When it comes to fluid power systems, hoses play a vital role in transporting fluids and energy. Two commonly used types of hoses are hydraulic hoses and pneumatic hoses.

Although they may seem similar, they are designed for different purposes and have distinct differences. This article will explore the differences between hydraulic hoses and pneumatic hoses, and which one you should choose for your specific needs.

What Are Hydraulic Hoses?

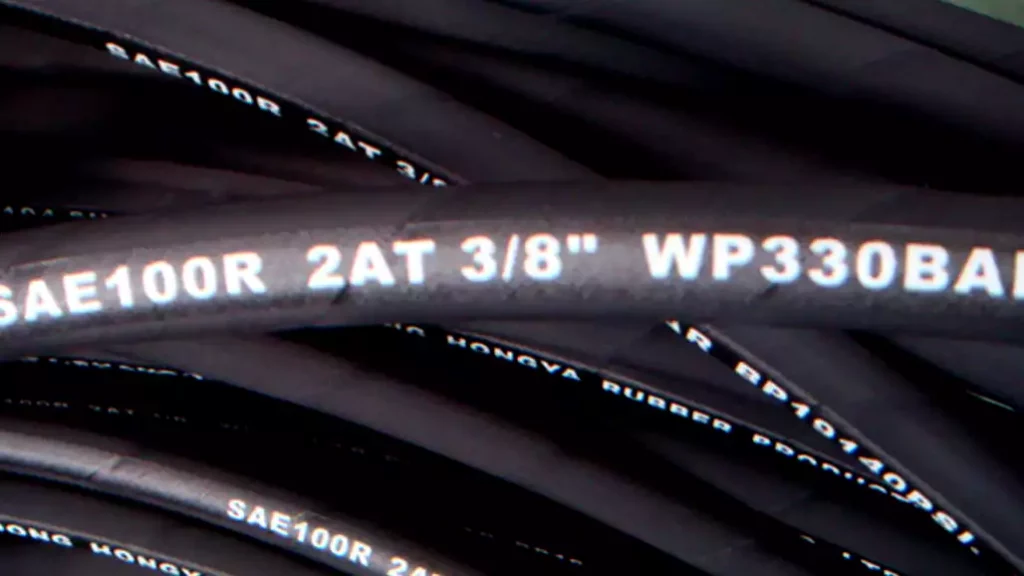

Hydraulic hoses are used to transport fluids, such as oil and water, under high pressure. They are used in various applications, such as in construction equipment, industrial machinery, and hydraulic systems in cars. Hydraulic hoses are made up of three layers: the inner tube, the reinforcement layer, and the outer cover. The inner tube is made of a synthetic rubber material that is resistant to the fluid being transported. The reinforcement layer provides strength and durability to the hose and is made of steel wire or synthetic fibers. The outer cover protects the hose from abrasion, weather, and chemicals.

What Are Pneumatic Hoses?

Pneumatic hoses are used to transport compressed air, gases, and other non-corrosive materials. They are commonly used in pneumatic systems, such as in industrial automation, robotics, and air brakes in vehicles. Pneumatic hoses are similar to hydraulic hoses in their construction, with the main difference being their intended use. Pneumatic hoses are designed to handle lower pressures than hydraulic hoses and are typically made of PVC, rubber, or polyurethane.

Differences Between Hydraulic Hoses and Pneumatic Hoses

Fluid Type:

Hydraulic hoses are specifically designed to transport liquids, such as hydraulic oil or water-based fluids, while pneumatic hoses are designed to transport gases, such as compressed air or nitrogen. This difference is due to the properties of the fluids involved – liquids are typically denser and less compressible than gases, and therefore require different types of hoses to transport them.

Pressure Range:

Hydraulic systems typically operate at much higher pressures than pneumatic systems. For example, a typical hydraulic system may operate at pressures of 3,000 to 5,000 psi, while a typical pneumatic system may operate at pressures of 100 to 200 psi. As a result, hydraulic hoses need to be able to handle much higher pressures than pneumatic hoses.

