When it comes to hydraulic systems, hydraulic hose specifications play a critical role in ensuring optimal performance and safety. Hydraulic hoses are essential components that transmit fluid power within hydraulic machinery and equipment.

They must be designed and manufactured to meet specific requirements to withstand high-pressure conditions, deliver fluid efficiently, and withstand various environmental factors.

In this comprehensive guide, we will explore the key aspects of hydraulic hose specifications, including their construction, materials, pressure ratings, fittings, and more. So let’s dive in and understand the intricacies of hydraulic hose specifications!

Understanding Hydraulic Hose Specifications

Hydraulic hose specifications refer to the detailed requirements and characteristics that define the performance and capabilities of a hydraulic hose.

These specifications encompass a range of parameters, including hydraulic hose size, pressure rating, temperature range, flexibility, reinforcement type, and more.

Understanding these specifications is crucial for selecting the right hydraulic hose for a specific application. Let’s explore each aspect in detail.

Construction of Hydraulic Hoses

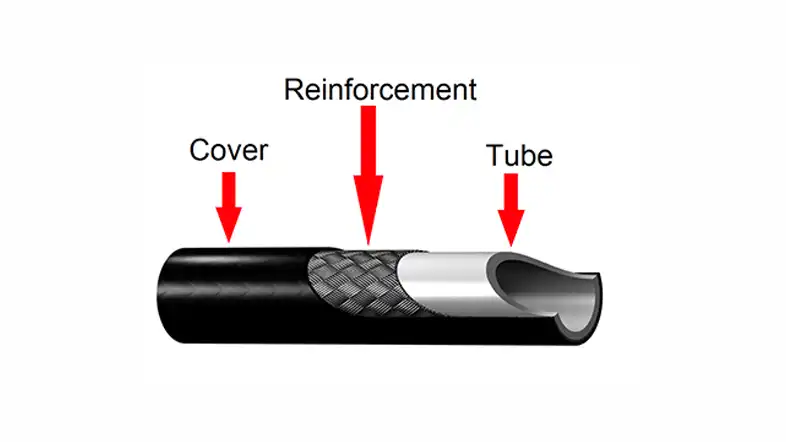

Hydraulic hoses are typically constructed using three layers: the inner tube, reinforcement layer, and outer cover. Each layer serves a specific purpose to ensure the hose’s durability, flexibility, and resistance to pressure and external factors. The inner tube provides a smooth passage for fluid flow, while the reinforcement layer, commonly made of high-tensile steel wire, enhances the hose’s strength. The outer cover protects the hose from abrasion, chemicals, and environmental elements. This robust construction enables hydraulic hoses to withstand demanding operating conditions.

SAE Hydraulic Hose Specifications

SAE (Society of Automotive Engineers) hydraulic hose specifications are widely used in the industry to ensure the compatibility and performance of hydraulic hoses.

The SAE has established standards for various aspects of hydraulic hoses, including size, construction, pressure ratings, and testing methods.

Here are some key specifications commonly associated with SAE hydraulic hoses:

- SAE 100R1: This specification refers to a single wire braid hydraulic hose with a working pressure of 1,000 psi (pounds per square inch). It is commonly used in low to medium pressure applications.

