SAE J2527 sets the benchmark for environmental testing of automotive materials, particularly hydraulic hose assemblies. Understanding this standard is crucial for ensuring the longevity and reliability of your hydraulic systems. This blog will delve into the intricacies of SAE J2527, explaining its significance in evaluating material durability against environmental stressors.

We’ll explore how SAE J2527 testing procedures simulate real-world conditions, providing insights into material performance under various environmental factors. This knowledge will empower you to make informed decisions when selecting hydraulic hoses, ultimately extending the lifespan of your assemblies and minimizing system failures.

What Is SAE

SAE International, formerly known as the Society of Automotive Engineers, is a globally recognized standards development organization. While it covers a broad spectrum of engineering fields, its standards are particularly crucial in the hydraulic hose industry.

SAE standard hydraulic hoses provide specific guidelines for the design, construction, testing, and performance of hydraulic hoses, ensuring they meet the demanding requirements of various applications. These standards are developed by industry experts to promote safety, reliability, and compatibility within hydraulic systems.

For hydraulic hoses, SAE standards define critical parameters such as pressure ratings, temperature resistance, dimensional accuracy, and material compatibility. Adhering to these standards ensures that hydraulic hoses from different manufacturers can be interchanged and that they perform consistently under specified conditions. This standardization is essential for maintaining the integrity and safety of hydraulic systems across industries like construction, agriculture, and automotive.

What Is SAE J2527

SAE J2527 is a standard published by SAE International that specifically addresses the environmental exposure testing of automotive materials, with significant implications for the hydraulic hose industry.

It outlines standardized procedures for evaluating the durability and performance of hydraulic hose assemblies when subjected to environmental stressors such as temperature variations, humidity, and UV radiation. This standard is crucial for ensuring that hydraulic hoses maintain their integrity and functionality over their lifespan, particularly in demanding automotive applications where they are exposed to harsh conditions.

Within the hydraulic hose industry, SAE J2527 helps manufacturers and users select and develop hoses that can withstand real-world environmental challenges. By simulating these conditions through rigorous testing, the standard ensures that hydraulic systems remain reliable and safe, minimizing the risk of premature hose failure and reducing maintenance costs. This standard is a critical tool for guaranteeing the long-term performance and reliability of hydraulic hose assemblies in automotive environments.

SAE J1960 vs SAE J2527

SAE J1960 and SAE J2527 are both SAE standards that deal with testing hydraulic hose assemblies, but they focus on different aspects of hose performance and application.

SAE J1960 is primarily concerned with the performance of hydraulic hoses specifically used in automotive power steering systems, while SAE J2527 addresses the broader environmental durability of hydraulic hoses and other automotive materials. Understanding these differences is crucial for selecting the appropriate testing standards for specific hydraulic hose applications.

Here are the key differences between these two standards:

SAE J1960 – Power Steering Hose Assemblies:

This standard focuses on the dynamic and pressure-related performance of hydraulic hoses in automotive power steering systems. It includes testing for impulse fatigue, burst pressure, and temperature cycling, simulating the demanding conditions of power steering applications. It is designed to ensure the hose assemblies can withstand the constant pressure and temperature changes associated with power steering.

SAE J2527 – Environmental Exposure Testing:

This standard focuses on the environmental durability of hydraulic hoses and other automotive materials. It includes testing for resistance to UV radiation, temperature variations, and humidity, simulating long-term exposure to real-world conditions. This standard is designed to evaluate how well hose assemblies maintain their integrity and performance over time when exposed to various environmental stressors.

Comparison chart about the differences between SAE J1960 and SAE J2527:

| Feature | SAE J1960 | SAE J2527 |

| Focus | Power steering hose performance | Environmental durability |

| Application | Automotive power steering systems | General automotive materials, including hydraulic hoses |

| Testing Type | Impulse fatigue, burst pressure, temperature cycling | UV radiation, temperature variations, humidity |

| Goal | Ensure performance under dynamic pressure and temperature changes | Ensure durability under long-term environmental exposure |

SAE J2527 Test Duration

The duration of an SAE J2527 test can vary significantly depending on the specific environmental conditions being simulated and the materials being tested. This standard doesn’t prescribe a fixed duration; rather, it outlines the procedures and parameters for exposing materials to environmental stressors like UV radiation, temperature, and humidity. The test duration is typically determined based on the desired level of exposure and the expected lifespan of the material in real-world conditions.

Factors influencing the test duration include the intensity of UV radiation, the range and cycling of temperature variations, and the level of humidity. Test durations can range from several hundred hours to thousands of hours, depending on the severity of the environmental conditions being simulated. The goal is to accelerate the aging process and evaluate the material’s long-term durability within a reasonable timeframe, providing valuable data for material selection and product design.

