Hydraulic hoses play a crucial role in various industries and applications, allowing the transfer of fluid power within hydraulic systems. If you’re unfamiliar with the process of ordering hydraulic hoses, this comprehensive guide will walk you through the necessary steps.

We will cover the components of hydraulic hoses, the different types of hydraulic hose available, determining your specific requirements, choosing the right material and fittings, as well as tips for placing an order.

Getting Started

Hydraulic hoses are vital components in hydraulic systems as they transmit fluid power from one part of the system to another. Whether you’re working with heavy machinery, construction equipment, or even a hydraulic car lift, understanding how to order the correct hydraulic hose is essential to ensure efficient operation and prevent potential accidents.

Understanding Hydraulic Hoses

Components of a Hydraulic Hose

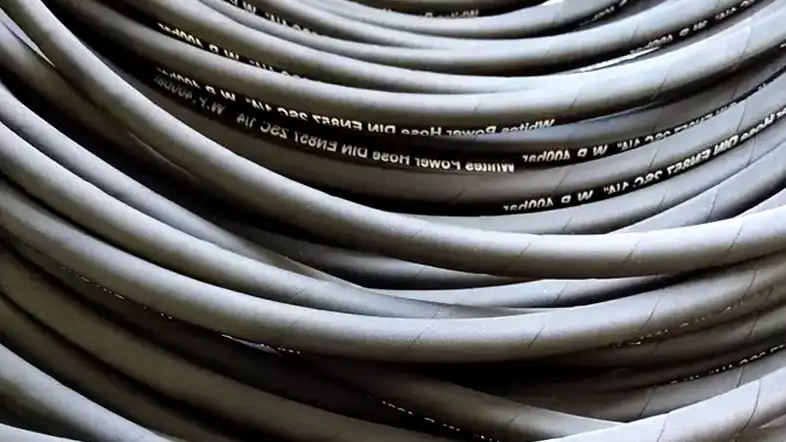

A hydraulic hose consists of three essential components: inner tube, reinforcement, and cover. The tube carries the fluid and prevents leakage. The reinforcement layer provides strength and structural integrity, usually made of high-tensile steel wire braids or spirals.

Lastly, the cover protects the hose from external damage, such as abrasion, weather, and chemicals.

Types of Hydraulic Hoses

Hydraulic hoses come in various types, each designed for specific applications and operating conditions. Some common types include:

- R1/R2: These hoses are suitable for general hydraulic applications with medium pressure requirements.

- R5: Ideal for applications with high temperatures and high pressure pulsations.

- R12/R13: These hoses are designed for heavy-duty applications that require high pressure and resistance to abrasion.

- R15: Specifically designed for extremely high-pressure applications, such as construction machinery and hydraulic lifts.

Understanding the different types of hydraulic hoses ensures that you select the one best suited for your specific needs.

Determining Your Hydraulic Hose Requirements

Before ordering a hydraulic hose, it’s crucial to determine your specific requirements. Here are two essential factors to consider:

Assessing Pressure and Temperature Requirements

The operating pressure and temperature of your hydraulic system greatly influence the selection of the appropriate hose. Consult the manufacturer’s specifications or seek professional advice to ensure the hose can handle the pressure and temperature ranges required for your application. Failure to do so may result in hose failure or compromised system performance.

Identifying Hose Size and Length

Determining the correct hydraulic hose size and length is equally important. Hose size refers to the inside diameter (ID) of the hose, while hose length should be appropriate for the distance between the connected components.

Measure the hydraulic hose if available or consult equipment manuals to determine the required size and length accurately.

It’s advisable to consult with a hydraulic expert or supplier to confirm your hose requirements for complex systems or unique applications.

Selecting the Right Hose Material

The selection of the right hose material is crucial for long-lasting performance and compatibility with the fluid being conveyed. Consider the following factors when choosing the hose material:

- Fluid Compatibility: Ensure the hose material is compatible with the fluid in your hydraulic system. Different materials may react chemically with certain fluids, causing hose degradation or failure.

- Temperature Range: Consider the minimum and maximum temperature limits the hose will encounter. Some materials may become brittle in cold temperatures, while others may deteriorate under high heat.

- Environmental Factors: Assess the exposure to environmental elements such as UV radiation, chemicals, or abrasive substances. Choose a hose material that can withstand these conditions to ensure longevity.

Consult with hydraulic experts or suppliers to identify the most suitable hose material for your specific application.

Choosing Hose Fittings and Connections

Proper hose fittings and connections are critical to ensure a secure and leak-free hydraulic system. Consider the following when selecting fittings:

Understanding Fitting Types

There are several types of hydraulic hose fittings available, including:

- Bite-type: Commonly used fittings that provide excellent sealing and resistance to vibration.

- Threaded: These fittings screw directly onto the hose, providing a secure connection.

