Hydraulic cylinders are the unsung heroes of countless industries, silently powering everything from construction equipment to manufacturing machinery. These robust devices are fundamental components in any hydraulic system, expertly converting the energy of pressurized hydraulic fluid into linear mechanical force and motion. Understanding their function is key to appreciating modern industrial capabilities.

This guide will delve into the fascinating world of hydraulic cylinders, demystifying their internal workings, diverse types, and widespread applications. Whether you’re an industry professional, an engineering student, or simply curious about how heavy machinery operates, this ultimate guide will provide comprehensive insights into these indispensable components.

What is a Hydraulic Cylinder?

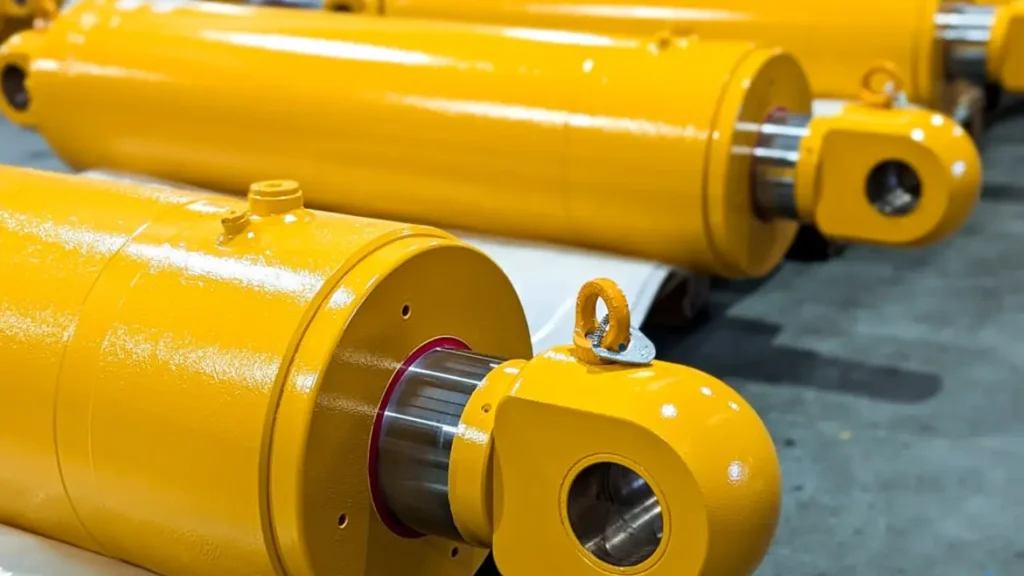

A hydraulic cylinder is a mechanical actuator that converts hydraulic energy—derived from pressurized hydraulic fluid, typically oil—into linear mechanical force and motion. It essentially functions as the “muscle” of a hydraulic system.

Consisting of a cylinder barrel, a piston, and a piston rod, the cylinder operates by having hydraulic fluid pumped into one side of the piston, which then pushes the piston and its attached rod, creating powerful linear movement.

This ability to generate immense force makes hydraulic cylinders indispensable components in a vast array of applications, including heavy construction equipment, manufacturing machinery, and various lifting and pressing systems.

Components of Hydraulic Cylinder

A hydraulic cylinder is comprised of several key components that work in unison to generate linear force and motion. These essential parts include:

- Cylinder Barrel: The main body that houses all internal components and contains the pressurized hydraulic fluid.

- Piston: A disc-shaped component that moves within the barrel, separating pressure zones and translating hydraulic pressure into mechanical force.

- Piston Rod: A robust shaft attached to the piston, extending outside the cylinder to transfer the generated force to the external load.

- Cylinder Head (Rod End): The end cap where the piston rod exits the cylinder, containing seals to prevent fluid leakage around the rod.

- Cylinder Base (Cap End): The opposite end cap that encloses the pressure chamber.

- Seals and Glands: Critical elements, usually made of rubber or other elastomers, that prevent fluid leakage and maintain pressure within the cylinder, ensuring efficient operation.

