Choosing the right sandblasting hose size is crucial for efficiency, safety, and performance. Our ultimate guide helps you understand hose diameters, lengths, and pressure ratings, ensuring the best fit for your industrial, construction, or automotive applications.

Learn how to select the perfect sandblast hose for every project. Explore sizing tips, compatibility with abrasive media, and factors affecting durability and workflow, so you can achieve professional results with minimal downtime.

What Is Sandblasting Hose

Sandblasting hose is a specialized type of hose designed to withstand the abrasive nature of sandblasting. It is typically made from high-strength materials, such as rubber or synthetic polymers, to resist wear and tear caused by the constant bombardment of sand particles.

These sandblast hoses are used to transport a mixture of compressed air and abrasive material (like sand, glass beads, or metal grit) to a sandblasting gun. The mixture is then forced out of the gun at high pressure, removing surface contaminants and creating a smooth finish on various materials.

Key characteristics of sandblasting hose:

- Durability: Resistant to abrasion, cuts, and punctures.

- Flexibility: Allows for easy maneuverability in different work environments.

- Pressure resistance: Can handle high-pressure air and abrasive materials.

- Chemical resistance: May be resistant to certain chemicals used in sandblasting processes.

- Temperature resistance: Can withstand a wide range of temperatures.

Common applications for sandblasting hose:

- Industrial manufacturing (e.g., automotive, aerospace, shipbuilding)

- Construction (e.g., surface preparation for painting or coating)

- Restoration (e.g., restoring antique or vintage items)

- Art and crafts (e.g., creating unique textures on surfaces)

Would you like to learn more about the different types of sandblasting hose or how to choose the right size for your specific needs?

Abrasive Blasting Hose Size

Choosing the correct abrasive blasting hose size is essential for optimal performance, safety, and efficiency. Hose diameter and length directly affect abrasive flow, pressure, and maneuverability. Understanding size requirements helps prevent equipment damage, reduce wear, and ensure precise surface preparation across various industrial and construction applications.

- Hose Diameter: Selecting the proper diameter ensures adequate abrasive flow while maintaining pressure. A too-small diameter restricts flow, reducing efficiency, while a too-large diameter can decrease abrasive velocity, affecting cleaning quality. Correct sizing balances flow rate, pressure, and precision for consistent blasting results.

- Hose Length: Hose length affects reach, flexibility, and pressure drop. Longer hoses allow access to distant or hard-to-reach areas but may reduce pressure at the nozzle. Choosing the right length ensures safe, effective operation without compromising abrasive delivery or operator control during blasting tasks.

- Pressure Rating Compatibility: Hose size must match the pressure rating of the blasting system. Undersized hoses may burst under high pressure, while oversized hoses can cause unnecessary strain on equipment. Proper matching ensures safety, durability, and consistent performance during abrasive blasting operations.

- Flexibility and Handling: Larger or longer hoses may be stiffer, making maneuvering difficult. Flexible hoses improve operator comfort, precision, and efficiency in tight spaces. Selecting the right size ensures balance between durability, flow capacity, and ease of handling in industrial or construction environments.

- Abrasive Media Type: Different abrasive materials flow differently through hoses. Matching hose size to the media—sand, steel grit, or glass beads—reduces clogging, wear, and maintenance. Properly sized hoses maintain consistent abrasive velocity and efficiency, extending service life and improving surface preparation results.

