![]()

Peristaltic hose pumps have revolutionized fluid transfer systems across industries. Their unique design and outstanding performance make them an ideal choice for various applications.

In this comprehensive article, we will delve into what peristaltic hose pumps are, explore their working mechanism, examine their applications, and understand why they have garnered such popularity.

Get ready to unlock the secrets of this innovative technology and gain insights into how it can benefit your industry.

What Are Peristaltic Hose Pumps?

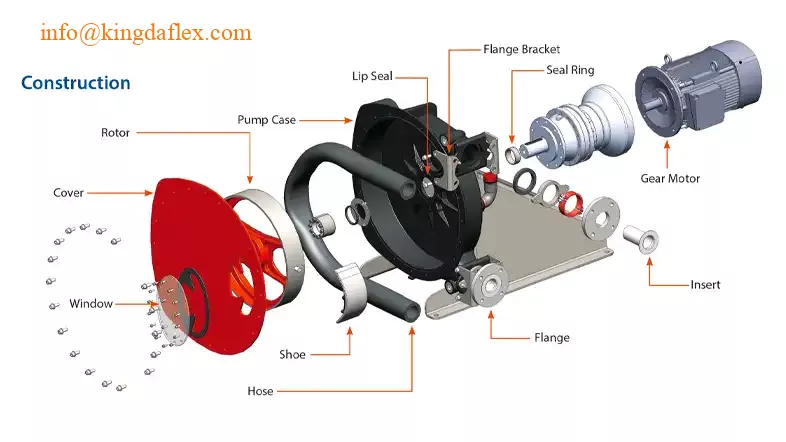

Peristaltic hose pumps, also known as peristaltic pumps or hose pumps, are positive displacement pumps that use a specially designed tube to transfer fluids. The defining feature of these pumps is their peristaltic action, where a rotor compresses and relaxes the hose to create a continuous flow of fluid. This mechanism eliminates the need for seals, valves, or diaphragms, making peristaltic hose pumps highly efficient and reliable.

The Working Mechanism of Peristaltic Hose Pumps

To understand the working mechanism of peristaltic hose pumps, imagine squeezing a toothpaste tube. When you apply pressure on the tube, toothpaste is forced out through the opening.

Similarly, in a peristaltic hose pump, a rotating rotor with rollers or shoes compresses the flexible tube, pushing the fluid forward through the hose.

As the rotor continues to rotate, the section of the hose behind the compression point relaxes, creating a vacuum that draws more fluid into the pump. This repetitive squeezing and relaxing motion ensures a continuous, smooth flow of the fluid without any backflow.

The simplicity of this design not only enhances reliability but also allows for gentle pumping of shear-sensitive and abrasive fluids.

The Advantages of Peristaltic Hose Pumps

Peristaltic hose pumps offer a multitude of advantages over other types of pumps, making them a preferred choice in various industries:

- Versatility: These pumps can handle a wide range of fluids, from thin, watery solutions to viscous and abrasive materials, making them highly versatile.

- Gentle Pumping: The squeezing action is gentle on fluids, making peristaltic hose pumps suitable for shear-sensitive substances, such as blood and pharmaceuticals.

- Dry Running: Peristaltic pumps can run dry without damage to the pump or the fluid being transferred, enhancing their safety and reliability.

- Self-Priming: They have excellent self-priming capabilities, which means they can start pumping without the need for additional priming mechanisms.

- Reversible Operation: Peristaltic hose pumps can reverse their flow direction by changing the rotor’s rotation, offering operational flexibility.

- Minimal Maintenance: Since the fluid only comes into contact with the tube, wear is limited to the replaceable hose, reducing maintenance requirements.

- No Contamination: The hose acts as a barrier, preventing the fluid from contacting other pump components, ensuring no contamination of the fluid being transferred.

- Cost-Effective: With reduced maintenance needs, longevity, and easy tube replacement, peristaltic hose pumps are cost-effective in the long run.

- High Pressure and Flow Rates: These pumps can handle high-pressure applications and deliver consistent flow rates.

- Quiet Operation: Peristaltic hose pumps operate quietly, making them suitable for noise-sensitive environments.

Applications of Peristaltic Hose Pumps

Peristaltic hose pumps find applications in diverse industries due to their versatility and efficiency. Some of the notable applications include:

1. Water Treatment and Wastewater Management

In water treatment plants, peristaltic hose pumps are used for dosing and transferring chemicals, such as coagulants and flocculants, accurately. Their precise metering capability ensures effective water purification processes. Additionally, in wastewater management, these pumps handle sludge, lime, and other abrasive materials efficiently.

2. Pharmaceuticals and Biotechnology

The pharmaceutical and biotechnology industries rely on peristaltic hose pumps for precise and sterile fluid transfer. These pumps are utilized in drug manufacturing, chromatography, fermentation, and many other critical processes.

3. Food and Beverage

Peristaltic hose pumps play a crucial role in the food and beverage industry, where gentle handling of sensitive fluids is paramount. They are used in bottling, flavor dosing, and transferring delicate ingredients.

4. Mining and Construction

In mining and construction, these pumps handle abrasive slurry, grout, and other challenging materials effectively. Their ability to run dry without damage makes them ideal for such applications.

5. Chemical and Industrial Processing

Peristaltic hose pumps are extensively used in chemical processing for transferring corrosive and hazardous chemicals safely. They are also employed in industrial processes for metering and dosing various fluids accurately.

6. Medical and Laboratory Settings

In medical settings, these pumps are used for drug delivery, blood circulation during surgeries, and other precision tasks. Laboratories use them for fluid handling in analytical instruments.

Frequently Asked Questions (FAQs)

Are peristaltic hose pumps suitable for pumping viscous fluids?

Yes, peristaltic hose pumps are well-suited for pumping viscous fluids. Their squeezing action ensures a smooth flow even with thick and sticky substances, making them highly efficient in handling such materials.

How often should I replace the pump hose?

The frequency of hose replacement depends on the pump’s usage and the type of fluid being transferred. Generally, hoses can last for several months to a few years, but it is essential to inspect them regularly and replace them as needed to avoid any disruptions in the pumping process.

Can peristaltic hose pumps run dry without damage?

Yes, one of the notable advantages of peristaltic hose pumps is their ability to run dry without causing damage to the pump or the fluid being transferred. This feature enhances their safety and reliability.

Do peristaltic hose pumps require priming before use?

No, peristaltic hose pumps have excellent self-priming capabilities. They can start pumping without the need for additional priming mechanisms, simplifying their operation.

Are peristaltic hose pumps suitable for shear-sensitive fluids?

Yes, peristaltic hose pumps are gentle on fluids, making them suitable for pumping shear-sensitive substances like blood, pharmaceuticals, and delicate solutions.

Can peristaltic hose pumps handle abrasive materials?

Absolutely, peristaltic hose pumps are designed to handle abrasive materials, such as slurry and lime, effectively. Their robust construction and replaceable hoses make them ideal for such applications.

Conclusion

Peristaltic hose pumps have emerged as a game-changer in the field of fluid transfer technology. Their unique working mechanism, versatility, and reliability have made them indispensable across various industries. From pharmaceutical