As a leading nylon braided hose manufacturer, we specialize in producing durable hoses designed for a wide range of applications, including air, water, and low-pressure hydraulic systems. Our commitment to using premium-grade nylon materials and advanced braiding technology ensures that every hose we produce offers exceptional flexibility, high tensile strength, and excellent resistance to abrasion and chemicals. We stand out for our ability to provide customizable solutions that meet the specific needs of our clients, delivering products that guarantee long-lasting performance and reliability.

Exceptional Durability: Made with robust nylon braiding, our hoses withstand high-pressure conditions and are highly resistant to wear and tear.

Customization Options: We offer tailored solutions for length, diameter, and color to meet your specific project requirements.

Chemical and Abrasion Resistance: Our hoses are engineered to perform reliably in harsh environments, resisting a wide range of chemicals and preventing damage from abrasion.

Flexibility and Lightweight Design: The braided nylon construction provides superior flexibility, making our hoses easy to install and handle, while also being significantly lighter than traditional rubber hoses.

Kingdaflex offers wholesale nylon braided hoses for various applications. Our hoses are known for their durability, flexibility, and resistance to abrasion and chemicals. We provide a cost-effective solution for businesses needing bulk quantities without compromising on performance or quality.

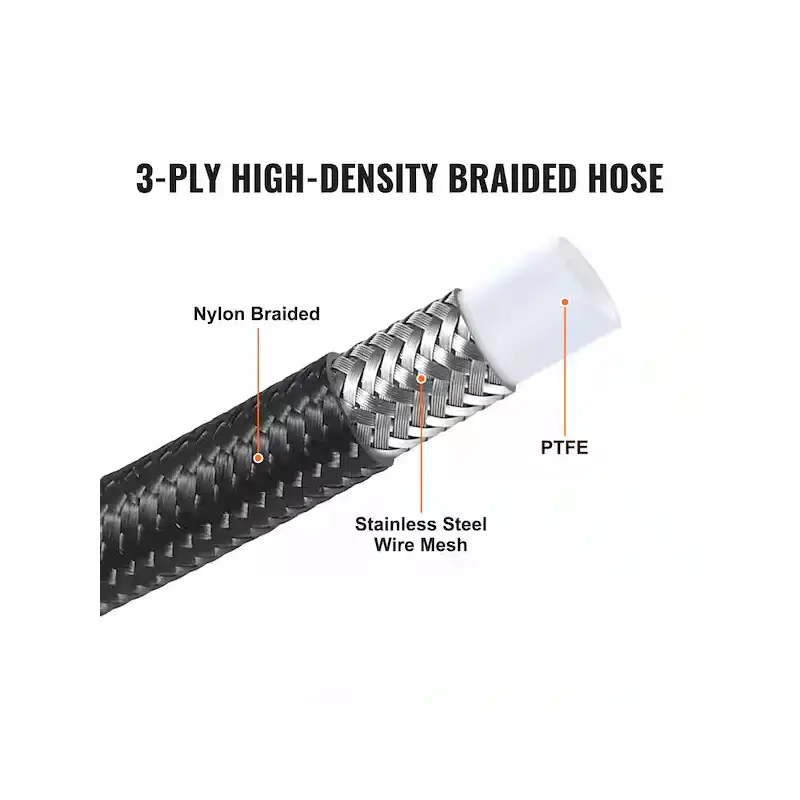

Inner Tube (PTFE): This is the innermost layer that comes into direct contact with the fluid. It’s often made from PTFE (Polytetrafluoroethylene), a material known for its excellent chemical resistance, wide temperature range, and non-stick properties. PTFE prevents the hose from degrading when used with various fluids, including fuels and oils.

Reinforcement Layer (Stainless Steel Wire Mesh): Surrounding the inner tube is a layer of stainless steel wire mesh. This reinforcement provides the hose with its primary structural integrity and pressure rating. The braided steel mesh prevents the hose from expanding or bursting under high pressure, making it incredibly strong and durable.

Outer Cover (Nylon Braided): The outermost layer is a nylon braid. This sheath protects the inner layers from external damage such as abrasion, cuts, and environmental factors. The nylon braid also contributes to the hose’s flexibility and is often chosen for its aesthetic appeal and light weight compared to a full metal casing.

Automotive and Motorsport: Widely used as fuel lines, oil lines, and brake hoses in both street and race cars. Their light weight and resistance to heat and chemicals are major benefits.

Air and Water Transfer: The hoses’ flexibility and durability make them an excellent choice for air compressor lines, pneumatic tools, and general-purpose water transfer in industrial settings.

Marine Applications: They are well-suited for use in boats and marine environments due to their resistance to corrosion, saltwater, and moisture, commonly used for fuel and oil transfer.

Low-Pressure Hydraulic Systems: While not for extreme high pressure, they are often used in low-pressure hydraulic applications where their flexibility and abrasion resistance are key.

