Hydraulic hose fitting size chart is a valuable tool for anyone working with hydraulic systems. It helps ensure you select the correct fitting for your specific hose and application.

Hydraulic hose fitting sizes are designated by two main factors: the inner diameter (ID) of the hose they fit and the fitting type.

This refers to the opening size of the hose that the fitting is designed to connect with. It’s typically indicated in inches (e.g., 1/4″, 3/8″, 1/2″) or millimeters (e.g., 6mm, 10mm, 12mm). You’ll find this information in hose sizing charts or directly on the hose itself.

There are various fitting styles, each suited for specific applications and offering advantages in terms of sealing, installation, or working pressure.

These JIC hydraulic hose fittings use a 37-degree cone seal for a tight connection and are popular for high-pressure applications.

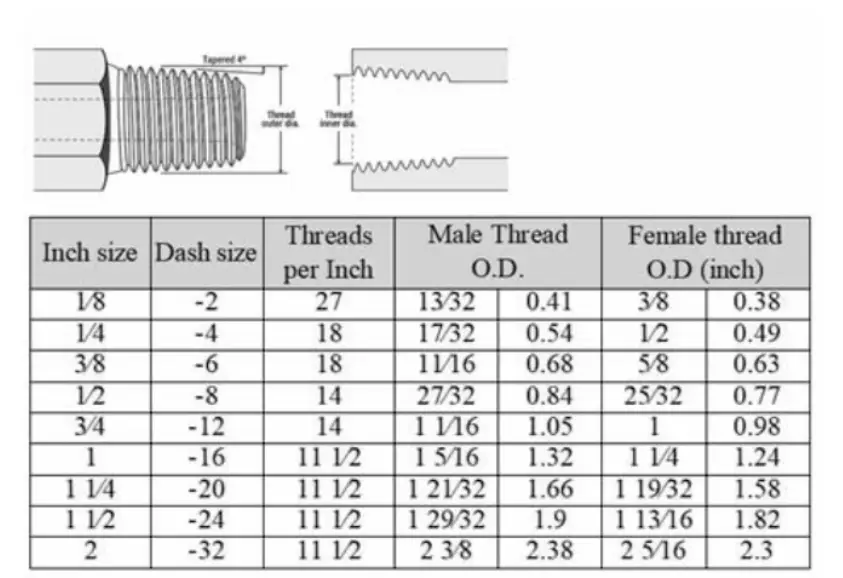

These NPT hydraulic hose fittings have tapered threads for sealing against a matching tapered surface. They are widely used and available in various sizes.

These o-ring hydraulic hose fittings create a seal with an O-ring, offering good sealing performance and reusability.

A BSPP fitting, or British Standard Pipe Parallel fitting, is a type of pipe fitting used to create secure connections in plumbing systems.

A hydraulic hose fitting size chart is a helpful tool that lists these two factors (ID and fitting type) along with additional specifications like:

Important Tips:

Here’s a simplified table representing a typical hydraulic hose fitting size chart:

| Hose Size (ID) | Fitting Type | Thread Size (Example) | Material (Example) | Pressure Rating (Example) |

|---|---|---|---|---|

| 1/4″ | JIC | 1/4″ NPTF | Steel | 3,000 PSI |

| 3/8″ | NPT | 3/8″ BSPP | Brass | 2,500 PSI |

| 1/2″ | SAE | 1/2″ ORFS | Stainless Steel | 4,000 PSI |

| 3/4″ | Flange | – | – | – |

Note:

Remember, for accurate information, consult the size chart provided by the manufacturer of the specific hydraulic hose fittings you’re considering.

Hydraulic hose fittings are employed in a wide range of applications that rely on fluid power transmission.

To measure hydraulic hose fittings, you need calipers to find:

Measure the Inner Diameter (ID):

Measure the Thread Size (Optional, but recommended for precise fit):

We are a leading manufacturer of hydraulic hose fittings. As a one-stop factory for your hydraulic hose needs, we offer a comprehensive selection of hydraulic hose fittings in various sizes and types to ensure compatibility with your specific application. Don’t hesitate to contact us today! Our hydraulics experts are happy to assist you in choosing the most suitable fittings for your project.