- Flange: Suitable for high-pressure applications, flange fittings provide a robust connection.

Ensure compatibility between the hose and fittings, and choose the appropriate fitting type based on the application’s requirements.

Proper Connection Methods

Proper installation and connection methods are essential to prevent leaks and ensure optimal performance. Follow these steps:

- Measure and cut the hose to the required length.

- Clean both the hose and fittings to remove any debris or contaminants.

- Lubricate the hose and fitting surfaces to facilitate assembly.

- Insert the hose into the fitting until it reaches the metal crimping collar.

- Use a crimping machine to apply pressure evenly around the collar, securing the hose to the fitting.

Following these guidelines will help ensure a reliable and leak-free hydraulic system.

Placing an Order

When it’s time to order your hydraulic hose, consider the following tips:

Finding Reputable Suppliers

Research and identify reputable suppliers with a track record of providing high-quality hydraulic hoses and related products. Look for suppliers that offer a wide range of options and have positive customer reviews. Reach out to them for assistance in selecting the right hose for your application.

Providing Accurate Specifications

To ensure you receive the correct hydraulic hose, provide accurate specifications to the supplier. Include details such as the type of hose, required length, fitting types, and any additional requirements specific to your application. Clear communication and accurate specifications will help the supplier fulfill your order accurately.

Kindaflex Hydraulic Hose Manufacturer

Kingdaflex is a reputable hydraulic hose manufacturer. We specialize in producing high-quality hoses that are designed to withstand the demanding conditions of hydraulic systems. Kingdaflex hydraulic hoses are known for their durability, flexibility, and superior performance.

With a focus on precision engineering and stringent quality control measures, we ensure that hydraulic hoses meet industry standards and provide reliable functionality. Our hydraulic hoses are constructed using premium materials that are resistant to abrasion, corrosion, and extreme temperatures, allowing them to maintain optimal performance even in harsh environments.

We offer a wide range of hydraulic hoses to cater to various applications and requirements. Whether it’s for construction, agriculture, mining, or industrial purposes, their hoses are designed to deliver efficient fluid transfer and provide a secure and leak-free connection.

As a trusted hydraulic hose manufacturer, Kingdaflex prioritizes customer satisfaction by offering excellent service, prompt delivery, and technical support. Their commitment to producing top-notch hydraulic hoses has made them a preferred choice for many industries and hydraulic system operators.

When it comes to reliable and durable hydraulic hoses, we can stand out as a reputable manufacturer that delivers qualified hydraulic hoses that meet the needs of diverse hydraulic applications.

Conclusion

Ordering hydraulic hoses may seem overwhelming at first, but understanding the necessary steps can simplify the process.

By considering factors such as hose components, types, pressure and temperature requirements, material selection, fitting types, and proper installation methods, you can confidently order hydraulic hoses that meet your specific needs.

Remember to consult with hydraulic experts or reputable suppliers to ensure you make informed decisions.

Frequently Asked Questions (FAQs)

How long do hydraulic hoses typically last?

Hydraulic hoses’ lifespan depends on several factors, such as operating conditions, maintenance practices, and the quality of the hoses. On average, well-maintained hydraulic hoses can last anywhere from 5 to 10 years.

Can I repair a damaged hydraulic hose myself?

It is generally recommended to have damaged hydraulic hoses repaired or replaced by professionals. Hydraulic systems operate under high pressure, and improper repairs can lead to safety hazards and system failures.

Are there any safety precautions I should follow when using hydraulic hoses?

No, hydraulic hoses come in various sizes, typically measured by their inside diameter (ID). The size of the hose depends on the flow rate and pressure requirements of the hydraulic system.

What is the typical warranty period for hydraulic hoses?

Warranty periods for hydraulic hoses can vary depending on the manufacturer and the specific product. It’s advisable to check with the supplier or refer to the product documentation for warranty information.

Are there any environmentally friendly hydraulic hose options available?

Yes, some manufacturers offer hydraulic hoses made from environmentally friendly materials, such as bio-based oils and recyclable components. These options can help reduce the ecological impact of hydraulic systems.

How much does it cost to have hydraulic hoses made?

If you’re wondering about the cost of having hydraulic hoses made, several factors come into play.

How much hydraulic hose will depend on various elements, including the type of hose, its length and diameter, the material composition, and any additional customization requirements?

Additionally, the cost may vary based on the supplier or the location where the hoses are being made. To obtain an accurate estimate, it’s recommended to reach out to reputable suppliers and provide them with specific details about your hydraulic hose needs.

This way, they can provide you with a personalized quote that aligns with your requirements. Keep in mind that investing in high-quality, durable hoses may have long-term cost benefits, as they tend to offer better performance and longevity.

By following these guidelines and understanding the importance of hydraulic hose selection, you can confidently order hydraulic hoses that meet your needs and ensure the smooth operation of your hydraulic systems.