Hose products need to handle high temperatures and environmental stress to prevent premature hose failure and safety risks. Thermoplastic hose offers a wide variety of added value over their rubber counterparts.

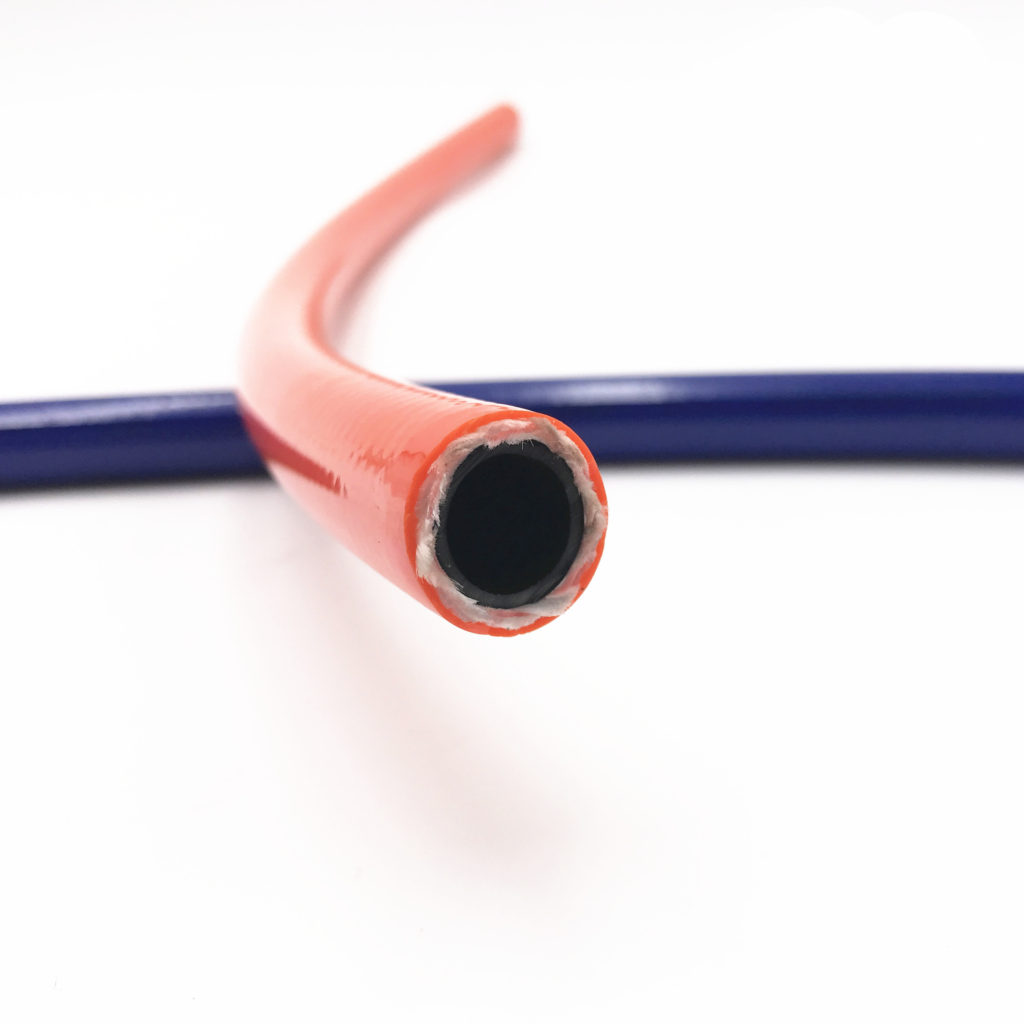

The thermoplastic hydraulic hose is built with a high level of contact strength between the layers of core, braid, and jacket. This contact is generated because thermoplastic materials can be re-melted during the production process allowing for both a chemical and mechanical bond.

A process that makes the difference

Kingdaflex unique bonding process creates projections on the outside of the core that extend up into the braid, while the jacket material is forced down into the braid from the outside. Each hose has specific dominant characteristics, such as increased abrasion resistance or consistent long lengths to reduce leak points. These hoses easily handle the high temperatures and environmental stress that break down rubber hoses, causing premature hose failure, unexpected safety risks, and downtime, as well as, lost revenue from clean-up and on-site job repairs.

In the past, the majority of hoses were made from rubber but today, a thermoplastic hose may outlive conventional rubber products for several reasons.

Rubber hose can crack from low-temperature embrittlement; therefore, it may not work well in freezers and cold weather.

Thermoplastics are designed to handle low temperatures.

Rubber may fatigue from the constant flexing motion experienced in many applications.

The thermoplastic hose can have a fiber reinforcement bonded between the hose and the jacket designed to handle constant flexing, even at higher pressures.

In addition, these hoses offer good chemical/corrosion resistance and can be formed for easy routing or bonded together to create a single unit from multiple hoses.

Many thermoplastic materials are inherently abrasion-resistant. In fact, thermoplastics are often added to rubber hose covers to increase most rubber hose manufacturers add thermoplastic to hose covers to increase the abrasion resistance of their hoses.

If you any interested in our hose, please contact us.