In the world of machinery and heavy equipment, hydraulic systems are the unsung heroes. These systems rely on hydraulic hoses to transmit power efficiently, making them a critical component in various industries.

In this article, we’ll explore the world of hydraulic hose design, shedding light on their importance, components, types, and the factors to consider when selecting the right one for your application.

Introduction to Hydraulic Hose Design

In the world of machinery and heavy equipment, the smooth operation of hydraulic systems is a critical component. These systems rely on hydraulic hoses, which serve as vital conduits for transmitting hydraulic fluid. Hydraulic hose design is a fascinating field that involves crafting hoses capable of withstanding high pressures, ensuring efficient power transmission, and guaranteeing the reliability of a wide range of industrial applications.

Hydraulic hoses are the unsung heroes behind the scenes of many industries, from construction and agriculture to manufacturing and aerospace. They are the arteries of hydraulic systems, responsible for carrying hydraulic fluid under immense pressure, enabling the precise control of heavy machinery and various mechanical operations.

At its core, hydraulic hose design is a delicate balance of science and engineering. It involves understanding the properties of materials, the physics of fluid dynamics, and the mechanical forces at play in a system. Designing a hydraulic hose that can perform reliably and withstand the rigors of demanding applications is no small feat.

This article will take you on a journey through the intricacies of hydraulic hose design. We will explore the importance of these hoses, dissect their key components, discuss the various types available, and delve into the factors one should consider when selecting the right hose for a specific application.

From the inner tube that carries the hydraulic fluid to the outer cover that protects the hose, every element of the hydraulic hose design serves a purpose. Understanding these components is essential for anyone working with hydraulic systems or machinery that relies on them.

Furthermore, we will discuss the advancements in hydraulic hose technology, the role of hydraulic hoses in different industries, common problems they may encounter, and how to troubleshoot these issues. Safety precautions and the future of hydraulic hose design will also be explored.

So, fasten your seatbelt and get ready to embark on a journey through the world of hydraulic hose design, where innovation and precision come together to ensure the reliable transfer of power in the machinery that drives our modern world.

Importance of Hydraulic Hoses

Let’s delve deeper into the importance of hydraulic hoses in various industries and applications.

The Vital Role of Hydraulic Hoses

Hydraulic hoses are the unsung heroes of many industrial sectors, playing a pivotal role in ensuring the smooth and efficient operation of heavy machinery. Their importance can be summarized in several key points:

Power Transmission:

Hydraulic hoses are the conduits through which hydraulic fluid, typically oil, flows. This fluid transmits power from one component of a hydraulic system to another. This power transfer is essential for the functioning of various equipment, from construction machinery like excavators and bulldozers to manufacturing processes and even the braking systems in automobiles.

Precision and Control:

Hydraulic systems are known for their ability to provide precise control and movement. This precision is vital in industries where even the slightest error can lead to costly mistakes or accidents. Hydraulic hoses allow for fine-tuned control, making them indispensable in applications where accuracy and reliability are paramount.

Efficiency:

Hydraulic systems, driven by hydraulic hoses, are highly efficient in converting mechanical power into hydraulic power and vice versa. This efficiency results in reduced energy consumption, making hydraulic systems a cost-effective choice for industries looking to minimize operational costs.

Versatility:

Hydraulic hoses are used in a wide range of industries, from agriculture and construction to aerospace and manufacturing. Their adaptability to diverse environments and applications demonstrates their versatility.

Durability:

Hydraulic hoses are designed to withstand extreme conditions, such as high pressures and temperature variations. This durability ensures that they can perform reliably in challenging environments, even when exposed to chemicals, abrasion, and other hazards.

Reduction in Mechanical Linkages:

Hydraulic systems, enabled by hydraulic hoses, reduce the need for complex mechanical linkages. This simplifies the design of machinery, making it more compact and lightweight.

Safety:

The reliability and performance of hydraulic hoses are critical for ensuring the safety of both equipment and personnel. Any failure in a hydraulic hose can lead to accidents, environmental damage, and costly downtime. Therefore, proper design, installation, and maintenance of hydraulic hoses are crucial for preventing mishaps.

Environmental Benefits:

Hydraulic systems are often considered environmentally friendly due to their efficiency. They can help reduce emissions and fuel consumption in various applications, contributing to a greener and more sustainable future.

The hydraulic hoses are the lifelines of hydraulic systems, underpinning their efficiency, precision, and reliability. Their importance extends to various industries, where they contribute to enhanced productivity, reduced operational costs, and increased safety. As technology advances, hydraulic hose design continues to evolve, further enhancing their role in powering the machinery that drives our world.

Key Components of Hydraulic Hoses

To understand hydraulic hose design, it’s essential to break down their key components.

