Welcome to the ultimate guide on PVC hoses, your comprehensive resource for understanding these versatile and essential industrial components. In this guide, we’ll delve into the fundamental characteristics of PVC hoses, exploring their composition, key features, and the diverse range of applications they serve across various industries.

We’ll specifically focus on the robust PVC Steel Wire Reinforced Hose, highlighting its unique advantages in terms of durability, flexibility, and resistance. Whether you’re in agriculture, construction, or manufacturing, this guide will equip you with the knowledge to make informed decisions about your hose needs.

What is PVC Hose

A PVC hose is a type of flexible tubing manufactured from polyvinyl chloride (PVC), a synthetic thermoplastic polymer. Known for its versatility, durability, and cost-effectiveness, PVC hoses are widely utilized across numerous industries and everyday applications.

The material can be formulated to achieve various levels of flexibility, and often incorporates reinforcement such as braiding or spiral steel wire to enhance strength, pressure resistance, and vacuum capabilities.

This combination of properties makes PVC hoses suitable for conveying a diverse range of substances, including water, oils, chemicals, air, and various dry materials, making them a popular choice in sectors like agriculture, construction, and manufacturing.

Brief History Of PVC

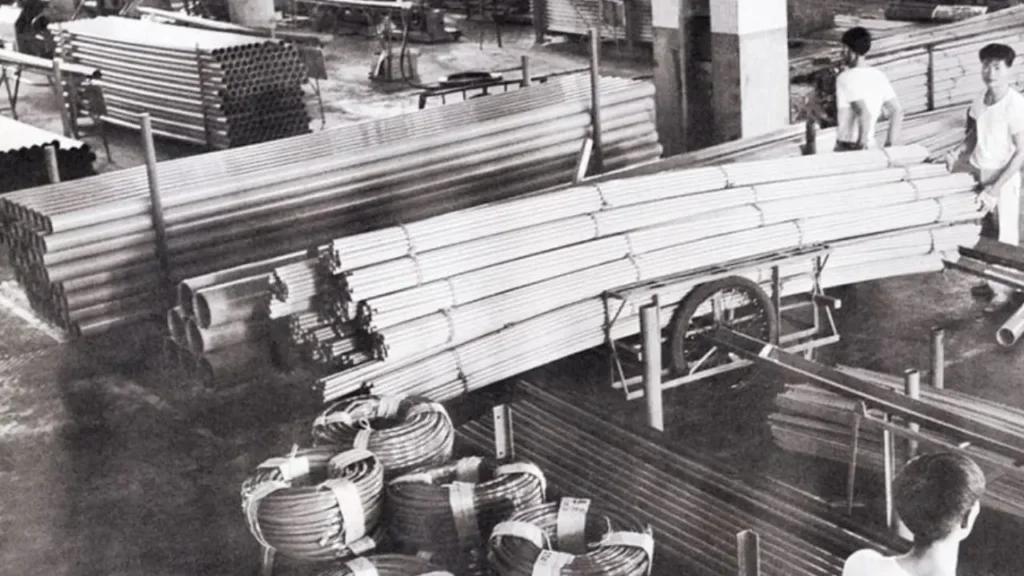

Polyvinyl chloride (PVC) has a fascinating history, starting with accidental discoveries in the 19th century by chemists Henri Victor Regnault in 1835 and Eugen Baumann in 1872. Initially, this white solid remained a laboratory curiosity, deemed difficult to work with and without obvious practical uses.

The first patent for a PVC polymerization method using sunlight was secured in 1913 by German chemist Friedrich Klatte. However, the true turning point came in the 1920s when American scientist Waldo Semon, working for B.F. Goodrich, discovered how to plasticize PVC, making it flexible and workable.

This breakthrough opened the door for its widespread commercial application, especially as a waterproof coating for fabrics during the 1930s and a vital insulator for military ship wiring during World War II, paving the way for its boom in the construction and other industries from the 1950s onwards.