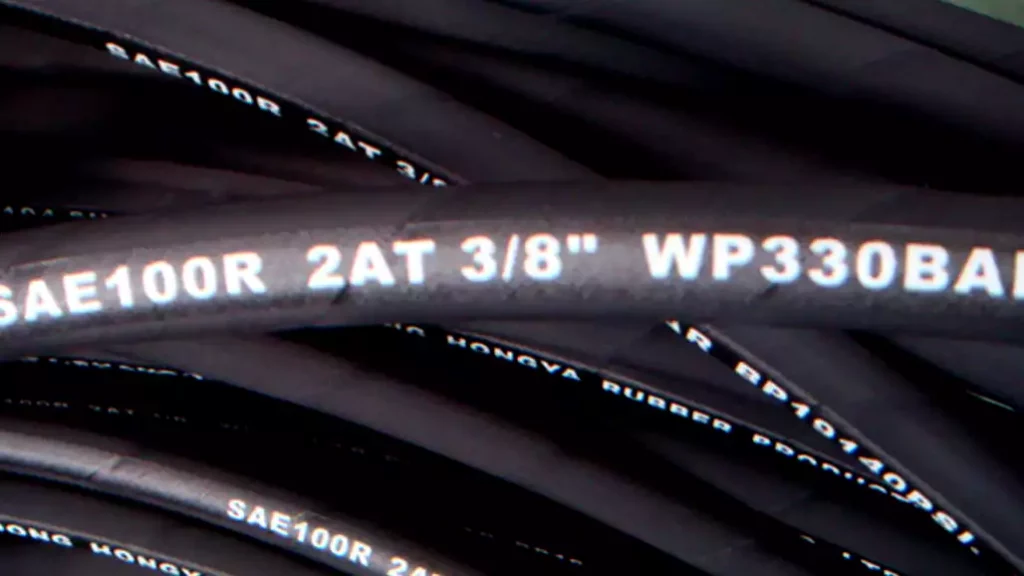

- SAE 100R2: This specification refers to a double wire braid hydraulic hose with a working pressure of 4,000 psi. It is suitable for high-pressure applications and provides increased strength and durability compared to SAE 100R1 hoses.

- SAE 100R3: This specification covers textile-reinforced hydraulic hoses. These hoses are commonly used in applications where low pressure and flexibility are required.

- SAE 100R4: This specification covers hydraulic suction and return line hoses. These hoses are designed for low-pressure hydraulic systems and provide excellent flexibility.

- SAE 100R5: This specification covers textile-covered hydraulic hoses with one or multiple wire braids. They are used in a wide range of applications, including medium pressure and temperature hydraulic systems, air brakes, fuel, and lubricating oil lines.

- SAE 100R6: This specification covers hydraulic hoses with a textile braid and a working pressure of 500 psi. They are commonly used in low-pressure applications and are suitable for petroleum-based hydraulic fluids and lubricating oils.

- SAE 100R7: This specification covers thermoplastic hydraulic hoses with a maximum working pressure of 3,000 psi. These hoses are typically used in high-pressure applications, such as hydraulic lifts and mobile equipment.

- SAE 100R12: This specification covers high-pressure, four-spiral wire-reinforced hydraulic hoses with a working pressure of up to 4,000 psi. They are suitable for heavy-duty applications requiring excellent impulse and abrasion resistance.

- SAE 100R13: This specification covers high-pressure, six-spiral wire-reinforced hydraulic hoses with a working pressure of up to 5,000 psi. They are commonly used in applications where extreme pressure and heavy-duty performance are required.

These are just a few examples of SAE hydraulic hose specifications. It’s important to refer to the specific SAE standard or the manufacturer’s documentation for detailed information on the specifications, including dimensions, temperature range, construction materials, and compatibility with various fluids.

Materials Used in Hydraulic Hoses

The choice of materials for hydraulic hoses is crucial to their performance and longevity. The inner tube material should be compatible with the type of fluid being conveyed to prevent degradation or chemical reactions. Common materials include synthetic rubber, thermoplastics, or a combination of both. The reinforcement layer, usually made of steel wire, provides strength and structural integrity. For the outer cover, materials such as synthetic rubber, polyurethane, or thermoplastic elastomers are used, depending on the desired characteristics and environmental conditions.

