We offer reinforced hydraulic hoses designed for demanding industrial and mobile applications. Engineered to withstand high pressure and extreme conditions, our hoses ensure reliability, durability, and safety. Perfect for hydraulic systems in construction, agriculture, and manufacturing, these hoses maintain consistent performance while reducing downtime. Trust our reinforced hydraulic hoses to deliver strength, flexibility, and long service life.

Durable Construction: Made with multiple layers of strong reinforcement materials, providing excellent resistance to pressure, abrasion, and harsh environmental conditions, ensuring long-lasting performance.

High Pressure Performance: Designed to handle high-pressure hydraulic systems efficiently, maintaining safety and reliability in extreme working environments without risk of failure.

Flexible Design: Despite heavy-duty reinforcement, our hoses remain flexible, allowing easy installation and adaptability in tight spaces, enhancing operational convenience.

Chemical and Temperature Resistance: Resistant to oils, chemicals, and wide temperature ranges, ensuring stable performance in challenging industrial and mobile applications.

Wide Range of Sizes: Available in various diameters and lengths, accommodating diverse hydraulic systems and applications while meeting specific operational requirements.

We are a leading reinforced hydraulic hose manufacturer from China, specializing in high-quality, durable hoses for industrial and mobile applications. Our hoses are designed to withstand high pressure, extreme temperatures, and harsh conditions, ensuring reliable performance. With strict quality control, competitive pricing, and customizable options, we provide reinforced hydraulic hoses that meet global standards and keep your systems running efficiently.

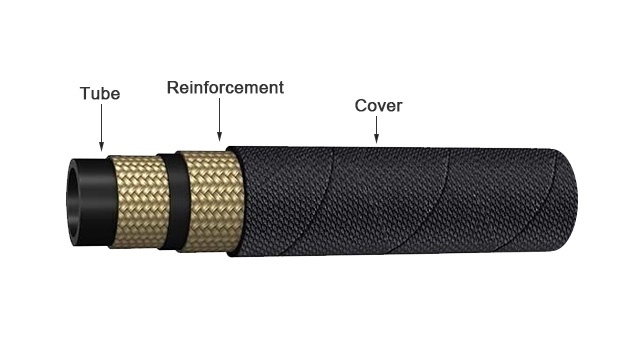

Inner Tube – Made of synthetic rubber or thermoplastic, it resists hydraulic fluid, prevents leakage, and ensures smooth flow under high-pressure conditions.

Reinforcement Layer – Consists of steel wire or textile braid, providing strength, pressure resistance, and durability while maintaining flexibility for various applications.

Outer Cover – Made of wear-resistant rubber or synthetic material, it protects the hose from abrasion, weather, chemicals, and environmental damage for long-lasting performance.

End Fittings – Crimped or threaded fittings ensure secure connections to machinery, prevent leaks, and enable reliable operation in high-pressure hydraulic systems.

Optional Protective Layers – Extra layers like spiral wraps or anti-static coatings provide additional protection, heat resistance, or safety in specialized high-pressure or hazardous environments.

Steel Wire Reinforced Hydraulic Hose

These hoses feature multiple layers of high-tensile steel wire for superior pressure resistance, making them ideal for heavy-duty industrial and construction applications requiring durability and reliability.

Textile Reinforced Hydraulic Hose

Reinforced with synthetic fibers, these hoses offer flexibility and moderate pressure resistance, perfect for agricultural, automotive, and light industrial uses where easy handling is essential.

Spiral Reinforced Hydraulic Hose

Constructed with a spiral of steel wire inside the hose, they can handle extremely high pressure, making them suitable for mining, oilfield, and heavy machinery operations.

Braided Reinforced Hydraulic Hose

Braided hoses use woven wire layers to provide strength and flexibility, ideal for medium-pressure systems in mobile and industrial hydraulic equipment.

