When it comes to safe driving, the braking system of a vehicle plays a crucial role. As a driver, it is essential to ensure that all components of the braking system are in good working condition.

The air brake hose is one such component that is often overlooked but plays a significant role in the braking system. In this article, we will explore everything you need to know about air brake hoses, including their functions, types, and maintenance.

What Is An Air Brake Hose?

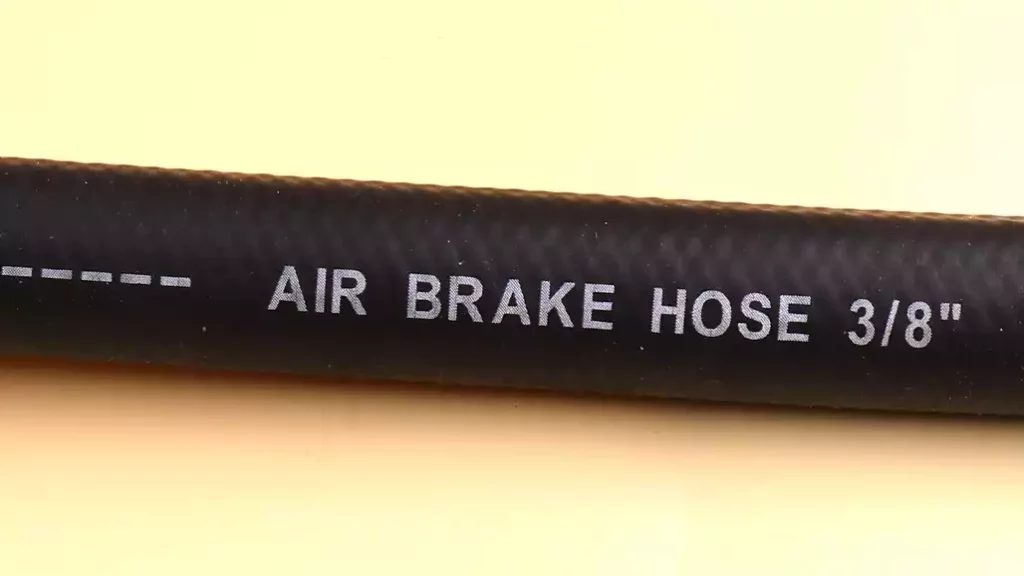

An air brake hose is a component of the air brake system in heavy-duty vehicles such as trucks and buses. It is responsible for transmitting compressed air from the brake system’s air tanks to the brake chambers, which activate the brakes.

What Is Air Brake Hose Made of?

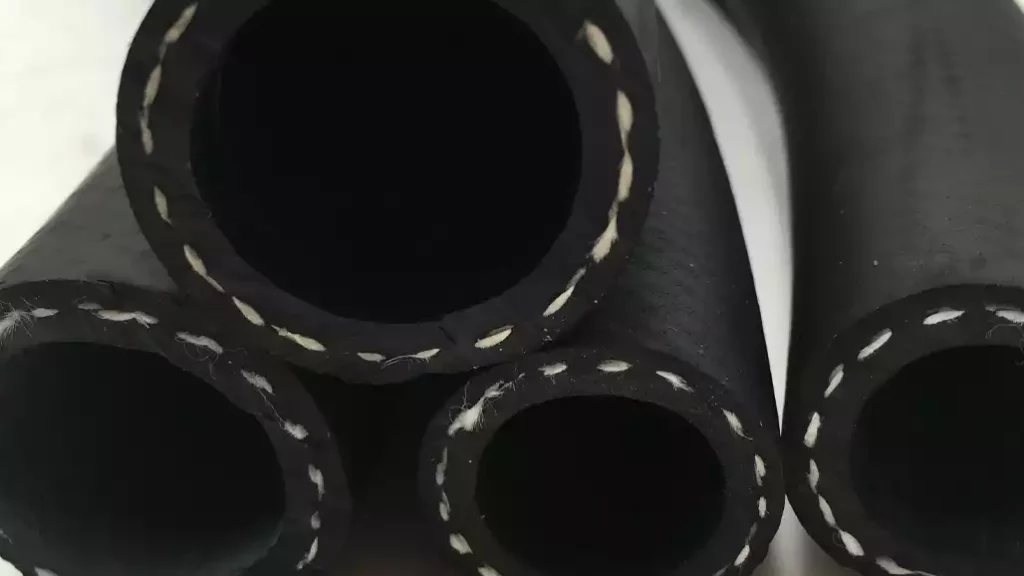

An air brake hose is typically made of synthetic rubber, which is reinforced with layers of braided or spiral-wound fibers to withstand the high pressures and temperatures of compressed air.

The synthetic rubber used in air brake hoses is specially formulated to resist abrasion, heat, and ozone, which can cause the hose to crack or deteriorate over time. Some air brake hoses may also have an outer cover made of elastomeric material to protect against external damage and extend the hose’s lifespan.

Air brake hoses are designed to be durable and long-lasting to ensure the optimal performance and safety of the vehicle’s braking system.

How Does An Air Brake Hose Work?

The air brake system works on the principle of using compressed air to actuate the brakes. When the driver presses the brake pedal, it sends a signal to the air compressor to generate compressed air, which is then sent through the air brake hose to the brake chamber.

