting that connects to the hose. By holding the stationary part, you ensure you’re loosening the threaded connection, not twisting the hose itself.

- Be aware of stubborn fittings: If the fitting is stuck, apply gentle heat with a heat gun to the metal fitting, not the hose. The heat can cause the metal to expand and loosen its grip on the hose.

- Twist and pull: As you loosen the fitting, you can also try a gentle twisting motion on the hose while applying pulling force. This can help break any adhesion or corrosion.

Safety precautions:

- Wear safety glasses to protect your eyes from any debris or fluid splashes.

- Be mindful of the pressure in the hydraulic system. If you’re unsure, consult a professional.

- Don’t reuse old hoses or fittings if they are damaged.

Additional tips:

- If you’re unsure about any of the steps, consult a mechanic or someone familiar with hydraulic systems.

- There are resources online and video tutorials [YouTube] that can provide a more visual guide to removing hydraulic hose fittings specific to your equipment.

Remember, this is a general guide, and the specific steps may vary depending on the type of fitting and your equipment. If you’re not comfortable doing this yourself, it’s always best to consult a professional.

Conclusion

Removing a stuck hydraulic hose may seem challenging, but with the right tools, techniques, and precautions, it can be accomplished effectively. Remember to prioritize safety, gather the necessary tools, and follow the step-by-step guide outlined in this article.

By doing so, you’ll be able to tackle stuck hydraulic hoses confidently and efficiently, ensuring smooth operations in your hydraulic systems.

How long do hydraulic hoses typically last?

Hydraulic hoses’ lifespan depends on several factors, such as operating conditions, maintenance practices, and the quality of the hoses. On average, well-maintained hydraulic hoses can last anywhere from 5 to 10 years.

Can I repair a damaged hydraulic hose myself?

It is generally recommended to have damaged hydraulic hoses repaired or replaced by professionals. Hydraulic systems operate under high pressure, and improper repairs can lead to safety hazards and system failures.

Are there any safety precautions I should follow when using hydraulic hoses?

No, hydraulic hoses come in various sizes, typically measured by their inside diameter (ID). The size of the hose depends on the flow rate and pressure requirements of the hydraulic system.

What is the typical warranty period for hydraulic hoses?

Warranty periods for hydraulic hoses can vary depending on the manufacturer and the specific product. It’s advisable to check with the supplier or refer to the product documentation for warranty information.

Are there any environmentally friendly hydraulic hose options available?

Yes, some manufacturers offer hydraulic hoses made from environmentally friendly materials, such as bio-based oils and recyclable components. These options can help reduce the ecological impact of hydraulic systems.

How much does it cost to have hydraulic hoses made?

If you’re wondering about the cost of having hydraulic hoses made, several factors come into play.

How much hydraulic hose will depend on various elements, including the type of hose, its length and diameter, the material composition, and any additional customization requirements?

Additionally, the cost may vary based on the supplier or the location where the hoses are being made. To obtain an accurate estimate, it’s recommended to reach out to reputable suppliers and provide them with specific details about your hydraulic hose needs.

This way, they can provide you with a personalized quote that aligns with your requirements. Keep in mind that investing in high-quality, durable hoses may have long-term cost benefits, as they tend to offer better performance and longevity.