Rubber Reinforced Hydraulic Hose

These hoses combine rubber compounds with textile or steel reinforcement, offering excellent wear resistance, high-pressure tolerance, and long-term reliability in harsh environments.

We offer reinforced hydraulic hoses designed for high-pressure applications in industrial, construction, and mobile machinery. Built with durable inner tubes, strong steel or textile reinforcement, and wear-resistant outer covers, our hoses ensure reliable performance and long service life. With customizable lengths, fittings, and protective layers, we provide solutions that meet global standards and keep your hydraulic systems running efficiently.

We provide wire reinforced hydraulic hoses designed for high-pressure hydraulic systems in industrial and mobile applications. Featuring durable inner tubes, multiple layers of steel wire reinforcement, and wear-resistant outer covers, our hoses ensure safety, reliability, and long service life. We supply customizable lengths and fittings to meet diverse operational requirements efficiently and effectively.

We offer textile reinforced hydraulic hoses designed for durability and reliable performance in demanding hydraulic systems. Our hoses provide excellent flexibility, resistance to pressure, and long service life. We supply hoses suitable for various industrial applications, ensuring safety and efficiency. Trust us to deliver premium textile reinforced hydraulic hoses that meet your needs.

We supply wire reinforced hydraulic rubber hoses designed for durability and reliable performance in high-pressure applications. Our hoses feature multiple layers of strong wire reinforcement, ensuring excellent resistance to pressure, wear, and environmental factors. We provide flexible, long-lasting solutions suitable for industrial machinery, construction equipment, and hydraulic systems, meeting global quality standards and customer requirements.

We understand that every hydraulic system has unique requirements, so we offer fully customizable reinforced hydraulic hoses to meet your specific needs. From pressure ratings to material selection, we work closely with our clients to ensure optimal performance, safety, and longevity for their hydraulic applications across various industries.

We help you select the exact hose diameter and length to match your system’s flow and connection requirements. By customizing these dimensions, we ensure optimal performance, prevent pressure loss, and reduce the risk of leaks, making your hydraulic operations safer and more efficient.

We provide hoses made from premium rubber and specialized reinforcement materials, along with customizable outer covers. By selecting materials resistant to oil, heat, abrasion, or chemicals, we ensure your hoses perform reliably under harsh conditions, extending durability and reducing maintenance needs.

We customize hoses to withstand extreme temperatures and challenging environmental conditions. By choosing the right construction and protective layers, we ensure your hoses maintain flexibility, strength, and performance even under heat, cold, UV exposure, or corrosive environments.

We offer reinforced hydraulic hoses with a variety of pressure ratings to suit different applications. By tailoring the hose reinforcement layers and materials, we ensure it can withstand high-pressure conditions, providing reliable performance, extended service life, and minimizing the risk of failures or downtime.

A reinforced hydraulic hose is a flexible tube designed to transport hydraulic fluids under high pressure while maintaining structural integrity. Unlike standard hoses, it includes one or more layers of reinforcement—such as braided textile, steel wire, or spiral wire—embedded between the inner tube and outer cover. This reinforcement allows the hose to withstand extreme pressures, resist kinking, and maintain flexibility for reliable fluid transmission in hydraulic systems.

Reinforced hydraulic hoses are widely used in industrial, construction, agricultural, and automotive applications where durability and safety are critical. They provide resistance to abrasion, temperature variations, and chemical exposure while ensuring smooth operation of machinery and equipment. By combining strong reinforcement with high-quality rubber or synthetic materials, these hoses deliver long-lasting performance and reduce the risk of leaks or failures in demanding environments.

Reinforced hydraulic hoses are carefully engineered using multiple layers of materials to ensure strength, flexibility, and resistance to pressure and environmental factors.

Each layer contributes to the hose’s overall durability, allowing it to perform reliably in demanding hydraulic systems across industries.

Inner Tube: The inner tube is typically made from synthetic rubber or thermoplastic materials. We select materials that are compatible with hydraulic fluids, ensuring smooth flow while resisting corrosion, chemical degradation, and pressure. This foundation layer maintains the hose’s integrity and supports the reinforcement layers effectively.