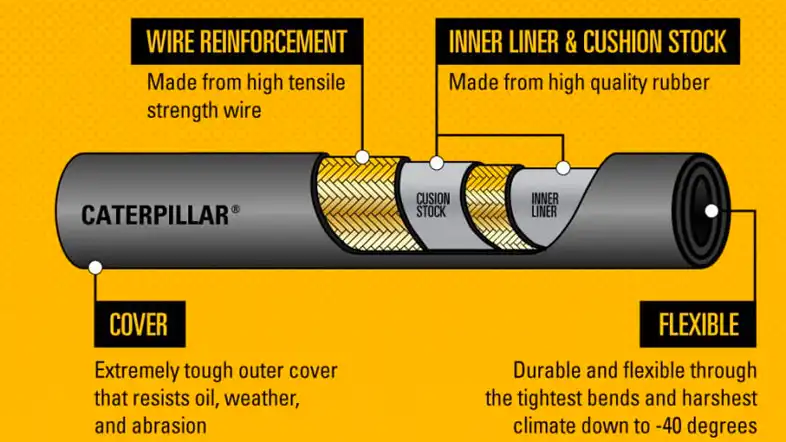

Inner Tube

The inner tube of a hydraulic hose is the conduit through which hydraulic fluid flows. It must be compatible with the type of fluid used in the system to prevent chemical reactions or contamination.

Reinforcement Layer

Reinforcement layers provide structural integrity to the hose, ensuring it can withstand high pressures. Common reinforcement materials include steel wire or textile braid.

Outer Cover

The outer cover protects the hose from environmental factors like abrasion, UV exposure, and chemicals. It also adds an additional layer of reinforcement.

Types of Hydraulic Hoses

Hydraulic hoses come in various types, each designed for specific applications.

Hydraulic Hose Classifications

Hydraulic hoses are classified by the SAE (Society of Automotive Engineers) based on their construction and performance. Some common classifications include R1, R2, R3, and R4 hoses.

Teflon Hoses

Teflon hoses are known for their excellent chemical resistance and are often used in applications involving aggressive fluids.

Multi-Spiral Hoses

Multi-spiral hoses are designed to handle extreme pressures, making them suitable for heavy-duty applications.

Selecting the Right Hydraulic Hose

Choosing the right hydraulic hose is crucial for the efficiency and safety of your hydraulic system.

Factors to Consider When Choosing a Hydraulic Hose

Temperature Range

Consider the temperature at which the hose will operate. Some hoses are designed to withstand high temperatures, while others excel in cold environments.

Pressure Rating

The hose’s pressure rating must match the system’s requirements to prevent accidents and system failures.

Fluid Compatibility

Ensure that the hose is compatible with the hydraulic fluid used in the system to prevent degradation and contamination.

Hose Size

Select the appropriate hose size to ensure efficient fluid flow and minimal pressure drop.

Proper Installation and Maintenance

Proper installation and maintenance are essential for the longevity and reliability of hydraulic hoses.

Installation Guidelines

Follow manufacturer guidelines for hose assembly, routing, and securing to prevent kinks, abrasion, and excessive bending.

Maintenance Best Practices

Regularly inspect hoses for wear, abrasion, or leaks. Replace damaged hoses promptly to avoid costly downtime.

Advancements in Hydraulic Hose Technology

The field of hydraulic hose design is continually evolving, with advancements in materials and construction techniques leading to more efficient and durable hoses.

The Role of Hydraulic Hoses in Various Industries

Hydraulic hoses are integral in various industries, including construction, agriculture, aerospace, and automotive, ensuring that heavy machinery operates seamlessly.

Common Hydraulic Hose Problems

Despite their durability, hydraulic hoses can encounter issues such as leaks, abrasion, and kinking.

Troubleshooting Hydraulic Hose Issues

Understanding common problems and troubleshooting techniques is essential for preventing system failures.

Safety Precautions When Working with Hydraulic Hoses

Working with hydraulic hoses requires safety precautions to protect personnel and equipment.

The Future of Hydraulic Hose Design

As technology advances, hydraulic hoses will continue to improve, offering even higher performance, durability, and safety.

Conclusion

Hydraulic hose design is a crucial aspect of hydraulic systems, impacting their efficiency and safety. Choosing the right hose and ensuring proper installation and maintenance are essential for reliable operation.

As industries evolve, hydraulic hose design will continue to advance, contributing to safer and more efficient machinery.

FAQs

Are hydraulic hoses and pneumatic hoses the same?

No, hydraulic hoses are designed to handle high-pressure hydraulic fluid, while pneumatic hoses are used for lower-pressure air or gas applications.

Can hydraulic hoses be repaired when damaged?

It’s generally recommended to replace damaged hydraulic hoses rather than attempting repairs to ensure safety and reliability.

What’s the typical lifespan of a hydraulic hose?

The lifespan varies depending on usage and maintenance, but properly maintained hoses can last for several years.

What’s the best way to store hydraulic hoses when not in use?

Hoses should be stored away from direct sunlight, chemicals, and extreme temperatures to prolong their lifespan.

What safety gear should I wear when working with hydraulic hoses?

Safety glasses, gloves, and appropriate clothing should be worn to protect against hydraulic fluid leaks and accidents.