Thermoplastic polyurethane (TPU) is a versatile and high-performance polymer material that has gained widespread use in numerous industries. Unlike traditional thermoset polyurethanes, TPU is a thermoplastic material, meaning it can be heated, molded, and reshaped repeatedly without losing its essential properties.

The unique molecular structure of TPU, which combines the characteristics of both plastic and rubber, gives it a unique set of attributes that make it an attractive choice for various applications, particularly in the realm of industrial hoses.

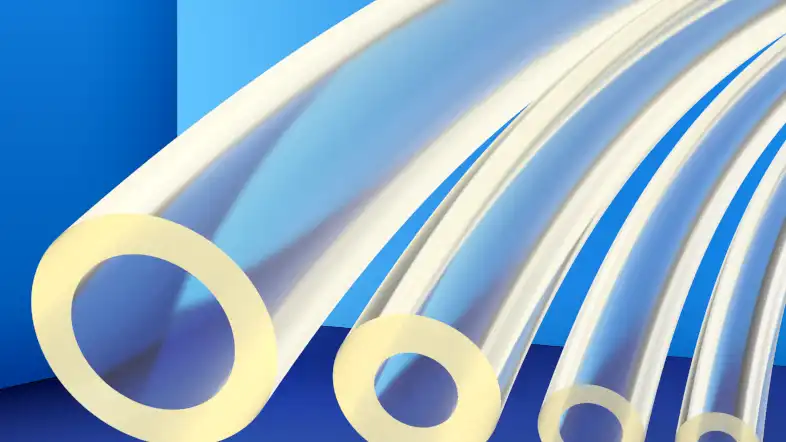

What Is a TPU Hose

A TPU hose is a type of industrial hose that is manufactured using thermoplastic polyurethane as the primary material. These hoses are designed to provide a balance of flexibility, durability, and chemical resistance, making them suitable for a wide range of applications.

Unlike traditional rubber or PVC hoses, TPU hoses offer several distinct advantages that have made them a preferred choice in numerous industries. Let’s explore the key features and benefits of TPU hoses in more detail.

What Is TPU Material

Thermoplastic Polyurethane (TPU) is a versatile and high-performance polymer material that has gained significant attention in various industries.

Here’s a detailed overview of TPU material:

Composition and Structure:

- TPU is a type of thermoplastic elastomer that combines the characteristics of both plastic and rubber.

- It is composed of two main components: a hard segment (typically a diisocyanate) and a soft segment (typically a polyol).

- The unique molecular structure of TPU, with its hard and soft segments, gives it the ability to be heated, molded, and reshaped repeatedly without losing its essential properties.

Key Properties of TPU:

- Flexibility and Elasticity: TPU exhibits excellent flexibility and elasticity, allowing it to bend and stretch without losing its shape or structural integrity.

- Durability and Abrasion Resistance: TPU is known for its exceptional durability and resistance to abrasion, making it well-suited for applications that require high levels of wear and tear resistance.

- Chemical Resistance: TPU demonstrates excellent resistance to a wide range of chemicals, solvents, oils, and other aggressive substances, making it suitable for use in various industrial environments.

- Temperature Resistance: TPU can operate across a broad temperature range, typically from -40°C (-40°F) to 90°C (194°F), making it versatile for use in diverse climates and applications.

- Lightweight: Compared to traditional rubber or metal materials, TPU is generally lightweight, contributing to easier handling and reduced system weight.

- Electrical Conductivity: Depending on the specific formulation, TPU can be designed with conductive or anti-static properties, which is crucial for applications where static electricity dissipation is important.

- FDA and Food-Grade Compliance: TPU can be manufactured to meet FDA and other food-grade regulations, making it suitable for use in the food, beverage, and pharmaceutical industries.

