Have you noticed that what is printed on your hydraulic hose? The text printed on the hydraulic hose outer cover is indispensable telling some basically important information about this hydraulic hose.

This is the ultimate guide to the hydraulic hose layline, and today let’s decode the hydraulic hose layline.

Let’s get started.

What Is Hydraulic Hose Layline?

It is easy for you to notice the text printed on the hydraulic hose made by Kingdaflex hydraulic hose manufacturer, and we can customize the layline to print your hydraulic hose brand name, logo and etc.

So why is there a hydraulic hose line? The hydraulic hose layline can tell you something basically important about the hydraulic hose identification.

The hydraulic hose layline can run the whole length of the hydraulic hose, and the information printed on the layline includes hydraulic hose manufacturer, hydraulic hose specifications, such as hydraulic hose size, working pressure, rating and etc.

You can be clear about the hydraulic hose basic info, reading from the hydraulic hose layline, to know how to select the right hydraulic hose for your hydraulic hose application.

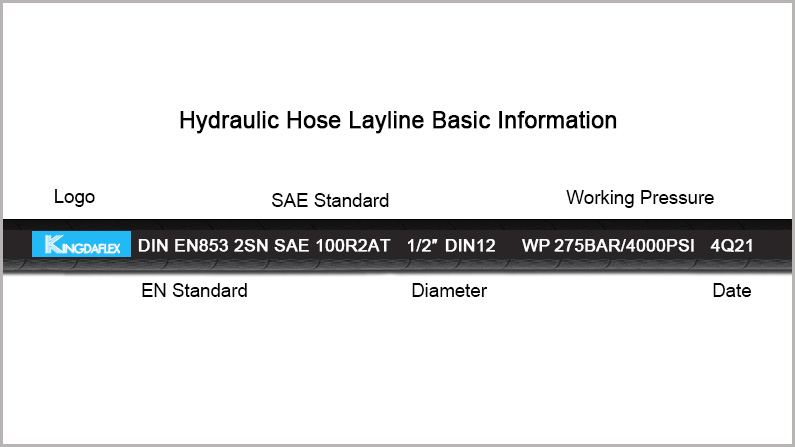

Hydraulic Hose Layline Decode

So let’s decode the hydraulic hose layline:

- Logo: We regularly print our hydraulic hose brand name at the very beginning to show the hydraulic hose manufacturer name, and here we can do the customization, to print your hydraulic hose brand or logo in this place.

- Hydraulic Hose Standard: Here we will print hydraulic hose standards, including hydraulic hose EN standard and SAE standard. The standard information is the must-have information printed on the hydraulic hose layline, to prove that this hydraulic hose is certificated and qualified.

- Diameter: The diameter can tell you the hydraulic hose size, and this is the guide for you to select the right hydraulic hose for your hydraulic system. For example, 1/2″ also 1/2″ inch, is the hydraulic hose dash size, DN12 is the hydraulic hose Nominal Diameter.

- Working Pressure: WP is the abbreviation of Working Pressure. You need to know the working pressure of the hydraulic hose, and then determine where the hydraulic hose can be used for.

- Date: The date can tell you the production date of the hydraulic hose, this is helpful for you to know about the hydraulic hose service life, and guide you to make the hydraulic hose maintenance route. For example, 4Q21 means the 4th quarter in 2021, and this is our latest hydraulic hose published in the market.

For more numbers printed on the hose layline, please get to know what numbers mean on the hydraulic hose.

How to Read Hydraulic Hose Layline

Hydraulic hoses are often marked with various symbols and codes to provide essential information about their specifications and capabilities. Understanding these markings is crucial for selecting the correct hose for your application and ensuring safe and efficient operation.

Here’s a breakdown of common hydraulic hose markings:

1. Society of Automotive Engineers (SAE) J1401:

- Three-letter code: This code indicates the hose’s construction and suitability for different applications.

- Example: SAE 100R2 – A reinforced hose suitable for general hydraulic applications.

2. Tube and Fittings Association (TFA):

- Four-letter code: This code provides information about the hose’s construction, maximum working pressure, and temperature range.

- Example: TFA 1200 – A high-pressure hose with a maximum working pressure of 1200 psi.

3. British Standards Institution (BSI):

- Two-letter code: This code indicates the hose’s construction and suitability for different applications.

- Example: BS EN 853 – A general-purpose hydraulic hose.

4. Other Standards:

- ISO, DIN, and JIS: These international standards also have their own coding systems for hydraulic hoses.

5. Layline Markings:

- Arrows or symbols: These markings indicate the direction of fluid flow within the hose.

- Importance: Correct installation based on layline markings is essential for preventing system damage and ensuring optimal performance.

