-

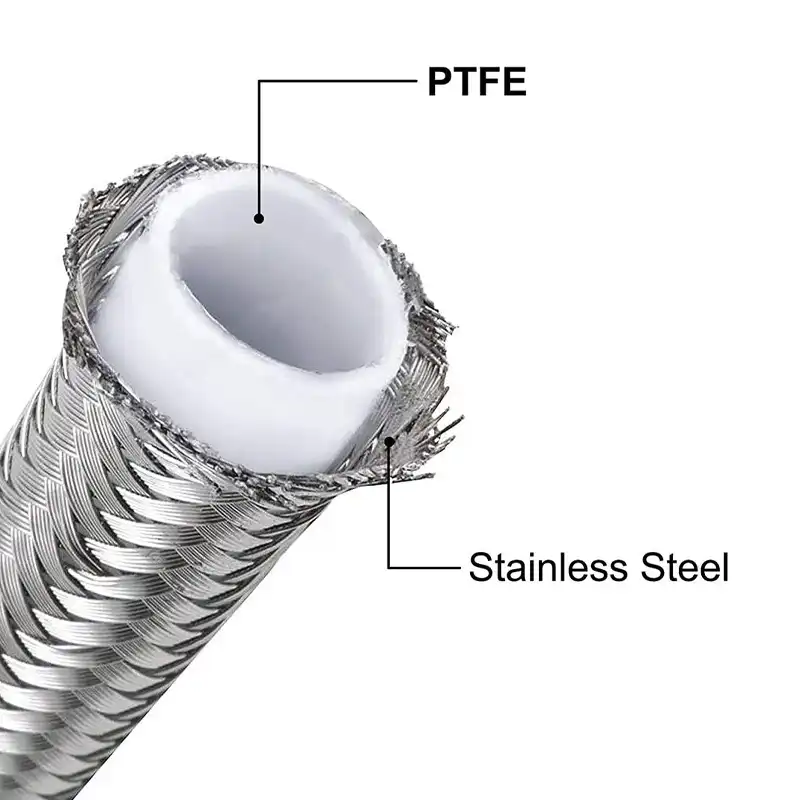

Extrusion of PTFE tube – We extrude pure PTFE into a smooth inner tube, ensuring consistent thickness, chemical resistance, and flexibility for optimal fluid flow.

-

Reinforcement application – We wrap the PTFE tube with stainless steel braid or spiral wire to provide high-pressure resistance, durability, and structural strength for demanding applications.

-

Shaping and curing – We shape the hose to the required diameter and length, then cure it to enhance flexibility, dimensional stability, and long-term reliability.

-

Fitting attachment – We attach customized end fittings, flanges, or adapters to ensure leak-free connections and seamless integration with hydraulic or chemical systems.

-

Quality testing – We perform pressure, flexibility, and chemical compatibility tests to guarantee that every PTFE hose meets stringent safety and performance standards.