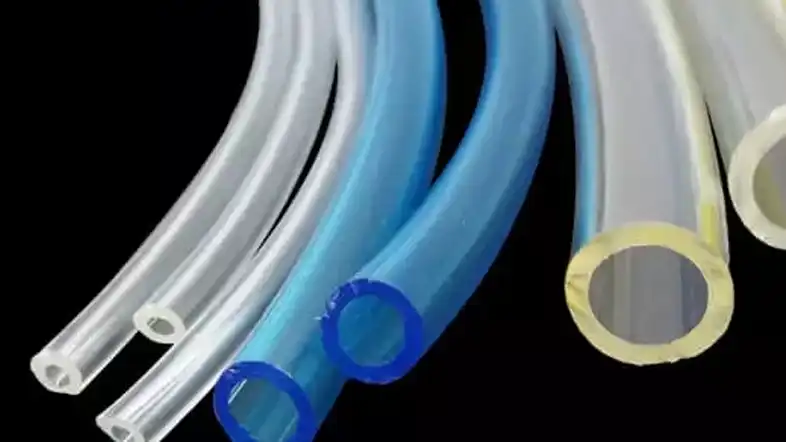

TPU Hose Types

Here are the main types of TPU (Thermoplastic Polyurethane) hoses and their key characteristics:

Reinforced TPU Hoses:

- Constructed with an inner TPU lining and a reinforced outer layer, typically made of braided fabric or wire.

- Provide enhanced pressure and burst resistance, making them suitable for high-pressure applications.

- Offer improved kink resistance and dimensional stability compared to non-reinforced TPU hoses.

- Commonly used in hydraulic systems, pneumatic equipment, and other industrial applications requiring high-pressure tolerance.

Non-Reinforced TPU Hoses:

- Consist of a single layer of TPU material without any additional reinforcement.

- Offer excellent flexibility, conformability, and ease of installation, making them suitable for applications with lower pressure requirements.

- Commonly used in applications such as material handling, food and beverage transfer, and low-pressure pneumatic systems.

Conductive/Anti-Static TPU Hoses:

- Designed with the ability to dissipate static electricity and prevent the buildup of static charges.

- Incorporate conductive fillers or additives within the TPU material to provide static-dissipative properties.

- Useful in applications where the risk of static electricity discharge is a concern, such as in the chemical, petrochemical, and electronics industries.

FDA/Food-Grade TPU Hoses:

- Manufactured to meet FDA (Food and Drug Administration) and other food-grade regulations and standards.

- Formulated with TPU materials that are safe for contact with food, beverages, and pharmaceutical products.

- Commonly used in the food and beverage processing, pharmaceutical, and biotechnology industries.

TPU Layflat Hoses:

Designed to collapse and lay flat when not in use, reducing storage space requirements.

Constructed with a TPU inner lining and a reinforced outer layer, often with a woven fabric or mesh.

Offer flexibility and conformability, allowing the hose to easily navigate around obstacles and through tight spaces.

Commonly used in applications where portability, space-saving, and ease of handling are important, such as:

- Irrigation and agricultural water transfer

- Temporary water supply lines

- Emergency response and disaster relief operations

- Construction site dewatering

The layflat design enables the hose to be easily transported, deployed, and stored when not in use, enhancing overall efficiency and convenience.

Specialty TPU Hoses:

Designed for specific applications or environments, such as:

- UV-resistant TPU hoses for outdoor use in agricultural or construction applications.

- Low-temperature TPU hoses for use in cold environments.

- Hoses with enhanced chemical resistance for exposure to aggressive substances.

These specialized TPU hoses are tailored to meet the unique requirements of the application.

When selecting the appropriate TPU hose type, it is crucial to consider factors such as pressure, temperature, chemical exposure, regulatory compliance, and the specific demands of your application. Consulting with a knowledgeable TPU hose manufacturer or supplier can help you identify the optimal hose solution for your needs.

Key Features of TPU Hoses

- Flexibility and Kink Resistance: One of the standout features of TPU hoses is their exceptional flexibility. The thermoplastic nature of the material allows these hoses to bend and flex with ease, enabling them to navigate tight spaces and complex routing without kinking or collapsing. This flexibility enhances their versatility and ease of installation.

- Durability and Abrasion Resistance: TPU hoses are renowned for their durability and resistance to abrasion. The material’s inherent toughness and abrasion-resistant properties make these hoses well-suited for harsh industrial environments, where they can withstand the wear and tear of repeated use, contact with rough surfaces, and exposure to various external factors.

