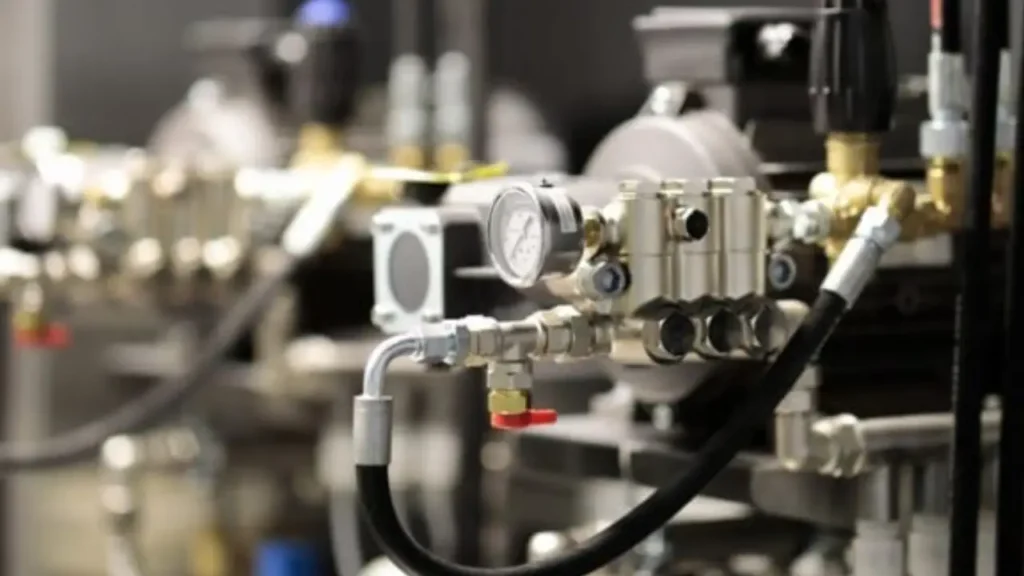

A sudden hydraulic hose burst can bring operations to a halt, leading to costly downtime, equipment damage, and serious safety risks. Understanding the underlying causes of hose failure is crucial for proactive maintenance and preventing unexpected catastrophes. It’s not just about replacing a broken hose; it’s about identifying the root cause.

By exploring the primary culprits behind hydraulic hose bursts, you can develop more effective preventive strategies. This guide will walk you through common issues—from improper installation and fluid incompatibility to external damage and aging—helping you implement best practices to extend hose life and enhance system reliability.

What Causes Hydraulic Hose Burst?

Why do hydraulic hoses burst?

A hydraulic hose can burst due to a combination of factors, often stemming from improper use, environmental stress, or manufacturing defects. Understanding these causes is crucial for preventing equipment failure and ensuring a safe working environment. The primary culprits include exceeding the hose’s pressure limits, external abrasion, improper hydraulic hose installation, and fluid incompatibility.

- Excessive Pressure: The most common cause of a burst is operating the hydraulic system at a pressure higher than the hose’s rated working pressure. This can be due to a faulty pressure relief valve, system surges, or an incorrect hose selection for the application.

- External Abrasion: Constant rubbing against other components, sharp edges, or surfaces can wear down the outer cover, exposing the reinforcement layers to damage and eventually causing a leak or burst.

- Extreme Temperatures: Operating a hose outside of its specified temperature range can cause the inner tube and outer cover materials to degrade prematurely. High heat can make the rubber brittle, while cold temperatures can cause it to stiffen and crack.

- Improper Installation: Twisting the hose during installation or bending it beyond its minimum bend radius creates localized stress points. These weakened areas are highly susceptible to failure under pressure, leading to a burst.

- Fluid Incompatibility: Using a hydraulic fluid that is not compatible with the hose’s inner tube material can cause the rubber to swell, harden, or corrode from the inside. This internal degradation weakens the hose, leading to a burst.

How to Fix a Busted Hydraulic Hose?

Repairing a busted hydraulic hose requires a methodical approach to ensure the system is restored safely and effectively. This process involves more than just replacing the hose; it’s about proper preparation, component selection, and meticulous assembly to prevent future failures and maintain system integrity.

Step 1: Preparation and Safety

First, de-pressurize the hydraulic system completely to prevent serious injury from high-pressure fluid. Secure the equipment and use appropriate personal protective equipment, including safety glasses and gloves. Clean the area around the hydraulic hose to remove dirt, which could contaminate the system.