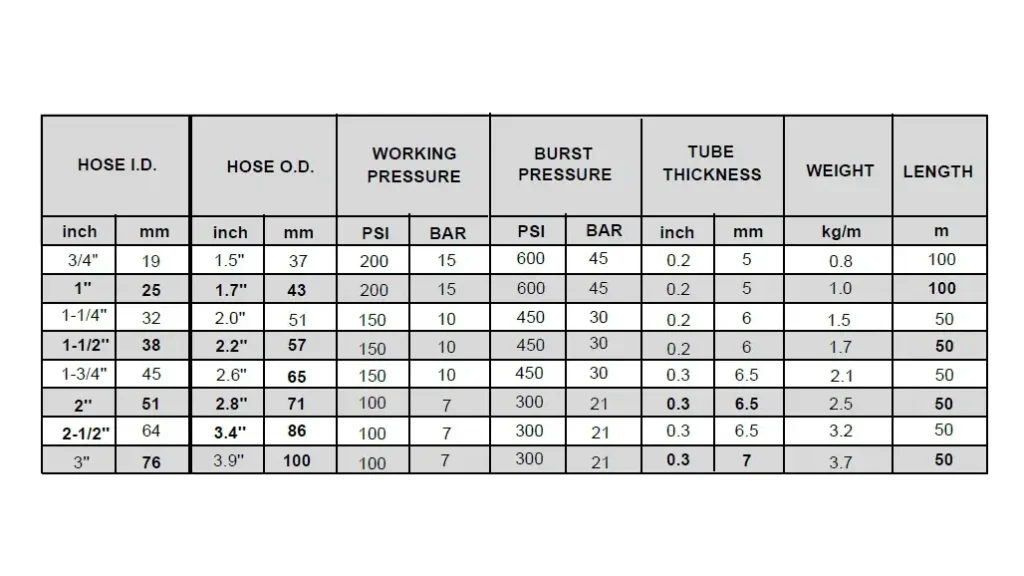

Here is the blasting hose size chart for your conference.

| Air Consumption (CFM) per Blast Nozzle Using Abrasive | ||||||||||||

Nozzle Size | Nozzle Pressure | |||||||||||

| 50 psi | 60 psi | 70 psi | 80 psi | 90 psi | 100 psi | 110 psi | 120 psi* | 130 psi* | 140 psi* | 150 psi* | ||

| No. 2 | ⅛” | 14 | 17 | 19 | 21 | 24 | 26 | 28 | 30 | 32 | 34 | 37 |

| No. 3 | ³/₁₆” | 32 | 37 | 42 | 47 | 52 | 57 | 62 | 67 | 72 | 77 | 83 |

| No. 4 | 1/4” | 57 | 66 | 75 | 84 | 93 | 103 | 111 | 119 | 127 | 136 | 185 |

| No. 5 | ⁵/₁₆” | 89 | 103 | 117 | 131 | 145 | 158 | 172 | 186 | 200 | 214 | 229 |

| No. 6 | ⅜” | 129 | 149 | 169 | 189 | 209 | 229 | 249 | 269 | 289 | 309 | 330 |

| No. 7 | ⁷/₁₆” | 176 | 203 | 230 | 258 | 285 | 312 | 339 | 367 | 394 | 422 | 451 |

| No. 8 | 1/2” | 229 | 265 | 300 | 336 | 371 | 407 | 442 | 478 | 513 | 549 | 586 |

| No. 10 | ⅝” | 356 | 412 | 468 | 524 | 580 | 632 | 688 | 744 | 800 | 856 | 914 |

| No. 12 | ¾” | 516 | 596 | 676 | 756 | 836 | 916 | 996 | 1076 | 1156 | 1236 | 1318 |

| EFFICIENCY | 47% | 55% | 64% | 74% | 86% | 100% | 115% | 130% | 145% | 165% | 175% | |

Ensure your sandblasting equipment is rated for these pressures.

| Nozzle Pressure vs Efficiency | ||

| Blast Nozzle Pressure | Approximate Abrasive Velocity | Approximate Efficiency Factor |

| 100 psi | 675 kph (422 mph) | 100% |

| 95 psi | 640 kph (400 mph) | 93% |

| 90 psi | 585 kph (366 mph) | 86% |

| 85 psi | 530 kph (331 mph) | 80% |

| 80 psi | 495 kph (309 mph) | 74% |

| 75 psi | 450 kph (281 mph) | 69% |

| 70 psi | 420 kph (263 mph) | 64% |

| Sandblasting Hose Selection Guide for Blasting at 100 psi Nozzle Pressure | |||||

| Nozzle Number | No. 4 | No. 5 | No. 6 | No. 7 | No. 8 |

| Nozzle Size | 1/4” (6 mm) | 5/16” (8 mm) | 3/8” (10 mm) | 7/16” (11 mm) | 1/2” (13 mm) |

| CFM at 100 psi | 103 | 158 | 229 | 312 | 407 |

| Air Hose ID – minimum | 25 mm (1”) | 38 mm (1 1/2”) | 38 mm (1 1/2”) | 50 mm (2”) | 50 mm (2”) |

| Blast Hose ID – minimum | 20 mm (¾”) | 25 mm (1”) | 32 mm (1 1/4”) | 32 mm (1 1/4”) | 38 mm (1 1/2”) |