General Industrial Use: They can be found in a variety of industrial machines and equipment for the transfer of various non-corrosive fluids and gases.

We specialize in the manufacturing of a wide range of nylon braided hoses, including black and clear varieties. Our hoses feature a durable construction with high-quality nylon fibers, providing excellent flexibility, abrasion resistance, and reliability for various fluid transfer applications.

We offer premium nylon braided fuel line hoses for superior performance and safety. Our nylon braided hoses are engineered with a durable inner tube and a robust nylon braided cover, providing excellent resistance to fuel, oil, and high temperatures. They are designed to prevent kinking and abrasion, ensuring a long-lasting and reliable fuel transfer solution for your vehicle.

We offer high-performance nylon braided rubber hoses that combine the best of both materials. The inner rubber core provides exceptional flexibility and a secure seal for various fluids, while the robust nylon braid on the exterior delivers superior protection against abrasion and cuts. This hybrid design ensures a lightweight yet incredibly durable hose for demanding applications.

Kingdaflex offers nylon braided washer hoses engineered for superior performance and durability. Our hoses feature a robust braided exterior that resists kinking and abrasion, while the inner core withstands high pressure and temperature. They provide a reliable, leak-proof connection, ensuring peace of mind for your washing machine or other water appliances.

We offer a comprehensive selection of nylon braided flex hoses for various industrial and automotive needs. Our hoses provide excellent flexibility and durability, featuring a strong nylon braided cover for superior abrasion resistance. These hoses are ideal for applications requiring a lightweight, high-performance solution that can withstand tough conditions.

We offer clear nylon air hoses designed for optimal performance in pneumatic systems. Our hoses are made from durable nylon, providing excellent transparency to easily monitor fluid flow. They are lightweight, flexible, and resistant to kinking and abrasion, making them a reliable choice for air compressors, air tools, and industrial pneumatic applications.

We offer premium nylon braided air hoses that deliver exceptional performance for a wide range of pneumatic applications. Our hoses are built to last, featuring a durable nylon braid that provides superior resistance to abrasion, kinking, and environmental damage. We supply these high-quality, flexible hoses in various lengths and diameters to meet your specific needs.

We offer premium nylon braided water hoses that are lightweight, durable, and highly flexible, making them perfect for a wide range of applications. Our hoses are built with nylon braiding for superior resistance to kinks, abrasion, and punctures, ensuring reliable water transfer for your home, garden, or industrial needs.

We offer high-performance PTFE braided hoses engineered for demanding fluid transfer. Their non-stick PTFE inner tube provides superior chemical and high-temperature resistance, while the external stainless steel or nylon braid offers exceptional strength and durability. This robust combination ensures our hoses deliver reliable, long-lasting performance in the most critical applications.

We offer a comprehensive selection of PVC braided hoses, engineered for exceptional performance in various applications. Our hoses are constructed with a high-tensile polyester yarn reinforcement, providing superior pressure resistance and dimensional stability. They are highly flexible, resistant to kinks, and are suitable for the transfer of air, water, and select chemicals in industrial and agricultural settings.

We understand that every application is unique, which is why we offer complete customization for your nylon braided hoses. Our services ensure you get a product perfectly suited for your specific requirements, providing optimal performance and a perfect fit.

We can manufacture your nylon braided hoses to any specific length and diameter your project requires. This tailored approach ensures a perfect fit for your equipment, eliminating waste and the need for awkward connections. We precisely match your specifications for optimal performance and efficiency.

We offer a wide range of color options for the outer nylon braid. This customization allows for easy color-coding of different fluid lines, which enhances safety and maintenance efficiency. Additionally, a custom color can be a simple way to align the hose with your brand’s aesthetic.

We can adjust the reinforcement material to meet your specific pressure requirements. Whether you need a stronger stainless steel wire mesh for high-pressure applications or a polyester braid for greater flexibility and lighter weight, we build the hose to your exact performance specifications.

We customize the inner tube material to ensure it is chemically compatible with the specific fluids you will be transferring. For example, we offer PTFE for strong chemical resistance or high-grade PVC for general purpose applications. This guarantees the integrity of your fluid and the hose’s lifespan.

Braided nylon hoses are favored for their superior flexibility, lighter weight, and resistance to abrasion, making them ideal for high-vibration applications. In contrast, braided stainless steel hoses offer higher pressure ratings and greater durability against physical impact and heat. The choice depends on the specific demands

Weight: Nylon hoses are significantly lighter than their stainless steel counterparts, making them ideal for high-performance applications like motorsports where every pound matters.

Flexibility: The soft, woven nylon outer layer gives the hose excellent flexibility, allowing for tighter bends and easier routing in confined spaces without kinking.

Abrasion Resistance: The tightly woven nylon braid provides superior protection against abrasion and rubbing, which helps to extend the hose’s lifespan in harsh or high-vibration environments.

Cost: Generally, nylon braided hoses are more cost-effective to manufacture, making them a more budget-friendly option for projects where extreme pressure ratings are not required.