- Chemical Resistance: Thermoplastic polyurethane is known for its excellent chemical resistance, allowing TPU hoses to withstand exposure to a wide range of chemicals, solvents, oils, and other aggressive substances. This makes them suitable for applications where the hose may come into contact with various fluids or chemicals.

- Temperature Resistance: TPU hoses are capable of operating across a broad temperature range, typically from -40°C (-40°F) to 90°C (194°F). This temperature resistance allows them to function reliably in both hot and cold environments, making them versatile for use in diverse industrial settings.

- Lightweight Construction: Compared to traditional rubber or metal hoses, TPU hoses are generally lightweight, contributing to easier handling, reduced installation challenges, and lower overall system weight. This attribute is particularly beneficial in applications where portability and maneuverability are essential.

- Electrical Conductivity: Depending on the specific formulation, some TPU hoses can be designed with conductive or anti-static properties. These specialized hoses are used in applications where the dissipation of static electricity is critical, such as in the handling of flammable liquids or powders.

- FDA and Food-Grade Compliance: For the food, beverage, and pharmaceutical industries, TPU hoses can be manufactured to comply with FDA and other food-grade regulations. These hoses are designed to meet stringent requirements for purity, cleanliness, and suitability for contact with food and medical-grade products.

Benefits of Using TPU Hoses

The unique features of TPU hoses translate into a range of benefits that make them an attractive choice for various industrial applications. Let’s explore some of the key advantages of using TPU hoses:

- Increased Operational Efficiency: The flexibility and kink resistance of TPU hoses allow for easier installation, routing, and maneuvering, reducing the time and effort required for hose deployment. This, in turn, can enhance overall.

- Improved Durability and Longevity: The exceptional durability and abrasion resistance of TPU hoses contribute to their extended service life, reducing the frequency of replacements and maintenance requirements. This can lead to lower long-term operational costs and increased productivity.

- Enhanced Safety: The chemical resistance and temperature tolerance of TPU hoses help mitigate the risks associated with exposure to various fluids, chemicals, and extreme temperatures. This enhanced safety profile is particularly important in industrial settings where worker safety is a top priority.

- Versatility and Adaptability: The versatile nature of TPU hoses allows them to be used in a wide range of applications, from fluid transfer and pneumatic systems to specialized industrial processes. This adaptability enables businesses to streamline their inventory and reduce the need for multiple hose types.

- Compliance and Regulatory Adherence: For industries with strict regulations, such as food, beverage, and pharmaceutical, TPU hoses that are FDA-approved and food-grade compliant can help businesses meet stringent industry standards and ensure the safety and purity of their products.

- Environmentally Friendly: Compared to traditional rubber or PVC hoses, TPU hoses can be more environmentally friendly due to their recyclability and reduced environmental impact during the manufacturing process. This aligns with the growing emphasis on sustainable practices in various industries.

Applications of TPU Hoses

Here are the key applications of TPU (Thermoplastic Polyurethane) hoses:

Automotive and Transportation:

- Fuel lines

- Brake systems

- Air conditioning systems

- Other vehicle fluid transfer applications

Industrial Manufacturing:

- Pneumatic systems

- Hydraulic equipment

- Material handling applications

- General industrial fluid transfer

Food and Beverage Processing:

- Transfer of liquids, syrups, and other food-grade products

- Meet FDA and food-grade compliance requirements

Pharmaceutical and Biotechnology:

- Handling and transfer of sensitive pharmaceutical ingredients

- Medical-grade fluid transfer

- Comply with stringent purity and cleanliness standards

Mining and Construction:

- Pneumatic tools

- Hydraulic systems

- Material handling applications

Chemical and Petrochemical:

- Transfer of solvents, acids, and other aggressive chemicals

- Excellent chemical resistance

Agriculture and Irrigation:

- Flexible and durable hoses for fertilizer and chemical applications

- UV resistance for outdoor use

TPU Hose Selection

When selecting the right TPU (Thermoplastic Polyurethane) hose for your application, there are several key factors to consider to ensure optimal performance and longevity. Here are the main considerations for TPU hose selection:

Application Requirements:

- Pressure: Determine the maximum operating pressure the hose will be subjected to and select a hose with an appropriate pressure rating.