PVC Hose Types

Beyond the general definition, PVC hoses come in various specialized types, each engineered to meet specific application demands. Understanding these distinctions is crucial for selecting the most appropriate hose for your needs, ensuring optimal performance and longevity in diverse environments.

Clear PVC Hose

Clear PVC hoses are characterized by their transparent construction, allowing for visual monitoring of the material flowing through. This feature is particularly beneficial in applications where observing flow, detecting blockages, or identifying the conveyed substance is important. They are often used for general water transfer, low-pressure air lines, and in food and beverage industries, especially when manufactured to be food-grade compliant. Their smooth interior also promotes efficient flow and is easy to clean.

PVC Suction Hose

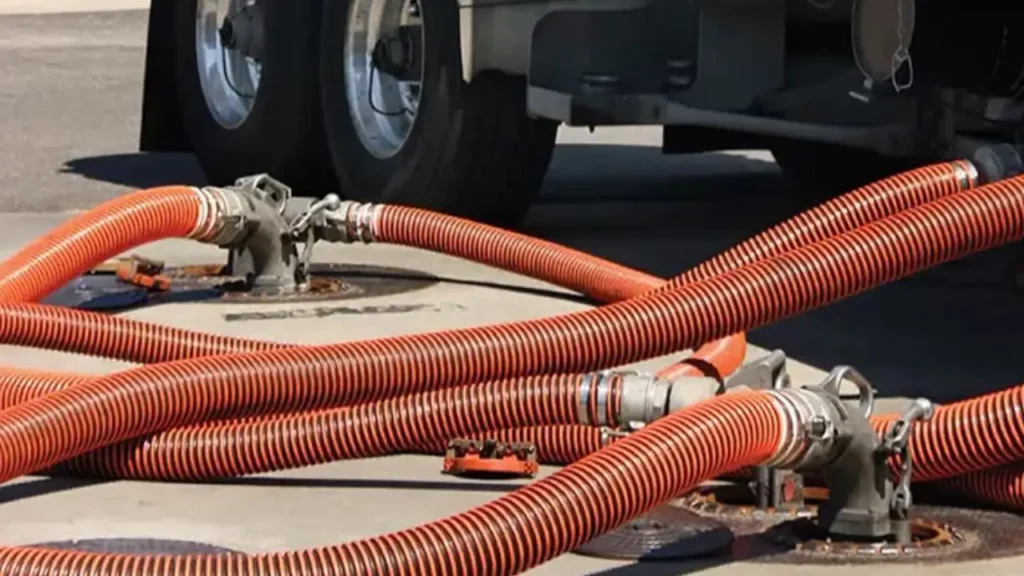

PVC suction hoses are designed with a rigid PVC helix (spiral) embedded within a flexible PVC wall. This robust construction provides excellent vacuum resistance, preventing the hose from collapsing under negative pressure during suction operations. They are commonly employed in agriculture for irrigation, in construction for dewatering, and in industrial settings for conveying abrasive materials, slurries, and water, offering durability against wear and tear.

PVC Layflat Hose

PVC layflat hoses are distinguished by their ability to be rolled flat when not in use, making them highly compact for storage and transportation. They consist of a flexible PVC cover and lining, often with textile reinforcement for added strength, allowing them to handle moderate to high pressures. These hoses are extensively used for water discharge, irrigation, and temporary fluid transfer in agriculture, mining, and construction due to their ease of deployment and retrieval.

PVC Braided Hose

PVC braided hoses feature a multi-layered construction, with a high-strength textile yarn (braid) embedded between layers of flexible PVC. This braiding significantly enhances the hose’s working pressure capabilities and burst resistance compared to unreinforced PVC hoses. They are ideal for applications requiring higher pressure such as air lines, water supply, and general industrial fluid transfer where a balance of flexibility and pressure handling is necessary.

