Get premium thermoplastic hydraulic hoses directly from China, where we specialize in producing high-quality, lightweight, and durable fluid power solutions. Our advanced manufacturing processes and stringent quality control ensure you receive products that deliver exceptional performance while offering significant cost advantages for your business.

Cost-Effective Manufacturing: Benefit from competitive pricing on bulk and custom orders without sacrificing quality.

Superior Durability: Our hoses are made with high-grade thermoplastic materials that resist abrasion, ozone, and a wide range of chemicals.

Flexible & Lightweight Design: The non-metallic construction makes these hoses easy to handle and install, ideal for applications where weight is a critical factor.

Broad Application Range: Our hoses are suitable for a variety of industries, including construction, agriculture, and high-pressure fluid transfer systems.

As a leading thermoplastic hydraulic hose manufacturer in China, we offer superior fluid power solutions. Our products are engineered for exceptional performance, featuring a lightweight design, high flexibility, and excellent resistance to abrasion and chemicals. We combine state-of-the-art manufacturing with competitive pricing to provide high-quality hoses that meet global standards.

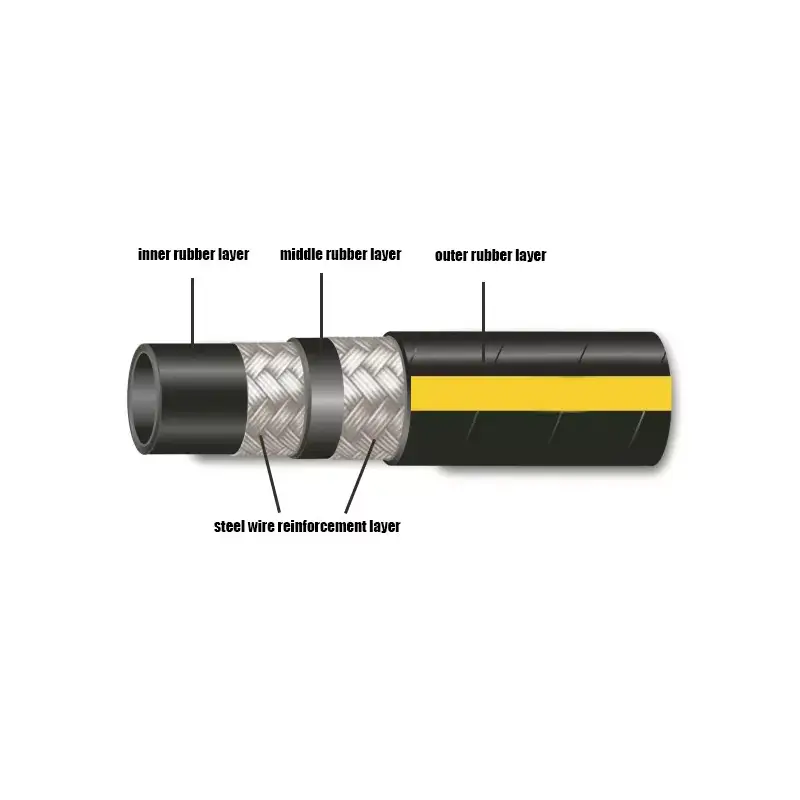

Inner Tube: This innermost layer is typically made from a high-quality, seamless thermoplastic material, such as nylon or polyester, chosen for its excellent chemical compatibility and resistance to the hydraulic fluid it contains.

Reinforcement: Instead of steel wire, the middle layer is a braid or spiral of synthetic fibers, such as polyester, aramid, or carbon fiber. This reinforcement provides the hose with its high pressure rating without adding significant weight or conductivity.

Outer Cover: The outermost layer is a durable thermoplastic material, often polyurethane or another engineered polymer. This cover protects the hose from external elements, including abrasion, UV radiation, ozone, and harsh weather conditions.

Lighter Weight and Flexibility: Thermoplastic hoses are significantly lighter than rubber hoses, making them easier to handle, transport, and install. Their superior flexibility allows for a tighter bend radius, enabling them to be routed in confined or complex spaces.

Superior Abrasion Resistance: The tough polyurethane or other thermoplastic outer covers are highly resistant to abrasion, cuts, and wear from environmental factors, extending the hose’s service life in demanding conditions.

Unlimited Shelf Life: Unlike rubber hoses that can degrade from UV exposure and ozone, thermoplastic hoses have an unlimited shelf life, preventing premature failure and reducing the risk of a “shelf-life” expiration.

Enhanced Chemical and Contamination Resistance: The inner tube is made of non-porous thermoplastic materials that are resistant to a wide variety of hydraulic fluids, including synthetics and solvents, ensuring system cleanliness and preventing fluid permeation.

Non-Conductive Properties: When reinforced with synthetic fibers instead of metal, these hoses provide excellent electrical insulation, which is a critical safety feature for aerial lifts and other equipment used near live electrical sources.

We manufacture a full range of thermoplastic hydraulic hoses designed for exceptional performance and durability. Our hoses are lightweight, highly flexible, and resistant to abrasion and chemicals, making them ideal for a variety of applications. We combine advanced manufacturing processes with rigorous quality control to ensure every hose meets the highest standards.

We offer 100R7 thermoplastic hose for medium-pressure hydraulic systems. It features a seamless thermoplastic inner tube and a single or double braided synthetic fiber reinforcement. Ideal for aerial lifts and industrial machinery, this hose provides excellent electrical non-conductivity and superior flexibility for tight routing.

We offer high-pressure SAE 100R8 hoses for demanding hydraulic applications. With a robust thermoplastic inner tube and high-tensile aramid fiber reinforcement, this hose can withstand higher pressures than the 100R7 type. It is commonly used in heavy construction and mining equipment.

