Crafting reliable hydraulic hose assemblies hinges on precision, and at the heart of that precision lies the hydraulic hose chop saw. Forget the struggles of uneven, frayed cuts that compromise performance and lead to costly reworks. This specialized tool isn’t just an accessory; it’s a fundamental investment for anyone serious about producing high-quality, perfectly sized hydraulic hoses

Achieving the exact hose length is critical for optimal system function, preventing unnecessary strain, kinking, or excessive slack. A dedicated hydraulic hose chop saw ensures clean, straight cuts every single time, minimizing material waste and significantly boosting efficiency in your fabrication process. It’s the difference between a good assembly and a flawless one.

What is a Hydraulic Hose Chop Saw?

A hydraulic hose chop saw is a specialized power tool meticulously designed for cutting hydraulic hoses with precision and efficiency. Unlike standard saws, these machines feature robust blades, often abrasive or circular saw types, and powerful motors capable of cleanly severing reinforced hydraulic hoses, which contain multiple layers of wire braiding or textile reinforcement.

Their design prioritizes safety and accuracy, providing stable clamping mechanisms to hold the hose firmly in place during the cutting process, minimizing fraying and ensuring straight, perpendicular cuts essential for proper fitting crimping and optimal hose assembly performance.

Key features and benefits of a Hydraulic Hose Chop Saw:

- Precision Cutting: Delivers clean, straight cuts crucial for proper fitting installation and preventing leakage.

- Safety Features: Often includes blade guards, safety switches, and secure clamping systems to protect the operator.

- Efficiency: Significantly speeds up the hose fabrication process compared to manual cutting methods.

- Durability: Built to withstand the demands of cutting tough, reinforced hydraulic hoses repeatedly.

- Reduced Fraying: Minimizes fraying of hose reinforcement layers, which can compromise the integrity of the crimp.

- Versatility: Capable of cutting various types and sizes of hydraulic hoses.

How Does a Hydraulic Hose Chop Saw Work?

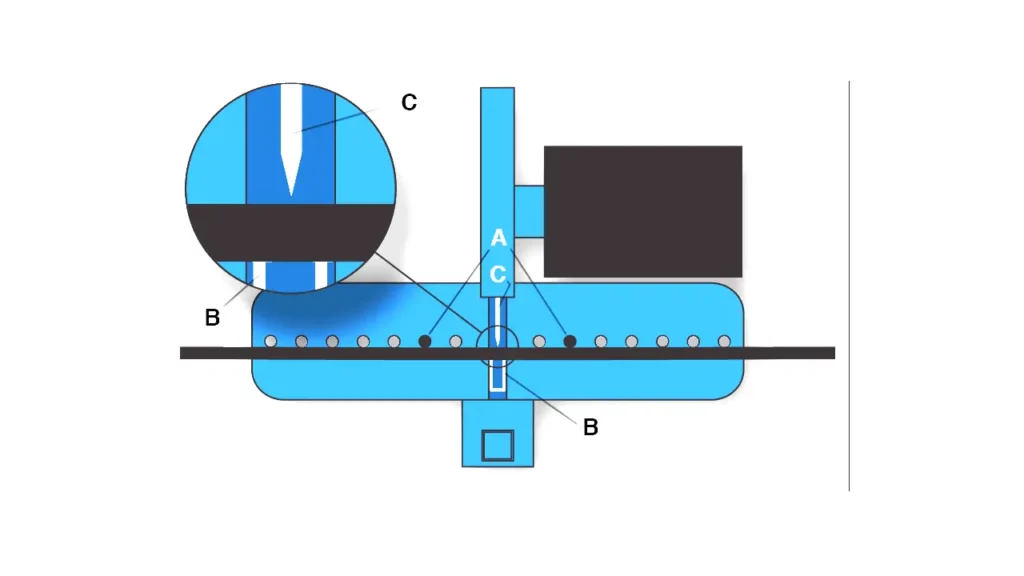

As illustrated in the diagram, a hydraulic hose cutting saw operates by securely clamping the hose and utilizing a powerful rotating blade to achieve a clean, precise cut. The hose (represented horizontally) is positioned within a sturdy base (A) and held firmly in place by a clamping mechanism (B).

A motorized cutting head, containing a specialized blade (C), is then brought down onto the hose. The blade, designed to efficiently cut through the reinforced layers of hydraulic hose without excessive fraying, severs the material cleanly, ensuring a smooth and accurate end for subsequent fitting attachment.

Here’s how it generally works:

- Clamping Mechanism (B): The hose is inserted into a vice or clamping system that securely holds it immobile during the cutting process. This ensures stability and prevents the hose from shifting, which is critical for a straight cut.

- Cutting Blade (C): A high-speed rotating blade, typically made of hardened steel or an abrasive material, is powered by a motor. This blade is specifically designed to cut through the multiple layers of rubber, textile, and wire reinforcement found in hydraulic hoses. The zoomed-in section shows the blade (C) making contact with the hose.

- Controlled Descent: The cutting head, with the spinning blade, is lowered onto the clamped hose, either manually or via a controlled mechanism. This controlled descent ensures a smooth, even cut.