- Temperature: Understand the temperature range the hose will be exposed to, both in terms of the fluid/material being transferred and the ambient conditions.

- Chemical Exposure: Identify the specific chemicals, solvents, or other aggressive substances the hose will come into contact with and ensure the TPU formulation can withstand them.

- Environmental Conditions: Consider factors such as UV exposure, abrasion, or other environmental stresses the hose may face in its intended application.

TPU Hose Specifications:

- Diameter: Choose the appropriate hose diameter based on the flow rate, pipe/fitting sizes, and space constraints of your system.

- Length: Determine the required hose length to accommodate your application’s layout and connectivity needs.

- Wall Thickness: Select a hose with the appropriate wall thickness to balance flexibility, pressure rating, and durability requirements.

- Fittings and Connections: Ensure the hose is compatible with the necessary fittings, couplings, and connections used in your system.

Regulatory Compliance:

- If your application requires compliance with specific industry standards or regulations, such as FDA approval for food-grade applications or ISO certifications, ensure the TPU hose you choose meets those requirements.

- Look for hoses that are explicitly certified or approved for the relevant industry standards and regulations.

Customization Options:

- Many TPU hose manufacturers offer customization options, such as custom lengths, specialized fittings, or unique color coding.

- Explore these customization possibilities to find a hose that is tailored to your specific application needs.

Manufacturer Reputation and Reliability:

- Research the reputation and track record of the TPU hose manufacturer to ensure you are working with a reliable and reputable supplier.

- Look for certifications, customer testimonials, and industry recognition to gauge the quality and reliability of their products.

Total Cost of Ownership:

- Consider not only the initial purchase price of the TPU hose but also the long-term operational costs, such as maintenance, replacement intervals, and potential downtime.

- Evaluate the total cost of ownership to ensure you are selecting a hose that provides the best value and long-term performance.

By carefully considering these factors, you can select the most appropriate TPU hose for your application, ensuring optimal performance, reliability, and cost-effectiveness.

Maintaining and Caring for TPU Hoses

To ensure the long-term performance and reliability of your TPU hoses, proper maintenance and care are essential. Here are some best practices for maintaining TPU hoses:

- Regular Inspections: Conduct periodic visual inspections of your TPU hoses to check for any signs of wear, damage, or deterioration, such as cracks, abrasions, or leaks. Address any issues promptly to prevent further damage and ensure the continued safe operation of the hose.

- Proper Storage and Handling: When not in use, store TPU hoses in a cool, dry place, away from direct sunlight and heat sources. Avoid kinking or bending the hoses during storage, as this can compromise their flexibility and durability.

- Cleaning and Flushing: Regularly clean and flush the TPU hoses to remove any accumulated debris, residues, or contaminants that may have built up during use. This helps maintain the hose’s flow efficiency and prevent potential issues.

- Replacement Recommendations: Follow the manufacturer‘s guidelines for the recommended service life and replacement intervals of your TPU hoses. Replacing hoses before they reach the end of their useful life can help avoid unexpected failures and ensure continued reliable performance.

Conclusion: Embracing the Power of TPU Hoses

Thermoplastic polyurethane (TPU) hoses have emerged as a versatile and high-performance solution for a wide range of industrial applications. With their exceptional flexibility, durability, chemical resistance, and temperature tolerance, TPU hoses offer a compelling alternative to traditional rubber or PVC hoses.

Interested in Unlocking the Power of TPU Hoses?

If you’re looking to enhance the efficiency, reliability, and safety of your operations, we invite you to explore the transformative potential of Thermoplastic Polyurethane (TPU) hoses.

Our team of experts is dedicated to helping you find the perfect TPU hose solution tailored to your unique application requirements. Whether you’re in the automotive, manufacturing, food and beverage, or any other industry, we have the expertise and product portfolio to deliver a customized TPU hose that will take your operations to new heights.

Don’t hesitate to reach out to us at any time. Our knowledgeable representatives are standing by to provide personalized guidance, answer your questions, and help you navigate the world of TPU hoses.

Contact us today at Kingdaflex and let’s embark on a journey to unlock the full potential of TPU technology for your business.

We look forward to hearing from you and helping you achieve your goals.