In the realm of industrial production, the choice of equipment can make a significant impact on efficiency, reliability, and cost-effectiveness. One piece of equipment that has been gaining prominence in recent years is the peristaltic pump hose.

This innovative technology has proven to be a game-changer in various industrial applications.

In this article, we will delve into the world of peristaltic pump hose and explore why they excel in industrial production.

What Is Peristaltic Pump Hose

A peristaltic pump hose, also known simply as a tube pump, is a specialized type of pump used in various industries for fluid transfer.

What sets it apart from conventional pumps is its unique method of operation, which is inspired by the natural peristaltic motion found in biological systems like the human digestive tract.

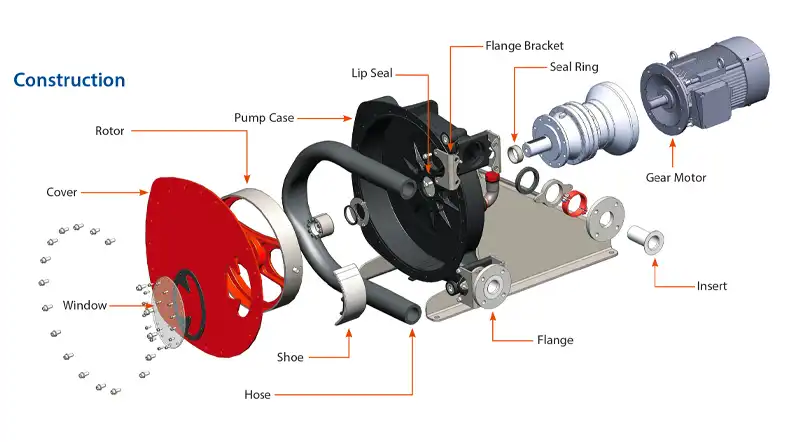

Peristaltic Pump Hose Structure

Let’s delve into the structure of a peristaltic pump hose.

A peristaltic pump hose is a crucial component of peristaltic pumps, which are used in various industries for fluid transfer applications. Understanding the structure of the hose is essential to comprehend how these pumps operate effectively.

1. Outer Layer:

The outer layer of a peristaltic pump hose is the first line of defense against external factors. It is typically made of durable materials like rubber or thermoplastic elastomers. This layer provides protection against physical damage, abrasion, and environmental factors such as UV radiation and chemicals.

2. Reinforcement Layer:

Beneath the outer layer, you’ll find the reinforcement layer. This layer is crucial for maintaining the hose’s structural integrity, especially when it undergoes repeated compression and expansion during pumping. Reinforcement can take the form of high-strength fibers or braids, such as aramid or polyester, embedded within the hose material.

3. Inner Tube:

The inner tube of a peristaltic pump hose is where the fluid flows. It is designed to be highly flexible and resistant to the specific fluid being pumped. Depending on the application, the inner tube can be made from various materials, including natural rubber, silicone, thermoplastic elastomers, or specialty materials compatible with corrosive or abrasive fluids.

4. Compression Zone:

This is the heart of the peristaltic pump hose. It’s the area where the hose is subjected to mechanical compression by the rotating rotor with rollers. As the rotor turns, the rollers gently squeeze the hose, creating a vacuum and drawing the fluid through the tube. This compression zone is what sets peristaltic pumps apart from traditional pumps.

5. Rotor and Rollers:

The rotor is a key component of the peristaltic pump, responsible for driving the hose’s compression. It usually has rollers or shoes attached to it. As the rotor rotates, these rollers compress the hose sequentially, propelling the fluid within the tube.

6. Bearings and Seals:

Bearings and seals are essential for the smooth operation of the rotor. They ensure that the rotor rotates efficiently and prevent any leakage or contamination of the fluid being pumped.

7. End Connections:

At each end of the peristaltic pump hose, there are end connections that allow for easy attachment to the pump and the application. These connections are designed to provide a secure and leak-free fit.

Understanding the structure of a peristaltic pump hose is crucial for maintaining and replacing components when necessary. It’s also essential for selecting the right hose material and configuration based on the specific requirements of an industrial application. Peristaltic pumps and their hoses have gained popularity in various industries due to their efficiency, reliability, and versatility in handling a wide range of fluids while maintaining hygienic and contamination-free processes.

Why Peristaltic (Hose) Pumps Excel In Production

Peristaltic hose pumps, often simply referred to as peristaltic pumps, have emerged as a preferred choice in production processes across various industries.

Their unique design and operational advantages make them excel in the production environment. We’ll explore the key reasons why peristaltic hose pumps are the go-to solution for many production applications.

1. Precise Fluid Handling:

One of the standout features of peristaltic hose pumps is their exceptional precision in fluid handling. These pumps are renowned for their ability to deliver accurate and consistent flow rates, making them indispensable in industries where precise dosing or metering is critical. Whether it’s pharmaceuticals, food production, or chemical processing, peristaltic hose pumps ensure that every drop of fluid is precisely controlled.

2. Versatility in Handling Viscous Fluids:

Production processes often involve fluids with varying viscosities. Peristaltic hose pumps shine in this aspect as well. They are designed to handle a wide range of viscosities, from thin liquids to highly viscous substances. This versatility means that a single peristaltic pump can be used for multiple tasks, reducing the need for different pump types and streamlining production processes.

3. Minimal Maintenance Requirements:

Production downtime can be a significant cost factor, and peristaltic hose pumps are engineered to minimize it. These pumps have a relatively low-maintenance profile, requiring little more than routine tube replacement. Tube replacement is a straightforward task that can be performed quickly, reducing the time and effort spent on maintenance compared to more complex pump types.