Next, carefully drain any residual fluid from the damaged hose into a suitable container to avoid spills. This ensures the workspace is clean and safe before you begin the replacement. Properly dispose of the old hose and the collected fluid according to environmental regulations.

Step 2: Hydraulic Hose and Fittings Selection

Measure the length and diameter of the old hose to select a suitable replacement. Match the hose’s pressure rating, material, and temperature range to the original specifications to ensure compatibility with your system’s operational demands. Choosing the wrong hose can lead to a quick re-failure.

Select new fittings that match the original hose ends, considering the thread type and size. Ensure the fittings are designed for the chosen hose type and pressure rating. A mismatch between the hose and fittings can cause leaks or blowouts.

Step 3: Assembly and Crimping

Cut the new hose to the correct length and prepare the ends for fitting installation. Apply a clean, light lubricant to the fitting threads to facilitate a smooth, secure connection. This step ensures a tight seal and prevents damage to the fitting or hose.

Use a professional hydraulic hose crimping machine to securely attach the new fittings to the hose ends. Follow the manufacturer’s specific crimp diameter settings to achieve a perfect, long-lasting connection. An improperly crimped hose is a major cause of future failure.

Step 4: Installation and Testing

Install the new hose, ensuring it is properly routed to avoid twists or sharp bends. Confirm it does not rub against other components, which could cause abrasion. A correctly routed hose will have a much longer service life and perform more reliably.

Finally, re-pressurize the hydraulic system slowly and carefully. Check the new hose and its fittings for any leaks or signs of weeping. Monitor the system under normal operating conditions to confirm it is functioning properly and that the repair is a success.

What is the Burst Pressure for a Hydraulic Hose?

The burst pressure of a hydraulic hose is the maximum internal pressure it can withstand before it physically ruptures or fails catastrophically. This is a critical safety specification that is much higher than the hose’s working pressure—the pressure it’s designed to handle during normal operation. Manufacturers typically design hoses with a safety factor, meaning the burst pressure is at least 3 to 4 times greater than the working pressure.

- Safety Margin: The high burst pressure provides a vital safety buffer to accommodate sudden, unexpected pressure surges or spikes that can occur in a hydraulic system, preventing catastrophic failures and injuries.

- Quality Indicator: Burst pressure is determined through rigorous testing, where a hose is subjected to increasing pressure until it fails. This test validates the hose’s design and material integrity, serving as a key indicator of its overall quality.

- System Integrity: Burst pressure ensures that the hose is the strongest component in the hydraulic system from a pressure standpoint. If a failure occurs due to over-pressurization, it’s more likely to happen at a weak point like a valve or fitting, which is easier to contain and repair.

- Application Specific: Burst pressure ratings vary widely depending on the hose’s construction, diameter, and the specific application it’s designed for. This is why it’s crucial to select a hose with a burst pressure rating appropriate for your system’s maximum potential pressure.

This video is relevant because it demonstrates a test of a hydraulic hose sleeve’s ability to protect against dangerous oil injection in a high-pressure hose failure.

How to Calculate Burst Pressure of Hydraulic Hose?

Calculating the burst pressure of a hose is crucial for ensuring system safety and reliability. While our hydraulic hose manufacturers provide a burst pressure rating, understanding the underlying factors and the process helps in selecting the correct hose and maintaining a safe operating environment.

Step 1: Identify Key Specifications

First, you need to identify the hose’s critical specifications from the manufacturer’s data sheet. These include the hose’s maximum recommended working pressure, its inner diameter (ID), and the material of both the inner tube and the reinforcement. These details are the basis for all calculations.

Next, you need to know the Safety Factor. This is a crucial number that provides a margin of safety and is typically a ratio like 4:1, meaning the burst pressure is four times the working pressure. This information is key to ensuring the hose can handle unexpected pressure surges.

Step 2: Use the Formula

The general formula for calculating burst pressure is to multiply the maximum working pressure by the safety factor. This simple calculation gives you the rated burst pressure of the hose. For example, a hose with a working pressure of 5,000 PSI and a 4:1 safety factor has a burst pressure of 20,000 PSI.

It’s important to note that this is a theoretical calculation and should always be verified against the manufacturer’s specifications. The actual burst pressure is determined through destructive testing, where a sample hose is pressurized until it fails. This test confirms the product’s integrity.

Step 3: Consider Environmental Factors

Temperature plays a significant role in a hose’s pressure capacity. High temperatures can weaken the hose materials, potentially lowering its actual burst pressure. Always select a hose with a working temperature range that exceeds your application’s requirements.