PVC Steel Wire Reinforced Hose

PVC steel wire reinforced hoses integrate a spiral steel wire helix within the PVC wall, providing superior kink resistance, crush proofing, and vacuum capabilities. The steel wire ensures the hose maintains its shape even under severe bending or negative pressure. They are extensively used for heavy-duty suction and discharge of water, oil, chemicals, and abrasive materials in industrial, agricultural, and construction environments here in Qingdao, offering excellent durability and reliability.

What is a PVC Hose Used For?

PVC hoses are highly versatile and are utilized across a vast array of industries and applications due to their beneficial properties like flexibility, durability, and resistance to chemicals and abrasion. They are essentially flexible conduits designed for the efficient transfer of liquids, gases, and various solid materials. Their adaptability, often enhanced by different reinforcement types, makes them suitable for both general-purpose and highly specialized tasks in demanding environments.

Common uses for PVC hoses include:

- Water Transfer: Ideal for irrigation in agriculture, general water supply, garden hoses, and dewatering in construction.

- Fluid & Chemical Handling: Used for conveying a wide range of industrial fluids, mild chemicals, and certain oils.

- Suction and Discharge: Especially reinforced PVC hoses (like steel wire reinforced) are used for drawing liquids and slurries from one point to another.

- Air & Pneumatic Systems: Employed for compressed air lines in workshops, factories, and for powering pneumatic tools.

- Food and Beverage Industry: Food-grade PVC hoses are used for transferring potable water, beverages, and other food products.

- Material Conveyance: Suitable for moving powders, granules, and small solid particles in various manufacturing and processing operations.

- Protective Conduits: Sometimes used as flexible conduits to protect electrical wiring and cables.

PVC Hose Benefits

PVC hoses offer a compelling suite of benefits that make them a preferred choice across numerous industries, especially for businesses operating in Qingdao and globally. Their inherent material properties, combined with various reinforcement options, translate into practical advantages that enhance efficiency, reduce operational costs, and ensure reliable performance in diverse applications.

Here are the key benefits of PVC hoses:

- Exceptional Flexibility: PVC hoses are highly pliable, allowing for easy handling, maneuverability around obstacles, and efficient coiling for storage. This flexibility simplifies installation and reduces physical strain during use, making them user-friendly in various settings.

- Durability and Longevity: Manufactured from robust PVC compounds, these hoses exhibit good resistance to abrasion, tearing, and general wear and tear. This inherent toughness ensures a long service life, even in demanding industrial and outdoor environments, reducing replacement frequency.

- Resistance to Chemicals and Abrasion: Depending on the specific formulation, PVC hoses can resist a wide range of chemicals, oils, and abrasive materials. This chemical inertness prevents degradation and contamination, making them suitable for diverse fluid transfer tasks.

- Cost-Effectiveness: Compared to hoses made from more specialized materials, PVC hoses are generally more affordable to manufacture and purchase. Their combination of performance and economical pricing offers excellent value, making them a budget-friendly solution for many applications.

- Transparency for Visual Monitoring: Many PVC hoses, particularly clear varieties or those with visible reinforcement, allow for visual inspection of the conveyed material. This transparency helps in detecting blockages, monitoring flow rates, and ensuring the correct material is being transferred.

- Good Pressure and Vacuum Capabilities: With various reinforcement options like braiding or steel wire, PVC hoses can be engineered to handle a wide range of working pressures and can effectively resist collapse under vacuum, making them versatile for both suction and discharge applications.

PVC vs Polyurethane Hose

When selecting hoses for various applications, two prominent materials often come into consideration: PVC (Polyvinyl Chloride) and Polyurethane (PU). While both offer flexibility and durability, their distinct properties make them suitable for different operational environments and conveying tasks.

Abrasion Resistance

Polyurethane hoses generally exhibit superior abrasion resistance compared to PVC hoses. This makes PU an excellent choice for applications involving the transfer of abrasive materials like grains, wood chips, slurries, or concrete. PVC, while offering good resistance to many substances, can wear down more quickly when exposed to constant friction from solids.