Pressure Ratings and Burst Limits

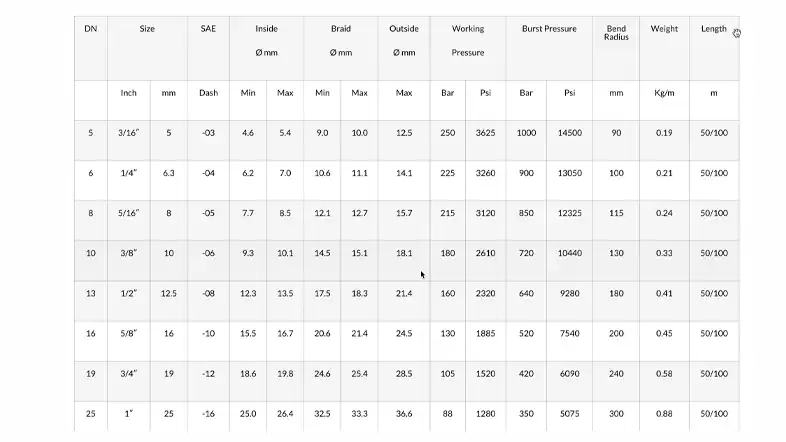

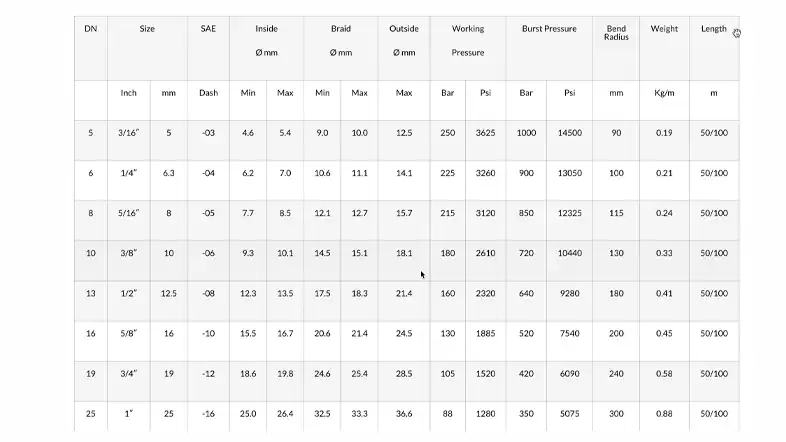

Hydraulic hoses are designed to handle specific pressure ratings, which determine the maximum pressure the hose can withstand without failure. The pressure rating is closely related to the hose’s size, reinforcement type, and construction.

The hydraulic hose bursting pressure is 4 times to hydraulic hose working pressure.

It is crucial to select a hose with an appropriate pressure rating that matches or exceeds the maximum working pressure of the hydraulic system.

Hydraulic hoses have a burst limit, which indicates the pressure at which the hose is likely to rupture. Operating within the specified pressure limits is essential for safety and optimal performance.

Selecting the Right Hydraulic Hose

Choosing the right hydraulic hose involves considering several factors to ensure compatibility and performance. Factors to consider include the required pressure rating, temperature range, compatibility with the conveyed fluid, environmental conditions, flexibility requirements, and industry standards. By carefully assessing these factors and consulting hydraulic system experts, you can select the most suitable hydraulic hose for your application, minimizing the risk of downtime, leaks, or other system failures.

Hydraulic Hose Fittings

Hydraulic hose fittings are crucial components that connect the hose to other system elements, such as pumps, valves, cylinders, and adapters. The fittings must provide a secure and leak-free connection while accommodating the hose’s size, type, and end configuration. There are various types of fittings available, including crimped fittings, reusable fittings, and quick-connect fittings. Proper installation of fittings is essential for maintaining the integrity and performance of the hydraulic system.

Installation and Maintenance

Proper installation and regular maintenance are vital for ensuring the longevity and performance of hydraulic hoses. During installation, it is crucial to route and secure the hoses properly, considering factors such as bend radius, vibration, and abrasion risks. Regular inspections, leak checks, and preventive maintenance help identify potential issues before they escalate into major problems. Following manufacturer guidelines and industry best practices for installation and maintenance will extend the life of hydraulic hoses and promote overall system efficiency.

Common Hydraulic Hose Problems

Despite their robust construction, hydraulic hoses can experience certain issues over time. It is important to be aware of common problems and address them promptly to avoid system failures or safety hazards.

Some common hydraulic hose problems include abrasion, hydraulic hose leaks, kinking, twisting, fluid contamination, and degradation due to excessive heat or chemical exposure. Regular inspections, timely repairs, and proper preventive measures can mitigate these problems and ensure the reliable performance of hydraulic systems.

FAQs

What are the key factors to consider when selecting hydraulic hoses?

When selecting hydraulic hoses, it is important to consider factors such as pressure rating, temperature range, compatibility with conveyed fluid, flexibility requirements, and industry standards.

How do I determine the appropriate hose size for my hydraulic system?

The appropriate hose size depends on factors such as flow rate, velocity, and pressure drop. Consulting hydraulic system experts or referring to industry guidelines can help determine the optimal hose size.

Can I use the same hydraulic hose for different types of fluids?

No, it is crucial to use a hydraulic hose that is compatible with the specific type of fluid being conveyed to prevent degradation or chemical reactions.

How often should I inspect my hydraulic hoses?

Regular inspections are recommended, and the frequency may vary depending on factors such as operating conditions, usage intensity, and manufacturer recommendations. However, a visual inspection should be performed at least monthly.

What are the signs of hydraulic hose failure?

Signs of hydraulic hose failure include leaks, cracks, bulges, abrasion marks, or any visible damage to the hose. Spongy or soft hoses, fluid leaks, and decreased system performance are also indications of potential hose problems.

Can hydraulic hoses be repaired, or should they be replaced?

Minor damages may be repairable using proper techniques and materials. However, severe damages or signs of degradation usually require hose replacement to maintain system safety and performance.

Conclusion

Hydraulic hose specifications are vital for ensuring the efficient and safe operation of hydraulic systems. By understanding the key aspects of hydraulic hose construction, materials, pressure ratings, fittings, and maintenance practices, you can make informed decisions when selecting, installing, and maintaining hydraulic hoses.

Remember to follow industry best practices, consult experts when needed, and prioritize regular inspections to mitigate potential issues and maximize the performance and lifespan of your hydraulic systems.