Reinforcement Layer: The reinforcement layer consists of braided or spiraled textile, steel wire, or a combination of both. We design this layer to withstand high pressure, prevent hose expansion, and provide structural support. Proper reinforcement ensures long-term durability and safe operation under extreme hydraulic conditions.

Outer Cover: The outer cover is made from durable rubber or synthetic compounds. We provide materials resistant to abrasion, ozone, UV exposure, and harsh environmental factors. This protective layer shields the hose from external damage, extending its service life while maintaining flexibility and performance in challenging applications.

Optional Fabric or Shield Layers: Some hoses include additional fabric or protective shield layers. We incorporate these layers to enhance resistance against mechanical wear, cuts, or environmental stress. They add an extra level of safety and reliability, particularly for hoses exposed to rough industrial or outdoor conditions.

Reinforced hydraulic hoses are essential components in hydraulic systems, transferring fluid power safely and efficiently. Their strong construction allows them to operate under high pressure and harsh conditions, making them suitable for a wide range of industrial, automotive, and construction applications where reliability and performance are critical.

Industrial Machinery: We use reinforced hydraulic hoses in industrial machinery to transmit hydraulic fluid under high pressure, ensuring smooth operation of presses, lifts, and automated equipment while providing durability, flexibility, and long-term consistent performance.

Construction Equipment: We supply hoses for construction machinery like excavators, loaders, and cranes, handling extreme pressures and harsh environments to ensure reliable fluid power transmission, improve equipment efficiency, and reduce downtime.

Agricultural Machinery: We provide hydraulic hoses for tractors, harvesters, and irrigation systems, designed to withstand chemical exposure, high pressure, and outdoor conditions, ensuring consistent operation and minimizing maintenance for productive farming.

Automotive Applications: We offer reinforced hydraulic hoses for vehicle systems including brakes, power steering, and suspension, delivering safe and efficient fluid transfer, resisting temperature variations, and providing long-lasting performance under constant movement.

Marine and Offshore Equipment: We customize hoses for marine and offshore hydraulic systems, resisting saltwater, UV, and extreme temperatures to maintain hydraulic efficiency for pumps, winches, and steering systems in demanding environments.

Choosing the right reinforced hydraulic hose is crucial for ensuring safety, reliability, and optimal performance in hydraulic systems. Our hoses are engineered with high-quality materials, advanced reinforcement layers, and precise manufacturing standards, providing long-lasting durability and efficiency across various industrial, automotive, construction, and agricultural applications.

High-Quality Materials: We use premium rubber, synthetic compounds, and durable reinforcement wires to construct our hoses, ensuring resistance to pressure, abrasion, temperature extremes, and chemicals. This guarantees long-lasting performance, reduced maintenance, and reliable fluid transfer even in the most demanding hydraulic environments.

Durable Reinforcement Layers: We design hoses with multiple layers of textile or steel wire reinforcement. This structure prevents hose expansion, ensures consistent pressure handling, and provides structural strength, offering safer operation and prolonged service life for machinery and hydraulic systems under high-pressure conditions.

Wide Range of Sizes and Pressure Ratings: We offer hoses in various diameters, lengths, and pressure ratings to match different applications. By customizing specifications, we ensure compatibility, optimal flow, and efficient system performance, reducing downtime and improving the overall reliability of hydraulic operations.

Versatile Applications: We provide hoses suitable for industrial machinery, construction equipment, automotive systems, and agricultural machinery. Our hoses handle harsh conditions and extreme pressures, ensuring smooth operation, flexibility, and safety across multiple industries and hydraulic system requirements.

Exceptional Customer Support: We assist customers in selecting, customizing, and maintaining the right hoses for their applications. By offering expert guidance, technical support, and after-sales service, we help clients maximize hose performance, extend service life, and achieve efficient and safe hydraulic operations.