| Typical ID – OD Relationship in Common Sandblast Hose | |||||||

| Standard Hose | Supa/Whip Hose | ||||||

| ID | OD | ID | OD | ||||

| mm | inch | mm | inch | mm | inch | mm | inch |

| 13 | 1/2” | 33 | 1 5/16” | 13 | 1/2” | 30 | 1 3/16” |

| 19 | ¾” | 40 | 1 1/2” | 19 | ¾” | 33 | 1 5/16” |

| 25 | 1 | 48 | 1 ⅞” | 25 | 1 | 40 | 1 1/2” |

| 32 | 1 1/4” | 55 | 1 5/32” | 32 | 1 1/4” | 48 | 1 ⅞” |

| 38 | 1 1/2” | 60 | 2 ⅜” | 38 | 1 1/2” | 55 | 2 5/32” |

| English USA Units/Metric Conversion Chart | |||

| 1 3/6” | 5 mm | 1 1/4” | 32 mm |

| 1/4” | 6 mm | 5/6” | 33 mm |

| 5/16” | 8 mm | 1-1/2” | 38 mm |

| 3/8” | 10 mm | 1 9/16” | 40 mm |

| 7/16” | 11 mm | 1 3/4” | 44 mm |

| 1/2” | 13 mm | 1 7/8” | 48 mm |

| 5/8” | 16 mm | 2” | 51 mm |

| 3/4” | 19 mm | 2 5/32” | 55 mm |

| 1” | 25 mm | 2 3/8” | 60 mm |

| 1 3/16” | 30 mm | 2 1/2” | 64 mm |

What Size Air Hose for Sandblasting?

Choosing the right air hose size for sandblasting is essential for efficient operation and consistent blasting performance. The hose diameter and length directly impact air pressure, flow rate, and the effectiveness of your sandblasting equipment. Selecting the correct hose ensures smooth abrasive delivery and prevents clogging.

- 3/8-inch Air Hose: Ideal for light-duty sandblasting and small portable units. We recommend this size for projects with minimal abrasive demand, where maneuverability is crucial. It provides sufficient airflow for small nozzles while keeping the hose flexible and easy to handle over short distances.

- 1/2-inch Air Hose: Best suited for medium-duty sandblasting. We provide this size for applications requiring a balance between airflow and reach. It maintains steady pressure, supports standard blasting nozzles, and reduces friction loss, ensuring consistent abrasive flow and effective surface cleaning.

- 3/4-inch Air Hose: Perfect for heavy-duty or commercial sandblasting tasks. We offer this hose for high-volume abrasive blasting, where long hose runs or large nozzles are used. Its larger diameter minimizes pressure drop, maximizes airflow, and ensures optimal performance for demanding projects.

- Hose Length Considerations: Longer hoses can cause significant pressure loss. We advise keeping the hose as short as practical, using larger diameters for extended runs. This ensures your sandblasting equipment operates efficiently, with consistent abrasive delivery and reduced wear on compressors and hoses.

- Nozzle Orifice Size: The size of your nozzle is the most important factor. For example, a 1/4-inch nozzle should be paired with at least a 1-inch inner diameter air hose to maintain pressure.

- Air Compressor CFM: The CFM output of your air compressor must match the requirements of your nozzle. A larger air hose helps to efficiently deliver the high volume of air required by a larger nozzle.

- Hose Length: The longer the air hose, the greater the pressure loss due to friction. Using a larger diameter hose can help to offset this pressure drop, especially for longer runs.

The ideal air hose size for sandblasting depends on several factors, including:

- Sandblasting gun type: Different guns have varying air requirements.

- Project size and complexity: Larger projects may require a larger hose.

- Distance between air compressor and work area: Longer distances necessitate a larger hose to minimize pressure loss.

- Abrasive material: Some abrasives require higher air pressure, which may necessitate a larger hose.

Common air hose sizes for sandblasting:

- 1/4 inch: Suitable for smaller projects and lighter-duty sandblasting guns.

- 3/8 inch: A versatile size for many sandblasting applications, offering a good balance of flow and portability.

- 1/2 inch: Recommended for larger projects, high-pressure applications, or long distances between the compressor and work area.

General guidelines:

- A 3/8 inch air hose is typically sufficient for most residential or small-scale projects.

- A 1/2 inch hose may be necessary for larger industrial applications or long distances.

- Always consult the manufacturer‘s recommendations for your specific sandblasting gun.

It’s important to avoid using a hose that is too small, as this can lead to:

- Reduced air pressure: Affecting the efficiency of the sandblasting process.