We offer this advanced hose, which is a recent addition to the SAE J517 standard. The SAE 100R18 is designed for compact, high-pressure applications where a tight bend radius is essential. Its unique construction provides the same working pressure as the 100R8 hose but with a smaller outer diameter.

Navigating the complexities of hydraulic systems requires a tailored approach. When you need a thermoplastic hydraulic hose for a specific application, we can help you customize it to meet your exact safety and performance requirements. We’ll work with you to select the ideal specifications for your project, ensuring a perfect fit and dependable operation.

We manufacture our thermoplastic hoses to your precise length specifications, ensuring a perfect fit and eliminating waste. We offer a variety of inner and outer diameters to match your flow requirements, allowing for optimized system efficiency and performance in any application.

We can tailor the hose’s reinforcement layers to meet your exact pressure needs. By adjusting the number and type of synthetic fiber braids, we deliver a hose that handles your required working pressure and burst pressure without adding unnecessary weight or rigidity.

We can design and manufacture hoses that comply with specific industry standards beyond the standard SAE ratings. This includes options that are fire-resistant, suitable for food and beverage applications, or designed for specific chemical or high-temperature environments.

We offer multiple outer cover options, including high-abrasion-resistant polyurethane or specialized materials for chemical exposure. We can also provide a range of colors for easy system identification and safety coding on your equipment.

A thermoplastic hydraulic hose is a lightweight and flexible hose designed for hydraulic systems, made from synthetic polymers. Unlike traditional rubber hoses that use steel wire reinforcement, thermoplastic hoses are constructed with a non-metallic, synthetic fiber reinforcement (such as polyester or aramid) that provides high pressure ratings without adding significant weight.

This construction allows for a smaller outer diameter and a tighter bend radius, making them ideal for applications with limited space. Due to their material composition, these hoses also offer excellent resistance to abrasion, ozone, and many chemicals, and can be engineered to be non-conductive for electrical safety.

A thermoplastic hydraulic hose is a lightweight and flexible hose made from synthetic polymers and fibers instead of traditional rubber and steel. Its construction is designed for high performance while minimizing weight and allowing for a tight bend radius. This unique composition also provides superior resistance to abrasion and environmental factors.

Thermoplastic Hydraulic Hose Structure

Inner Tube: This core layer is typically made of a smooth, seamless thermoplastic material like nylon, polyester, or polyurethane, chosen for its compatibility with a wide range of hydraulic fluids.

Reinforcement: Instead of steel wire, this layer uses one or more braids of high-tensile strength synthetic fibers, such as polyester or aramid, which provide the hose’s pressure rating and flexibility.

Outer Cover: The outermost layer is made of a durable thermoplastic like polyurethane to protect the hose from external damage, including abrasion, UV rays, and chemicals.

A thermoplastic hydraulic hose is a lightweight and highly versatile component used in a wide range of industries where the demands of the application go beyond what traditional rubber hoses can provide. Its unique construction with a thermoplastic inner tube and synthetic fiber reinforcement makes it ideal for applications that require flexibility, a small bend radius, and superior resistance to abrasion and environmental factors. Its non-conductive properties are a key safety feature in many of its applications.

Common Thermoplastic Hose Uses and Industries

Aerial Lifts and Scissor Lifts: Used for their non-conductive properties to protect workers operating near high-voltage power lines.

Forklifts and Material Handling: The hoses’ flexibility and durability are essential for mast and pulley systems that require continuous movement and high-pressure fluid transfer.

High-Pressure Hydraulic Tools: Utilized in hydraulic rescue tools (e.g., the “Jaws of Life”) and other portable equipment where a lightweight and durable hose is critical for operator safety and efficiency.

Construction and Agriculture: Commonly found on heavy machinery and agricultural equipment where they must withstand abrasion, chemicals, and extreme weather conditions.

Marine Steering: Their resistance to saltwater and corrosion makes them an excellent choice for marine applications.

Water Jetting and Cleaning: Their high pressure rating and resistance to water make them ideal for industrial cleaning and cutting applications.

There are several types of thermoplastic hydraulic hoses, which are generally categorized by their pressure rating and construction as defined by the SAE J517 standard.

While the standard includes many types of hoses, the most common thermoplastic variations are R7 and R8.

SAE 100R7 is a medium-pressure thermoplastic hose. It’s designed for applications where electrical non-conductivity is crucial, using a single or double synthetic fiber braid for reinforcement. It’s often used on aerial lifts and cherry pickers.

SAE 100R8 is a high-pressure thermoplastic hose. It’s built with more robust synthetic fiber reinforcement, often aramid, to handle higher pressures. It’s a lightweight alternative to traditional high-pressure rubber hoses.

SAE 100R18 is a compact, high-pressure thermoplastic hose.3 This type offers the same working pressure as 100R8 but with a smaller outer diameter and a tighter bend radius, making it ideal for confined spaces.

You should choose our thermoplastic hydraulic hoses for their unique blend of superior performance and safety. We use high-quality, advanced thermoplastic polymers and synthetic fiber reinforcement to create hoses that are not only exceptionally durable and lightweight but also highly flexible.

This ensures they can withstand demanding conditions while being easy to install and handle. Our hoses are engineered to provide reliable performance and a long service life, giving you a cost-effective solution without compromising on quality or safety.

Exceptional Durability: Our hoses feature a tough outer cover that resists abrasion, ozone, and UV light, extending their lifespan in harsh environments.

Lightweight and Flexible: The thermoplastic construction makes them significantly lighter and easier to route in tight spaces compared to traditional hoses.

High Chemical Resistance: The non-porous inner tube is compatible with a wide range of hydraulic fluids, preventing contamination and ensuring system longevity.

Non-Conductive Options: We offer hoses with non-conductive properties, providing a critical layer of safety for operators working near electrical sources.