6. Date Codes:

- Numbers or letters: These codes indicate the date of manufacture.

- Importance: Understanding the hose’s age can help determine its remaining service life and when it should be replaced.

Additional Tips:

- Consult the hose manufacturer‘s documentation: For specific information about a particular hose, refer to the manufacturer‘s technical data sheets or catalogs.

- Use a hydraulic hose reference guide: Many online and printed resources provide comprehensive information on hydraulic hose markings and specifications.

- Seek professional advice: If you’re unsure about reading hydraulic hose markings or selecting the right hose for your application, consult with a hydraulics expert or a qualified supplier.

By understanding these markings, you can make informed decisions about hydraulic hose selection, installation, and maintenance, ensuring the reliability and safety of your hydraulic systems.

What Is the Hydraulic Hose Layline Purpose?

The hydraulic hose layline can be the important marking label, the hydraulic hose labels can help you a lot to indicate the hydraulic hose basics to the buyers. The clients will know hydraulic hose basic information, including hydraulic hose size, pressure and etc.

How to read a hydraulic hose? The hydraulic hose layline matters the most important, they can be seen as the hydraulic hose identification labels, telling you everything important the hydraulic hose specifications printed on the hydraulic hose layline existing on the surface of the hydraulic hose cover.

Reading hydraulic hose layline is also important, which can help you with the hydraulic hose selection. The STAMPED principle works well for you to choose the most suitable hydraulic hose for your hydraulic machine, and also you can get the information useful for your hydraulic system.

It’s flexible for you to customize the hydraulic hose layline, and we can print anything you want, such as your wanted color, art, surface and etc. The hose layline can be used as the visual index for hydraulic hose routing for installation tips.

The hydraulic hose layline is the identification label of a hydraulic hose, and you need to be clear about the meaning of the layline numbers before you use them.

Hydraulic Hose Layline Printing Methods

Hydraulic hose layline printing is a process used to mark the direction of flow within a hydraulic hose. This helps prevent incorrect installation, which can lead to system failure or damage. There are several methods used for layline printing:

1. Ink-Based Printing:

- Offset printing: This method is commonly used for large-scale production. The ink is transferred from a plate to a rubber blanket and then to the hose.

- Flexographic printing: This method uses a flexible printing plate that is wrapped around a cylinder. It is suitable for both large and small-scale production.

- Screen printing: This method uses a stencil with a mesh screen. Ink is forced through the mesh onto the hose. It is often used for custom printing.

2. Laser Engraving:

- Laser marking: A laser beam is used to create a permanent mark on the hose. This method is highly precise and can produce fine details.

- Laser ablation: A laser beam is used to remove material from the hose surface, creating a visible mark. This method is suitable for marking on dark-colored hoses.

3. Hot Stamping:

- Foil stamping: A metal foil is heated and pressed onto the hose, leaving a permanent mark. This method is often used for decorative or high-quality markings.

4. Chemical Etching:

- Acid etching: A chemical solution is used to etch a mark onto the hose surface. This method is suitable for marking on metal hoses.

5. Pad Printing:

- Pad printing: A pad is used to transfer ink from a plate to the hose. This method is suitable for printing on curved surfaces and irregular shapes.

6. Digital Printing:

- Inkjet printing: Ink is sprayed onto the hose using inkjet technology. This method allows for high-resolution and variable data printing.

The choice of method depends on factors such as the volume of production, the desired level of detail, the type of hose, and the cost.

Final Thoughts

Hydraulic hose layline is a crucial component of any hydraulic system, ensuring correct fluid flow and preventing equipment damage. Understanding and accurately interpreting layline markings is essential for technicians and operators to maintain optimal system performance.

Key takeaways from this guide:

- Layline purpose: The layline indicates the direction of fluid flow within the hose.

- Decoding methods: Various techniques, including color coding, arrows, and symbols, are used to identify layline directions.

- Importance of correct installation: Improper hose installation can lead to system malfunctions, reduced efficiency, and costly repairs.

- Customized solutions: For specific applications or branding needs, custom hydraulic hose layline printing can be tailored to meet individual requirements.

Want to add a unique touch to your hydraulic system while ensuring optimal performance? Consider customizing your hydraulic hose with your own logo or branding.

By incorporating your company’s logo or a specific identifier, you can:

- Enhance brand visibility: Make a statement and reinforce your corporate identity.

- Improve traceability: Easily identify and track your equipment.

- Reduce the risk of errors: Minimize the chance of incorrect hose installation.

Contact us today to discuss your customization options and explore how we can help you create a hydraulic hose that perfectly aligns with your needs.