4. Contamination-Free Operation:

In industries where hygiene is paramount, such as pharmaceuticals and food production, peristaltic hose pumps have a crucial advantage. The fluid being pumped only comes into contact with the inside surface of the tube. There are no seals or valves that could potentially leak or introduce contaminants. This contamination-free operation ensures product integrity and compliance with stringent quality standards.

5. Durability and Longevity:

Industrial production environments can be harsh, but peristaltic hose pumps are built to withstand them. These pumps are known for their durability and long service life. Their robust construction can handle abrasive or corrosive fluids and the demands of continuous production processes, providing reliable operation over extended periods.

6. Energy Efficiency:

Efficiency is a critical consideration in production. Peristaltic hose pumps are energy-efficient, consuming less power compared to some other pumping solutions. This not only reduces operational costs but also contributes to a greener, more sustainable production process.

7. User-Friendly Design:

Peristaltic hose pumps are designed with user-friendliness in mind. They are easy to operate and require minimal training for personnel. The straightforward tube replacement process and intuitive controls make them accessible to production teams with varying levels of expertise.

Peristaltic hose pumps have carved a niche for themselves in production environments due to their precision, versatility, low maintenance requirements, contamination-free operation, durability, energy efficiency, and user-friendly design. These pumps offer a reliable and cost-effective solution for industries where efficiency, product quality, and compliance with stringent standards are paramount.

Peristaltic Pump Hose Applications

Peristaltic pump hoses are versatile components used in various industrial applications due to their unique design and capabilities. These hoses are characterized by their flexible, cylindrical shape and the way they operate, making them suitable for a wide range of applications. Here are some key applications where peristaltic pump hoses are commonly used:

- Concrete Pumping: Peristaltic pump hoses are extensively used in the construction industry for pumping concrete. Their ability to handle abrasive and viscous materials with high precision makes them ideal for delivering concrete to construction sites, even in challenging or remote locations.

- Chemical Transfer: These hoses are often employed in chemical processing industries for the safe and efficient transfer of corrosive and abrasive fluids. Their design minimizes the risk of contamination and leakage.

- Pharmaceuticals and Biotechnology: Peristaltic pump hoses are utilized in pharmaceutical and biotech industries for precise and sterile fluid handling. They are suitable for transferring sensitive and high-value liquids where contamination must be avoided.

- Food and Beverage: In the food and beverage industry, these hoses are used for pumping and transferring liquids such as sauces, dairy products, and beverages. They are chosen for their hygienic qualities and the ability to handle shear-sensitive fluids without compromising product integrity.

- Water and Wastewater Treatment: Peristaltic pumps are used to dose chemicals, such as disinfectants and coagulants, in water and wastewater treatment processes. Their accurate and reliable dosing capabilities are essential for maintaining water quality.

- Mining and Slurry Transport: Peristaltic pump hoses can handle abrasive and dense slurries commonly found in mining operations. They are valued for their durability and resistance to wear in these harsh environments.

- Oil and Gas: These hoses find applications in the oil and gas industry for various tasks, including transferring drilling mud, chemicals, and crude oil. Their ability to handle abrasive substances is particularly beneficial in these settings.

- Environmental Monitoring: Peristaltic pumps and hoses are used in environmental monitoring and sampling equipment for precise collection and analysis of water samples, ensuring accurate data in environmental studies.

- Laboratory and Scientific Research: In laboratories and research facilities, peristaltic pumps and hoses are used for precise and repeatable fluid dispensing, making them essential for experiments and analytical procedures.

- Agriculture: Peristaltic pumps can be used for applications like fertilization and pesticide spraying in agriculture, where accurate and controlled delivery of fluids is essential.

In summary, peristaltic pump hoses are valued for their reliability, precision, and versatility across a wide range of industries. Their ability to handle various types of fluids, including abrasive, viscous, and shear-sensitive materials, makes them indispensable in many critical applications.

As production processes continue to evolve, peristaltic hose pumps are likely to remain at the forefront of innovation, helping industries excel in their production endeavors.

The operators in some of the world’s most demanding industries – from oil-and-gas production to mining and water/wastewater management to chemical processing – have come to rely on peristaltic pump hose technology when handling thin to viscous, particle-laden, aggressive, abrasive and corrosive liquids in potentially explosive atmospheres is required. In other words, peristaltic pump hose can successfully pump just about anything.

The design and operation of peristaltic pump hose technology, which was patented in 1925 in France, satisfy the requirements of such a wide range of industrial liquid-handling applications because the pump’s operation relies on the alternating contraction and relaxation of the hose, which force the contents to move through the pump and into the discharge hose.

A smooth-wall, flexible hose is fitted in the pump casing and is squeezed between shoes on the rotor that is positioned inside the pump casing. This rotating action moves the product through the hose at a constant rate of displacement. The hose restitution after the squeeze also produces a strong vacuum effect that draws product into the hose from the intake piping. The vacuum that is created by the hose’s restitution can build discharge pressures of as much as 16 bar (232 psi) without damaging or deforming the hose, or causing it to rupture.

This style also maintains excellent volumetric consistency, making it ideal for the strict dosing and 24/7 operating cycles that can be required in many industrial applications while typically providing suction-lift capabilities of as much as 9 meters (29.5 feet). Peristaltic (hose) pumps are also easy to operate and easy to maintain with no seats, valves, glands or mechanical seals needed, which leaves the hose as the pump’s only replacement part.

And for the peristaltic pump hose, if any needs, you can contact us firstly.

Whatsapp: 008618562767380

Email: [email protected]

Skype: kingdaflex