Explore high-performance hydraulic hoses at Kingdaflex. Manufacturing SAE & DIN standards, our durable solutions power diverse sectors including agriculture, industrial machinery, oil & gas, and construction.

Ensure reliable fluid power transmission for any mobile or stationary equipment—contact us for a competitive quote today!

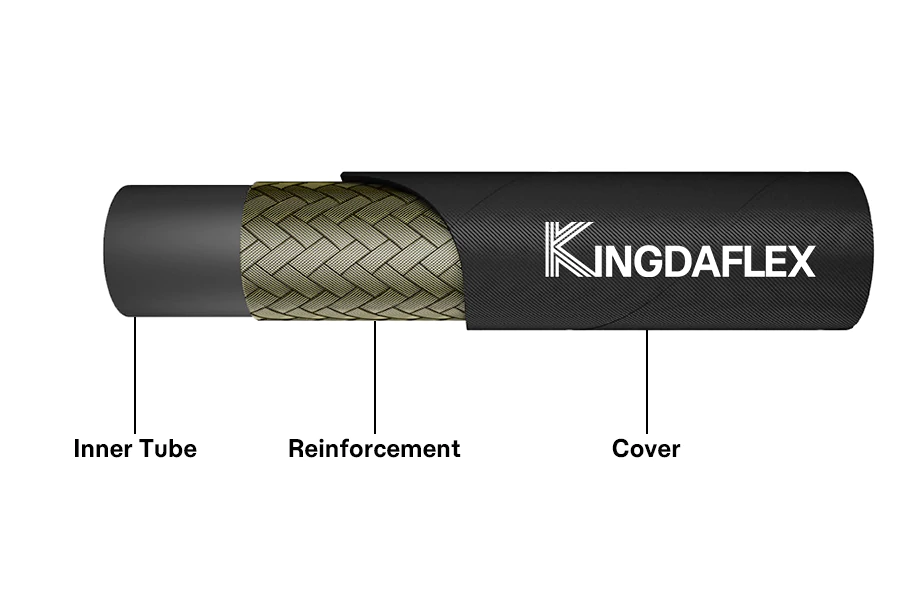

Inner Tube: Oil-resistant synthetic rubber (NBR/Synthetic blend) ensuring compatibility with petroleum, water, and glycol-based fluids.

Reinforcement: High-tensile steel wire (1-2 braids or 4-6 spirals) or durable textile cords to withstand extreme pressure and vibration.

Cover Options:

Engineered for the most grueling environments, our ultra-high-pressure spiral hoses resist severe abrasion and rock impact. They ensure critical safety and minimize costly downtime for excavators, drill rigs, and underground mining equipment.

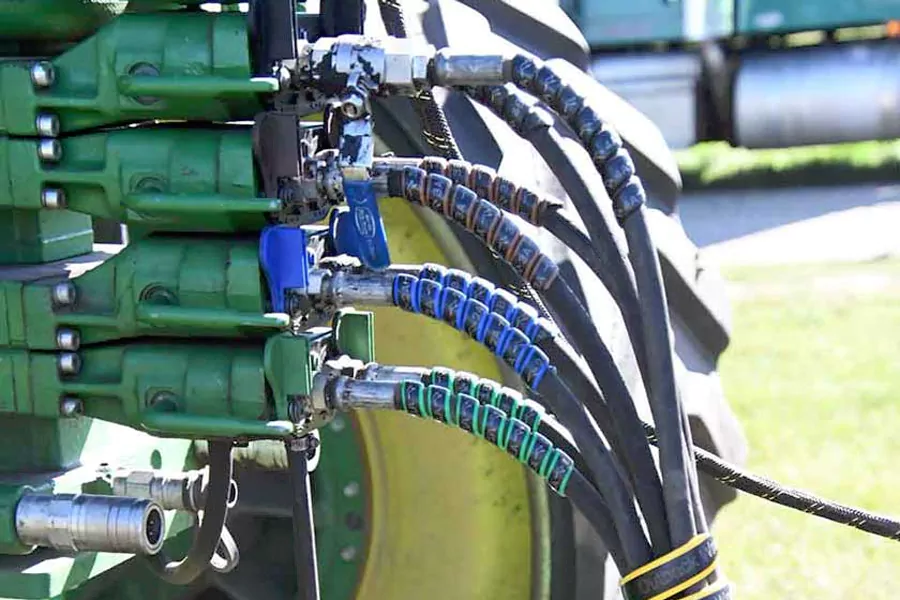

Delivering robust power to heavy earthmoving machinery, our hoses feature superior impulse resistance and tough outer covers. They easily handle the vibration and pressure surges, common in cranes, loaders, and concrete pumping operations.