- Increased wear and tear on the hose: Shortening its lifespan.

By choosing the right air hose size, you can ensure optimal performance, efficiency, and safety during your sandblasting projects.

Sandblasting Hose Sizes for Different Applications

Selecting the correct sandblasting hose size is crucial for achieving optimal performance in any blasting project. The hose diameter and length affect air pressure, flow rate, and abrasive delivery. Using the right hose ensures efficient operation, reduces wear on equipment, and provides consistent cleaning results.

- Light-Duty Applications (3/8-inch Hose): We recommend a 3/8-inch hose for small, portable sandblasting tools. It offers easy handling and sufficient airflow for light cleaning or detail work. Its flexibility allows operators to maneuver easily while maintaining steady abrasive flow and preventing nozzle clogging.

- Medium-Duty Applications (1/2-inch Hose): A 1/2-inch hose is ideal for standard sandblasting tasks. We provide this size for general surface preparation, moderate abrasive use, and standard nozzle sizes. It ensures consistent air pressure, reliable abrasive delivery, and efficient cleaning across medium-sized areas.

- Heavy-Duty Applications (3/4-inch Hose): For large-scale or industrial sandblasting, we offer 3/4-inch hoses. They handle high abrasive volumes, support long hose runs, and large nozzles. This size minimizes pressure loss, delivers maximum airflow, and maintains efficiency for heavy-duty blasting tasks or commercial projects.

- Long Hose Runs: Hose length affects blasting performance. We suggest using the shortest practical length or increasing hose diameter for extended runs. This reduces pressure drop, maintains consistent abrasive flow, and protects compressors and equipment from excessive strain during prolonged sandblasting operations.

Removing Rust from a Ship

- Large-scale projects: When removing rust from a large ship, a 1/2 inch or even 3/4 inch hose is necessary to handle the high volume of air and abrasive material required for efficient cleaning. These larger hoses can deliver more powerful blasts, accelerating the rust removal process and ensuring thorough coverage of the entire ship’s surface.

- Considerations: Factors such as the ship’s size, the extent of rust damage, and the desired level of surface preparation will influence the optimal hose size. It’s also essential to consider the length of the hose, as longer hoses may experience pressure loss.

Cleaning Smaller Metal Objects

- Smaller objects: For cleaning smaller metal objects like tools or machinery parts, a 1/4 inch or 3/8 inch hose is typically sufficient. These smaller hoses are more maneuverable and easier to handle in confined spaces. They also provide a more controlled blast, making them suitable for delicate or intricate work.

- Considerations: The size and shape of the object, the type of rust or corrosion, and the desired level of surface finish will influence the appropriate hose size.

Removing Paint from Concrete

- Concrete removal: When removing paint from concrete surfaces, a 3/8 inch or 1/2 inch hose can be effective. These hoses provide a powerful blast that can efficiently strip away paint layers.

- Considerations: The thickness of the paint layer, the type of paint, and the condition of the concrete surface will influence the optimal hose size.

Sandblasting Glass or Ceramic

- Delicate materials: For more delicate materials like glass or ceramic, a 1/4 inch hose might be preferable to avoid excessive force that could damage the surface. A smaller hose provides a more controlled blast, reducing the risk of damaging the material.

- Considerations: The thickness and fragility of the glass or ceramic, the desired level of surface preparation, and the type of abrasive used will influence the appropriate hose size.

Remember to always consult the manufacturer‘s recommendations for your specific sandblasting gun and application. By selecting the appropriate hose size, you can ensure optimal performance, efficiency, and safety during your sandblasting projects.

Conclusion

Choosing the correct sandblasting hose size is not merely a technical detail; it’s a critical decision that directly impacts the efficiency, safety, and profitability of your blasting operations. A correctly sized hose prevents significant pressure drop, leading to a powerful, consistent blast and more efficient work.

Ultimately, a perfectly sized hose is an investment in both performance and safety. It ensures high-pressure air and abrasive media are delivered to the nozzle without losing force. Taking the time to select the right hose will lead to improved productivity, reduced media consumption, and a longer lifespan for your equipment.

For professionals demanding the best, having a reliable supplier is key. At Kingdaflex, we offer high-quality wholesale sandblast hoses in all sizes. Our hoses are engineered for maximum abrasion resistance and durability, ensuring a powerful, consistent blast. Contact us today for your next project.