Pressure Rating: Stainless steel braiding offers superior tensile strength and is designed to handle much higher operating pressures, making it the standard for demanding hydraulic and fluid transfer systems.

Heat Resistance: Stainless steel is highly resistant to heat and is the preferred choice for applications near high-temperature components like exhaust manifolds.

Puncture Resistance: The metal braid provides robust protection against punctures and cuts from sharp objects or debris, offering a higher level of physical durability.

Aesthetics: Stainless steel braided hoses are often chosen for their classic, rugged appearance, which is a popular aesthetic in performance automotive and industrial settings.

The manufacturing process of a nylon braided hose is a precise, multi-stage operation designed to create a product that can withstand high pressure, abrasion, and chemicals. Each step, from extruding the inner tube to applying the final nylon braid, is carefully controlled to ensure the hose meets strict performance and durability standards.

Inner Tube Extrusion: The process begins with the extrusion of the inner tube, typically made from materials like PTFE or PVC. This forms a seamless, non-porous core that is compatible with various fluids and chemicals.

Reinforcement Braiding: The inner tube is fed into a braiding machine that weaves a high-tensile material, such as stainless steel wire or polyester yarn, around it. This layer provides the hose with its primary strength and pressure rating.

Outer Cover Extrusion (Optional): Some hoses feature an optional intermediate layer of rubber or PVC extruded over the reinforcement to add flexibility and additional protection before the final braid is applied.

Nylon Braiding: The final step involves braiding the nylon fibers over the hose’s exterior. This layer provides superior abrasion resistance, protects the inner layers from environmental damage, and gives the hose its distinct appearance.

Final Processing: The completed hose is then cured to bond the layers, cut to specific lengths, thoroughly cleaned to prevent contamination, and capped for protection before being packaged for shipment.

A nylon braided hose is a type of hose designed for durability and flexibility, primarily used for transferring various fluids and gases.

It’s constructed with a multi-layer design, featuring a smooth, chemically resistant inner tube, a reinforcement layer often made of braided polyester or stainless steel wire, and an outer cover consisting of a tightly woven nylon braid.

This outer layer gives the hose its characteristic rugged appearance while providing exceptional resistance to abrasion, cuts, and environmental factors. The combination of these layers makes the hose lightweight, kink-resistant, and capable of withstanding moderate pressures, making it a popular choice for automotive, industrial, and marine applications.

Nylon braided hose is used to transfer a variety of fluids and gases in applications that require a lightweight, flexible, and durable conduit. Its construction, featuring an inner tube, reinforcement layer, and a distinctive woven nylon exterior, makes it well-suited for environments where resistance to abrasion, chemicals, and kinking is important.

This hose is a popular choice for both performance and general-purpose use due to its reliability and clean appearance.

Automotive and Motorsports: Used for fuel, oil, and brake lines due to its light weight and resistance to heat and pressure.

Air and Water Transfer: Ideal for air compressor lines, pneumatic tools, and general-purpose water delivery because of its flexibility and durability.

Marine Applications: Utilized in boats for fuel lines and other fluid transfer systems as it resists corrosion from moisture and saltwater.

Low-Pressure Hydraulics: Employed in hydraulic systems where lower pressures are involved, benefiting from its flexibility and resistance to kinking.

There is no single “better” hose; the choice between a nylon or stainless braided hose depends entirely on the specific application’s requirements.

While both provide reinforcement and protection, they excel in different areas. Nylon braided hose is generally the superior choice when lightweight design, flexibility, and abrasion resistance are the top priorities.

Conversely, a stainless braided hose is the better option for applications that demand high pressure resistance, extreme heat tolerance, and protection against physical impact.

Nylon Braided Hose:

Stainless Steel Braided Hose:

The temperature rating for nylon braided hose varies depending on the specific materials used for the inner tube and outer braid.

Typically, these hoses are suitable for a wide range of operating temperatures, commonly handling fluids from as low as −40∘F (−40∘C) up to 250∘F (121∘C).

While the outer nylon braid can withstand a broad temperature range, the primary limiting factor is often the inner tube material, such as PTFE or synthetic rubber, which determines the hose’s maximum and minimum operational temperatures.

When you choose our nylon braided hoses, you’re selecting a product engineered for superior performance and reliability. We use only premium-grade materials, from the smooth, chemically resistant PTFE inner tube to the high-tensile nylon braid. This meticulous construction ensures that our hoses are not only lightweight and flexible but also exceptionally durable, resisting abrasion, kinking, and environmental damage far better than standard hoses.

Our commitment to quality extends beyond the materials. We offer extensive customization for your specific needs, allowing you to select the precise length, diameter, and color to ensure a perfect fit and visual distinction for your application.

This dedication to precision, combined with a manufacturing process built on stringent quality control, guarantees that every hose we produce will deliver long-lasting, leak-free performance, providing you with a reliable solution you can trust.