Tailored for stationary automation systems, our precision hoses provide stable fluid transmission for injection molding and hydraulic presses. They offer leak-free performance and long-term reliability for continuous, high-cycle manufacturing processes.

From raw material testing to final impulse testing, ensuring zero defects.

State-of-the-art braiding and spiraling machines for consistent precision.

Trusted by customers in over 50 countries across Europe, Middle East, and Americas.

Private labeling (OEM), custom lengths, and assembly services available.

The primary difference lies in their reinforcement structure and pressure capabilities. Wire braided hoses (such as SAE 100 R1AT and R2AT) typically feature one or two layers of braided high-tensile steel wire. They offer excellent flexibility and a tighter bend radius, making them ideal for medium-pressure applications and compact routing lines.

In contrast, wire spiral hoses (like EN856 4SP, 4SH, and R13/R15) are reinforced with four or six layers of spiraled steel wire. These are engineered for extremely high-pressure, high-impulse applications, offering superior strength and longevity in grueling environments like mining and heavy excavation.

Selecting the correct hose requires evaluating several critical factors, often referred to as the STAMPED rule.

First, ensure the hose’s working pressure meets or exceeds your system’s maximum pressure.

Second, consider the application environment; for example, mining equipment may need hoses with high abrasion resistance, while agricultural machinery requires superior UV and weather resistance.

You must also verify the fluid compatibility of the inner tube with the oil or liquid being conveyed.

Finally, check the bend radius to avoid kinking.

Kingdaflex offers a wide range of smooth and wrapped cover hoses to match these diverse needs perfectly.

Our hydraulic hoses are constructed using a robust three-layer design to ensure maximum performance.

The inner tube is made from oil-resistant synthetic rubber (typically NBR) to ensure seamless compatibility with petroleum-based hydraulic fluids.

The reinforcement layer consists of high-tensile steel wires or textile cords, arranged in braided or spiral formations, providing the necessary structural integrity to withstand high pressures.

The outer cover is crafted from premium synthetic rubber (such as Neoprene or EPDM blends) designed to resist abrasion, ozone, weathering, and oil, ensuring long service life even in the harshest outdoor or underground conditions.

Yes, Kingdaflex provides comprehensive OEM and ODM services to support your brand identity. We understand that brand recognition is vital for our distributors and equipment manufacturers.

We can customize the hose layline by printing your company logo, part numbers, and specifications directly on the hose surface. Additionally, we offer customization for hose lengths, special packaging, and even specific color requirements to match your market strategy. Whether you need private labeling or a specific hose assembly solution, our manufacturing flexibility allows us to tailor products that align perfectly with your business goals.

Quality is the foundation of our manufacturing process. With over 20 years of industry experience, we strictly adhere to international quality standards.

Our hydraulic hoses are manufactured in accordance with SAE J517 (USA) and DIN EN 853/856 (Europe) specifications, ensuring global compatibility. We implement rigorous quality control measures, including raw material inspection and finished product testing for impulse resistance and burst pressure.

Our commitment to stable quality has earned us ISO management system certifications and the trust of clients in over 50 countries, making us a reliable partner for your fluid power needs.

As a dedicated B2B manufacturer and exporter, we primarily serve wholesalers, distributors, and industrial manufacturers. Our hydraulic hoses are typically supplied in standard rolls of 50 meters or 100 meters, depending on the hose size and type.

While we focus on bulk orders to provide the most competitive wholesale pricing, we remain flexible and open to discussing trial orders to establish a new partnership.

We have extensive experience exporting to Europe, North America, and South America, and we provide professional logistics support to ensure timely and safe delivery to your designated port or warehouse.