The air pressure in the brake chamber then causes the brake shoes or pads to press against the brake drum or rotor, thereby slowing down or stopping the vehicle.

Types of Air Brake Hoses

There are three types of air brake hoses:

Rubber Air Brake Hose

Rubber air brake hoses are the most common type of air brake hose used in heavy-duty vehicles. They are made of synthetic rubber and are designed to withstand high-pressure air flow. Rubber air brake hoses are flexible, durable, and resistant to heat, abrasion, and ozone.

Nylon Air Brake Hose

Nylon air brake hoses are lighter and more flexible than rubber hoses, making them easier to handle and install. They are made of nylon and are designed to withstand high-pressure air flow. Nylon air brake hoses are also resistant to abrasion, heat, and chemicals.

Teflon Air Brake Hose

Teflon air brake hoses are the most expensive type of air brake hose but are also the most durable. They are made of Teflon and are designed to withstand high temperatures and pressures. Teflon air brake hoses are also resistant to chemicals and abrasion.

How to Choose the Right Air Brake Hose?

When choosing an air brake hose, it is essential to consider the following factors:

- Hose material: Choose a hose that is suitable for the type of vehicle and the conditions in which it will be used.

- Hose size: Choose a hose that is compatible with the brake system of your vehicle.

- Working pressure: Choose a hose that can handle the working pressure of your vehicle’s brake system.

- Burst pressure: Choose a hose that can handle the maximum pressure that may be encountered in the brake system.

- Length: Choose a hose that is long enough to reach all components of the brake system.

Installation of Air Brake Hose

Proper installation of the air brake hose is crucial to ensure its optimal performance and safety. Here are some steps to follow when installing an air brake hose:

- Ensure that the brake system is depressurized before installation.

- Choose the appropriate size and type of hose for the vehicle.

- Cut the hose to the required length.

- Use the appropriate fittings and connectors for the hose.

- Make sure that all fittings are tightened to the recommended torque.

- Use a wrench to tighten the fittings and ensure they are snug.

- Install a strain relief device to prevent the hose from kinking or twisting.

- Secure the hose with clamps or brackets to prevent it from moving or rubbing against other components.

- Test the brake system for leaks or other issues.

Maintenance of Air Brake Hose

Proper maintenance of the air brake hose is essential to ensure its longevity and safety. Here are some tips for maintaining the air brake hose:

- Check the air brake hose regularly for signs of wear, damage, or leaks.

- Replace the air brake hose if it is cracked, swollen, or shows any signs of damage.

- Clean the air brake hose regularly to remove dirt, grime, and other debris.

- Keep the air brake hose away from sources of heat, chemicals, and other hazards.

- Lubricate the fittings and connectors regularly to prevent corrosion and ensure a tight seal.

- Check the strain relief device regularly to ensure that it is in good condition.

- Test the brake system regularly to ensure that it is functioning properly.

Signs of a Failing Air Brake Hose

It is essential to recognize the signs of a failing air brake hose to prevent accidents and ensure safety on the road. Here are some signs that indicate a failing air brake hose:

- Spongy or soft brake pedal.

- Brakes that do not respond or have reduced braking power.

- Air leaks from the brake system.

- Sudden loss of brake pressure.

- Unusual noises from the brake system.

Tips to Extend the Life of Air Brake Hose

Here are some tips to extend the life of the air brake hose:

- Keep the air brake hose clean and free of debris.

- Store the air brake hose in a dry, cool place away from direct sunlight and other hazards.

- Inspect the air brake hose regularly and replace it if necessary.

- Use the appropriate fittings and connectors for the hose.

- Use a strain relief device to prevent the hose from kinking or twisting.

- Test the brake system regularly to ensure that it is functioning properly.

Safety Measures for Air Brake Hose

To ensure safety on the road, it is essential to follow these safety measures for air brake hoses:

- Ensure that the brake system is depressurized before working on the air brake hose.

- Use the appropriate personal protective equipment when working on the brake system.

- Use only recommended hoses, fittings, and connectors for the brake system.

- Ensure that the air brake hose is properly installed and secured.

- Test the brake system regularly to ensure that it is functioning properly.

Benefits of Air Brake Hose

Here are some benefits of using air brake hoses:

- Reliable and efficient braking system.

- Long-lasting and durable.

- Resistant to heat, abrasion, and other hazards.

- Easy to install and maintain.

- Compatible with different types of vehicles.

Difference Between Air Brake Hose and Hydraulic Brake Hose

Air brake hoses and hydraulic brake hoses are both used in braking systems, but there are some key differences between them. Air brake hoses use compressed air to actuate the brakes, while hydraulic brake hoses use hydraulic fluid.

Air brake hoses are commonly used in heavy-duty vehicles such as trucks and buses, while hydraulic brake hoses are commonly used in cars and motorcycles. Air brake hoses are also thicker and more durable than hydraulic brake hoses, as they must withstand higher pressures and temperatures.

Additionally, air brake hoses require special fittings and connectors to ensure a tight seal, while hydraulic brake hoses use standard fittings and connectors.

Conclusion

Proper installation, maintenance, and safety measures are essential for the optimal performance and longevity of air brake hoses. Regular inspection and replacement of the air brake hose are necessary to prevent accidents and ensure safety on the road. By following the tips and guidelines outlined in this article, you can ensure the proper functioning of your vehicle’s braking system and prevent potential hazards.