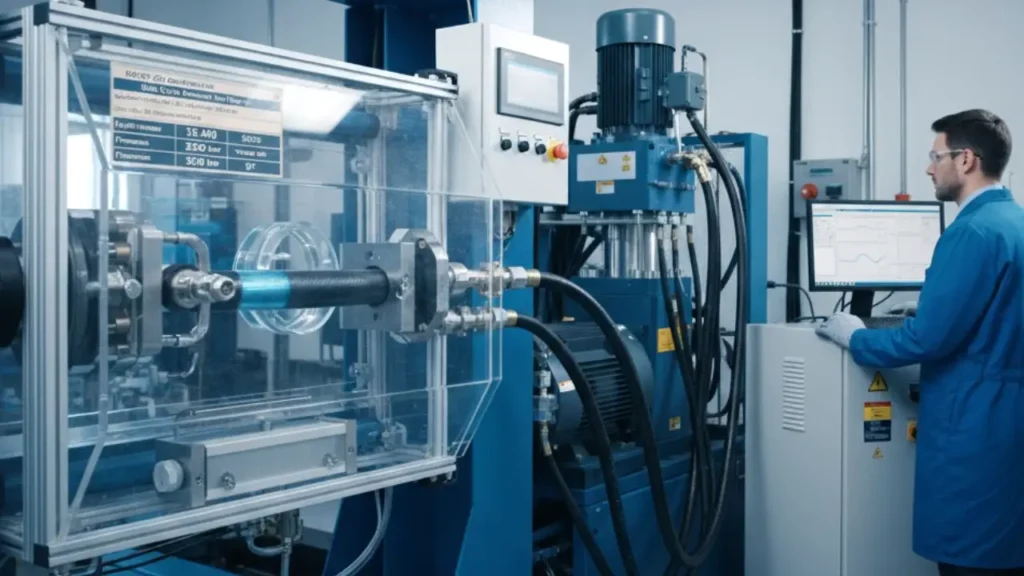

How to Test Hydraulic Hose SAE J2527

Testing hydraulic hoses according to SAE J2527 is critical for assessing their environmental durability and ensuring they can withstand real-world conditions. This standard outlines procedures for evaluating the performance of hydraulic hoses when exposed to environmental stressors, including UV radiation, temperature, and humidity. We will guide you through the process of conducting the hydraulic hose SAE J2527 tests.

Step 1: Sample Preparation and Setup

Before initiating the environmental exposure test, carefully prepare the hydraulic hose samples. Ensure that the samples are representative of the actual hoses used in the application, considering factors such as material composition, dimensions, and construction. Clean the samples to remove any contaminants that could affect the test results. Properly label each sample for accurate tracking throughout the testing process.

Next, set up the environmental chamber or testing equipment according to the specifications outlined in SAE J2527. This typically involves configuring the chamber to simulate the desired environmental conditions, such as specific temperature ranges, humidity levels, and UV radiation intensity. Ensure that the samples are positioned within the chamber to receive uniform exposure to the simulated environment. Accurate setup is crucial for obtaining reliable and consistent test results.

Step 2: Environmental Exposure and Monitoring

Begin the environmental exposure test by activating the testing equipment and initiating the programmed environmental conditions. Monitor the chamber’s temperature, humidity, and UV radiation levels throughout the test to ensure they remain within the specified parameters. Regularly record these measurements to document the actual exposure conditions. This data will be crucial for analyzing the test results and evaluating the hydraulic hose’s performance.

During the exposure period, periodically inspect the hydraulic hose samples for any signs of degradation, such as cracking, discoloration, or loss of flexibility. Document any observed changes and photograph the samples to provide visual evidence of their condition. The frequency of these inspections will depend on the test duration and the expected rate of material degradation. Continuous monitoring and documentation are essential for accurately assessing the hose’s environmental resistance.

Step 3: Performance Evaluation and Analysis

After completing the environmental exposure test, remove the hydraulic hose samples from the chamber and conduct a thorough performance evaluation. This may involve visual inspection, dimensional measurements, and mechanical testing, such as burst pressure or tensile strength tests, to assess any changes in the hose’s properties. Compare the post-exposure test results with the pre-exposure baseline data to determine the extent of material degradation.

Analyze the collected data and observations to evaluate the hydraulic hose’s environmental resistance and determine its suitability for the intended application. Consider factors such as the rate of degradation, the hose’s ability to maintain its functional properties, and any observed changes in its appearance or dimensions. Prepare a comprehensive test report summarizing the testing procedures, results, and analysis. This report will provide valuable information for material selection and product design.

Conclusion

In conclusion, SAE J2527 plays a vital role in ensuring the longevity and reliability of hydraulic hose assemblies by rigorously testing their resistance to environmental stressors. Understanding and adhering to this standard is essential for selecting hoses that maintain performance and safety over time, particularly in demanding automotive applications.

By simulating real-world conditions, SAE J2527 helps manufacturers and users identify hoses capable of withstanding temperature fluctuations, UV radiation, and humidity. This standard ultimately minimizes the risk of premature hose failure, reducing maintenance costs and enhancing overall system efficiency. Prioritizing SAE J2527 compliance ensures your hydraulic systems remain robust and dependable.

For premium hydraulic hoses that meet and exceed industry standards, including those tested under SAE J2527, choose Kingdaflex. We offer a comprehensive range of wholesale solutions tailored to your specific needs. Contact us today to receive a competitive quote and guarantee the lasting performance of your hydraulic systems.