- Ports: Inlets and outlets on the cylinder through which hydraulic fluid enters and exits, controlling the piston’s movement.

How Does a Hydraulic Cylinder Work

A hydraulic cylinder operates on Pascal’s Principle, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel. In a hydraulic cylinder:

- Fluid Input: Hydraulic fluid, typically oil, is pumped into one of the cylinder’s ports, usually by a hydraulic pump.

- Pressure Application: As the incompressible fluid fills the chamber, it exerts pressure uniformly against the piston’s surface.

- Piston Movement: This pressure, multiplied by the piston’s surface area, generates a linear force that pushes the piston and its attached rod.

- Force Transmission: The movement of the piston rod then transfers this mechanical force to the external load or machinery, enabling tasks like lifting, pushing, or pulling.

- Fluid Return (Double-Acting): In double-acting cylinders, fluid can be directed to either side of the piston, allowing for controlled extension and retraction. For single-acting cylinders, a spring or external force is often used for the return stroke.

Types of Hydraulic Cylinders

Hydraulic cylinders come in various designs, each tailored for specific applications and operational needs. Understanding the different types is essential for selecting the right cylinder for optimal performance and efficiency in any given hydraulic system.

Single-Acting Hydraulic Cylinders

Single-acting hydraulic cylinders are designed to apply force in only one direction. They typically have a single port for hydraulic fluid to enter, extending the piston rod. The retraction of the rod usually relies on an external force, such as the weight of the load or a return spring integrated within the cylinder. These are simpler in design and often used in applications where a controlled return stroke is not critical, like lifting operations where gravity assists retraction.

Double-Acting Hydraulic Cylinders

Double-acting hydraulic cylinders are capable of producing force and movement in both directions, extending and retracting the piston rod. They feature two ports, one at each end of the cylinder barrel. By directing hydraulic fluid to one port, the piston extends, and by directing it to the other, the piston retracts. This bi-directional capability offers greater control and versatility, making them the most common type used in machinery requiring precise push-and-pull operations, such as excavators and presses.

Telescopic Hydraulic Cylinders

Telescopic hydraulic cylinders, also known as multi-stage cylinders, are designed to provide a much longer stroke length compared to their retracted length. They consist of a series of nested tubes of progressively smaller diameters, which extend like a telescope. When hydraulic fluid is introduced, these stages extend one after another, offering an impressive reach from a compact initial size. They are widely used in applications where a long stroke is needed but mounting space is limited, such as dump trucks, cranes, and platform lifts.

Tie-Rod Hydraulic Cylinders

Tie-rod hydraulic cylinders are characterized by their construction, where the end caps are secured to the cylinder barrel by external tie rods. These rods run the full length of the cylinder and are tightened with nuts, providing the necessary strength to contain high internal pressures. This design allows for easier maintenance and disassembly compared to other types. They are commonly found in industrial applications where robustness and serviceability are key, offering reliable performance in demanding environments.

Welded Body Hydraulic Cylinders

Welded body hydraulic cylinders, as their name suggests, have their end caps permanently welded to the cylinder barrel. This construction creates a more compact and sturdy design, as there are no external tie rods. The welded joints provide excellent structural integrity, making them suitable for heavy-duty applications where shock and vibration are common. They are often preferred in mobile equipment like construction machinery and agricultural vehicles due to their robust and space-efficient build.

How to Measure Hydraulic Cylinder?

Accurately measuring a hydraulic cylinder is crucial for replacement, repair, or system design. Precise dimensions ensure compatibility and optimal performance.

This section outlines the essential measurements and the steps involved to correctly size a hydraulic cylinder for any application.

Step 1: Bore Diameter Measurement

The bore diameter refers to the internal diameter of the cylinder barrel. This measurement is critical as it directly influences the cylinder’s force output; a larger bore generates more force at the same pressure.

To measure the bore, you would typically measure the inside diameter of the cylinder tube. This can be done with calipers or an internal micrometer, ensuring you get the most accurate reading of the cylinder’s internal width.

Step 2: Rod Diameter Measurement

The rod diameter is the external diameter of the piston rod. This dimension is important for determining the rod’s strength and compatibility with various rod end attachments and seals.