Flexibility and Kink Resistance

Both materials offer good flexibility, but polyurethane tends to maintain its flexibility better, especially in colder temperatures. PVC can become stiffer and more brittle in cold conditions, making it harder to handle and more prone to kinking. Polyurethane’s natural elasticity also provides excellent kink memory, allowing it to recover its original shape more readily.

Chemical and Oil Resistance

Polyurethane hoses generally offer a broader range of resistance to chemicals, oils, and solvents than PVC hoses. While certain PVC formulations can be made resistant to specific chemicals, PU often performs better against petroleum-based products, making it a preferred choice for fuel lines and applications involving aggressive fluids.

Temperature Range

Polyurethane typically has a wider operating temperature range, performing well in both lower and higher temperatures compared to PVC. PVC can lose flexibility in extreme cold and soften or degrade at higher temperatures. PU’s ability to maintain its integrity across a broader thermal spectrum makes it more versatile for varied climatic conditions.

Cost

PVC hoses are generally more cost-effective to produce and, therefore, more readily available at a lower price point than polyurethane hoses. This makes PVC a popular choice for budget-conscious projects or applications where the extreme performance characteristics of PU are not strictly necessary.

Comparison Table: PVC vs. Polyurethane Hose

| Feature | PVC Hose | Polyurethane (PU) Hose |

| Abrasion Resistance | Good | Excellent (Superior) |

| Flexibility (Cold) | Can stiffen | Maintains flexibility better |

| Chemical/Oil Resist. | Good (varies with formulation) | Excellent (Broader range) |

| Temperature Range | Generally narrower (-20°C to +60°C) | Wider (-40°C to +90°C) |

| Cost | More Cost-Effective | Generally Higher |

| Kink Resistance | Good | Excellent |

Conclusion: Your Go-To for PVC Hose

In conclusion, the PVC Steel Wire Reinforced Hose stands out as a highly adaptable and reliable solution for a multitude of fluid transfer challenges. Its exceptional durability, combined with inherent flexibility and resistance to various elements, makes it an indispensable asset across agriculture, construction, and diverse industrial applications.

Understanding the benefits—from superior kink resistance and visual flow monitoring to chemical resilience and cost-effectiveness—empowers you to select the right hose for optimal performance and longevity. This guide aims to be your definitive resource in navigating the world of PVC hoses, ensuring informed choices.

For all your wholesale PVC hose needs, look no further than Kingdaflex. We are committed to providing top-quality PVC Steel Wire Reinforced Hoses that meet rigorous industry standards, ensuring you receive durable and high-performing products perfectly suited for your specific requirements here in Qingdao and beyond.

Is PVC Good for Air?

While PVC hoses are used for some air applications like light-duty pneumatic tools or general air transfer at lower pressures, they are generally not recommended for compressed air systems. PVC can become brittle with temperature fluctuations, age, and continuous pressure, posing a significant rupture risk. For high-pressure compressed air, safer alternatives like rubber, polyurethane, or metal piping are preferred.

Is Pvc Toxic to Breathe In?

Breathing in fumes from burning PVC is highly toxic, releasing hazardous chemicals like hydrogen chloride, dioxins, and carbon monoxide, which can cause severe respiratory issues and long-term health problems. While PVC dust from cutting can irritate, the primary concern for toxicity is from combustion.

Can You Use PVC Pipe for Ventilation?

Yes, PVC pipe can be used for ventilation, particularly in HVAC ductwork, passive ventilation, and fume extraction systems for non-combustion gases. Its corrosion resistance, light weight, smooth interior for efficient airflow, and affordability make it a suitable alternative to metal ducting in many applications.

Is It Safe to Drink Water Out of PVC Pipe?

Yes, it is generally safe to drink water from PVC pipes, especially if they are certified for potable water (like NSF/ANSI 61). Modern PVC pipes are designed not to leach harmful chemicals into the water and are widely used in public water distribution systems. However, PVC is not recommended for hot water lines.