- Motor (A): The motor provides the necessary power to rotate the cutting blade at high speeds, enabling it to efficiently sever the tough materials of the hydraulic hose. (A represents the overall structure housing the motor and blade mechanism).

How to Cut Hydraulic Hoses with Chop Saw

Properly cutting hydraulic hoses with a chop saw is crucial for creating reliable, leak-free assemblies. This guide outlines the essential steps to ensure precision and safety, extending the life of your hydraulic systems and preventing costly failures.

Following these steps meticulously will not only achieve perfect hose lengths but also minimize fraying and prepare the hose optimally for crimping. Accuracy at this stage is fundamental to the overall integrity of your hydraulic connections and fluid transfer.

Step 1: Prepare the Work Area and Gather Tools

Before starting, ensure your work area is clean, well-lit, and free from obstructions. Lay out all necessary tools, including the hydraulic hose chop saw, a measuring tape, a marking tool, and appropriate safety gear like gloves and eye protection.

Verify the chop saw’s blade is sharp and suitable for cutting reinforced hydraulic hoses. A dull or incorrect blade can lead to frayed ends and an imprecise cut, compromising the integrity of the hose assembly.

Step 2: Measure and Mark the Hose

Accurately measure the required length of the hydraulic hose using a reliable measuring tape. It’s crucial to measure from the end of the hose, taking into account any fittings that will be crimped on later.

Once measured, clearly mark the precise cutting point on the hose. A visible marker will ensure accuracy when positioning the hose in the chop saw, preventing errors that could lead to wasted material or an improperly sized assembly.

Step 3: Secure the Hose in the Chop Saw

Carefully open the chop saw’s vise or clamping mechanism and position the marked hose securely. Ensure the mark aligns perfectly with the cutting path of the blade. The hose must be held firmly to prevent movement during cutting.

A stable and tight clamp is essential for a clean, straight cut. Any movement of the hose during the cutting process can result in an uneven, angled, or frayed end, which can negatively impact the crimping process and hose performance.

Step 4: Make the Cut

With the hose securely clamped and safety gear in place, slowly engage the chop saw. Allow the blade to reach its full operating speed before making contact with the hose to ensure a smooth, clean cut. Apply steady, even pressure.

Avoid forcing the blade through the hose, as this can lead to excessive heat, blade wear, and a rough cut. Once the cut is complete, allow the blade to stop rotating fully before carefully releasing the hose from the clamp.

Tips for Cutting Hydraulic Hoses

Achieving clean and accurate cuts on hydraulic hoses is paramount for reliable system performance and longevity. Beyond simply having the right tools, employing proper techniques and adhering to best practices can significantly enhance the quality of your hose assemblies, prevent material waste, and ensure operational safety.

- Use the Right Hydraulic Hose Chop Saw Blade: Always match the blade type to the hose’s construction. For wire-reinforced hoses, specialized steel blades (often scalloped or serrated) are far superior to abrasive wheels, which can cause fraying and contamination.

- Ensure Blade Sharpness: A sharp blade is crucial for clean cuts. Dull blades lead to frayed ends, excessive heat buildup, and a more difficult cutting process. Replace or sharpen blades regularly.

- Secure the Hose Firmly: Utilize the chop saw’s clamping mechanism to hold the hose absolutely still and square to the blade. Any movement will result in an uneven or angled cut.

- Measure Accurately: Double-check your measurements before marking the cut point. Precision at this stage prevents wasted material and ensures the hose fits perfectly in the assembly.

- Minimize Fraying: For wire-braided hoses, a “cold cut” (using a sharp, non-abrasive blade) is preferred as it minimizes fraying of the wire reinforcement, which is critical for proper fitting crimping.

- Clean After Cutting: Immediately after cutting, clean the inside and outside of the hose end to remove any debris, rubber particles, or wire fragments. Contaminants can cause blockages or damage within the hydraulic system.

- Wear PPE: Always wear appropriate personal protective equipment, including safety glasses and gloves, to protect against flying debris and sharp edges.

Conclusion

In conclusion, the hydraulic hose chop saw is more than just a piece of equipment; it’s a cornerstone for achieving excellence in hydraulic hose fabrication. Its ability to deliver precise, clean cuts consistently is invaluable, ensuring that every hose assembly meets the highest standards of reliability and performance. Investing in a quality chop saw directly translates to reduced material waste, increased operational efficiency, and ultimately, a superior end product that you can trust.

Perfect hydraulic hose lengths are non-negotiable for system integrity and longevity. By utilizing a specialized chop saw, you eliminate guesswork and mitigate common issues like premature wear or component failure caused by improperly sized hoses. This precision empowers you to build robust hydraulic systems that operate smoothly and efficiently, minimizing downtime and maximizing productivity in any application.

When sourcing components for your projects, remember that Kingdaflex offers a comprehensive range of wholesale hydraulic hoses to complement your precision cutting. Pair your expertly cut hoses with our high-quality materials for assemblies that stand the test of time. Reach out to Kingdaflex today to get wholesale hydraulic hoses for your project and complete your perfect hydraulic solutions.