Exposure to chemicals, UV rays, or abrasion can also degrade the hose material over time, which will reduce its burst pressure. Regular inspection and proper protection are essential to ensure the hose maintains its rated burst pressure throughout its service life.

Hydraulic Hose Burst Protection

Protecting against hydraulic hose bursts is a critical safety measure in any industrial setting. While using a high-quality hose with the correct pressure rating is the first step, external protection is essential to mitigate the risks of abrasion, impact, and high-temperature exposure. Implementing proactive measures not only extends the lifespan of your hoses but also prevents catastrophic failures that can cause serious injury, equipment damage, and environmental harm.

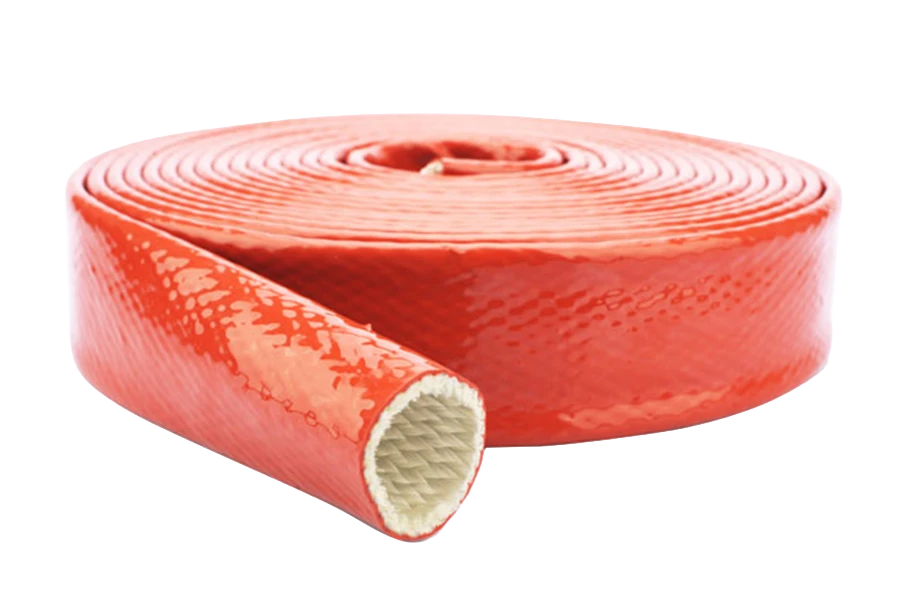

- Protective Sleeves: These are one of the most effective solutions. Made from durable materials like nylon, polypropylene, or fire-retardant fiberglass, sleeves protect hoses from external abrasion, UV damage, and even high heat or fire, preventing premature wear and tear.

- Hose Guards: Spiral wrap hose guards, often made from plastic, are a low-cost and highly effective way to protect hoses from rubbing against each other or sharp edges. Their flexible design allows for easy installation and excellent abrasion resistance.

- Bending Restrictors: These are used to prevent a hose from bending beyond its minimum bend radius. Excessive bending can weaken the hose’s reinforcement layers, leading to a burst. Bending restrictors help maintain the hose’s integrity during operation.

- Routing and Clamping: Proper hose routing is fundamental to burst protection. Hoses should be routed to avoid contact with moving parts and heat sources. Using clamps and brackets secures the hoses in place, preventing them from shifting and causing abrasion.

- Whip Socks: In high-pressure applications, a whip sock is a safety device that is installed over the hose assembly. If the hose bursts or disconnects, the sock will contain the whipping hose, preventing it from lashing out and causing severe injury.

Conclusion

By understanding and addressing the main causes of hydraulic hose bursts, you can significantly enhance the safety, reliability, and efficiency of your hydraulic systems. Proactive measures—such as regular inspections, proper installation, and using the right components—are far more cost-effective than dealing with the aftermath of a catastrophic failure. Prioritizing hose health protects your equipment, minimizes downtime, and ensures the well-being of your personnel.

For a reliable solution that supports your preventive maintenance efforts, consider sourcing your hydraulic hoses from a trusted wholesale provider. Our hydraulic hoses are manufactured to the highest standards, engineered to withstand extreme pressures and environments, and backed by a commitment to quality. This ensures you get a durable product that reduces the risk of premature failure and keeps your operations running smoothly.

Ready to secure a long-term supply of hydraulic hoses? Look no further than Kingdaflex. As a leading manufacturer and wholesaler, we offer a comprehensive range of hydraulic hoses designed for every application. Our products are competitively priced and meet strict international standards, providing you with the peace of mind that comes from using a dependable and safe component. Partner with Kingdaflex today.