Measure the exposed part of the piston rod using calipers or a micrometer. Take several measurements along the rod to account for any potential wear and ensure a consistent and accurate reading of its thickness.

Step 3: Stroke Length Measurement

The stroke length is the maximum distance the piston rod can travel from its fully retracted to its fully extended position. This measurement dictates the range of motion the cylinder can provide for an application.

To determine the stroke length, measure the distance from the face of the rod end gland to the center of the rod eye when the cylinder is fully retracted, then again when fully extended. The difference between these two measurements is the stroke.

Step 4: Retracted Length Measurement

The retracted length, also known as the closed center length, is the total length of the cylinder when the piston rod is fully retracted. This measurement is crucial for fitting the cylinder into specific spaces.

Measure from the center of the mounting pin hole at the rod end to the center of the mounting pin hole at the cap end when the cylinder is completely closed. This provides the overall compact length.

Step 5: Pin Diameter Measurement

Pin diameter refers to the diameter of the mounting pins used to connect the cylinder to its application. These dimensions are vital for ensuring proper fit and secure attachment.

Measure the diameter of the holes at both the rod end and the cap end mounts where the pins would pass through. This ensures that the correct size pins can be used for secure and stable mounting.

Tips of Fixing Hydraulic Cylinders

Regular maintenance and prompt troubleshooting are vital for extending the lifespan and ensuring the efficient operation of hydraulic cylinders. Addressing issues early prevents minor problems from escalating into costly repairs or system failures.

- Regular Visual Inspections: Consistently check for any signs of external leakage around seals, especially rod seals, and ports. Look for visible damage like dents, scratches, or corrosion on the cylinder barrel and piston rod. Early detection of leaks or damage can prevent further fluid contamination and system degradation, saving significant repair costs.

- Fluid Contamination Control: Hydraulic fluid contamination (by dirt, water, or air) is a leading cause of cylinder failure. Regularly check fluid levels, ensure the fluid is clean and at the correct viscosity, and verify that filters and breathers are properly maintained and replaced as needed. Clean fluid prevents abrasive wear on internal components and preserves seal integrity, prolonging cylinder life.

- Addressing Cylinder Drift: If a cylinder “drifts” or fails to hold its position under load, it often indicates internal leakage, commonly due to worn piston seals or a faulty holding valve. This issue can compromise safety and efficiency. A pressure test can confirm internal leaks, necessitating seal replacement to restore the cylinder’s holding capacity and prevent unexpected movement.

- Piston Rod Inspection: The piston rod is highly susceptible to external damage. Regularly inspect it for scratches, pitting, or bending, which can quickly lead to seal failure and external leaks. Minor imperfections might be polished, but significant damage or bends often require rod replacement to prevent further damage to internal seals and ensure smooth operation.

- Bleeding Air from the System: Trapped air within the hydraulic system can cause erratic or “spongy” cylinder movement, noise, and reduced force output. Bleeding the system involves cycling the cylinder through its full stroke multiple times and opening bleed valves, if present, to expel air. Proper bleeding ensures smooth, consistent operation and maximum power delivery.

Conclusion

In conclusion, hydraulic cylinders are indispensable workhorses, central to the functionality of countless hydraulic systems across diverse industries. We’ve explored their fundamental components, the principles behind their powerful operation, and the various types tailored for specific applications. Their ability to deliver immense linear force makes them critical for everything from lifting heavy loads to precise material handling.

Mastering the intricacies of hydraulic cylinders—from their design variations to proper maintenance—is crucial for optimizing performance, ensuring safety, and extending the lifespan of machinery. Regular inspection and timely replacement of worn components are vital to prevent costly downtime and operational inefficiencies. Their continued evolution promises even greater efficiency and power in future industrial applications.

For all your hydraulic cylinder needs, including high-quality wholesale hydraulic cylinder hoses, look no further than Kingdaflex. We provide durable and reliable solutions designed to meet the rigorous demands of any hydraulic system, ensuring your operations run smoothly and efficiently. Trust Kingdaflex for superior hydraulic components.