Hose Construction:

Hydraulic hoses are typically constructed with multiple layers of reinforcement, such as steel wire or synthetic fibers, to handle the high pressures involved. The inner layer of the hose is typically made from a synthetic rubber or thermoplastic material that is compatible with the fluid being transported. Pneumatic hoses, on the other hand, are typically constructed with a single layer of reinforcement, such as braided nylon or synthetic fibers.

Hose Size:

Hydraulic hoses are typically larger in diameter than pneumatic hoses, because they need to handle more fluid flow. A typical hydraulic hose may have an inner diameter of 1/4 inch to 2 inches, while a typical pneumatic hose may have an inner diameter of 1/8 inch to 1 inch.

Related: What Hydraulic Hose Sizes Suit Your Hydraulic System? [Guide to Hose Sizing]

End Fittings:

The end fittings used on hydraulic hoses and pneumatic hoses are different. Hydraulic hoses typically use crimped or swaged fittings, which are permanently attached to the hose using a special tool. Pneumatic hoses often use push-on fittings, which can be easily attached or removed by hand. The Complete Guide About Hydraulic Hose Fittings

Fluid Compatibility:

Hydraulic hoses are designed to be compatible with the specific fluid they will be transporting. For example, a hydraulic hose designed for use with hydraulic oil may not be compatible with water-based fluids.

Pneumatic hoses typically have a broader range of fluid compatibility, because they are designed to transport gases that are less reactive than liquids. However, it’s still important to choose a pneumatic hose that is compatible with the specific gas being transported, to ensure safety and optimal performance.

Which One Should You Choose?

When choosing between hydraulic hoses and pneumatic hoses, you should consider the application and the pressure requirements. If you need to transport fluids under high pressure, such as in heavy-duty machinery, hydraulic hoses are the way to go. Click How to Choose A Hydraulic Hose? [STAMPED Hose Selection Guide] to more about hydraulic hose selection.

However, if you need to transport compressed air or gases at lower pressures, such as in industrial automation, pneumatic hoses are the better choice.

It’s important to note that using the wrong type of hose can result in safety hazards, such as hose failure and fluid leakage. Always consult with a professional to ensure you are using the appropriate hose for your specific needs.

FAQs

- Can hydraulic hoses be used for pneumatic systems?

Hydraulic hoses are not recommended for use in pneumatic systems due to their higher pressure ratings and stronger reinforcement layer. Using hydraulic hoses for pneumatic systems can result in safety hazards, such as hose failure and air leakage.

- Can pneumatic hoses be used for hydraulic systems?

No, pneumatic hoses are not designed to handle the high-pressure fluid transport required in hydraulic systems. Using pneumatic hoses for hydraulic systems can result in safety hazards, such as hose failure and fluid leakage.

- What is the lifespan of hydraulic and pneumatic hoses?

The lifespan of hydraulic and pneumatic hoses depends on various factors, such as the quality of the materials used, the application, and maintenance. On average, hydraulic hoses have a lifespan of 5-7 years, while pneumatic hoses have a lifespan of 3-5 years.

- Can hoses be repaired if they are damaged?

Yes, hoses can be repaired if they are damaged, depending on the extent of the damage. It’s important to have damaged hoses repaired by a professional to ensure safety and proper function.

- Are there any safety precautions to take when using hoses?

Yes, it’s important to take safety precautions when using hoses, such as ensuring proper installation, avoiding sharp bends, and regularly inspecting the hoses for damage. Proper use and maintenance of hoses can prevent safety hazards, such as hose failure and fluid leakage.

Conclusion

In conclusion, hydraulic hoses and pneumatic hoses are two different types of hoses used for fluid power systems. Hydraulic hoses are designed for high-pressure fluid transport, while pneumatic hoses are designed for low-pressure air transport. When choosing between the two, consider the application and pressure requirements to ensure you are using the appropriate hose for your needs.