We offer concrete pump hoses designed for robust and reliable concrete transfer. Our hoses are engineered to withstand high pressures and abrasive concrete mixtures, ensuring durability and longevity. Available in various sizes and lengths, our concrete pump hoses provide optimal performance and efficiency for your construction projects. Trust Kingdaflex for superior concrete pumping solutions.

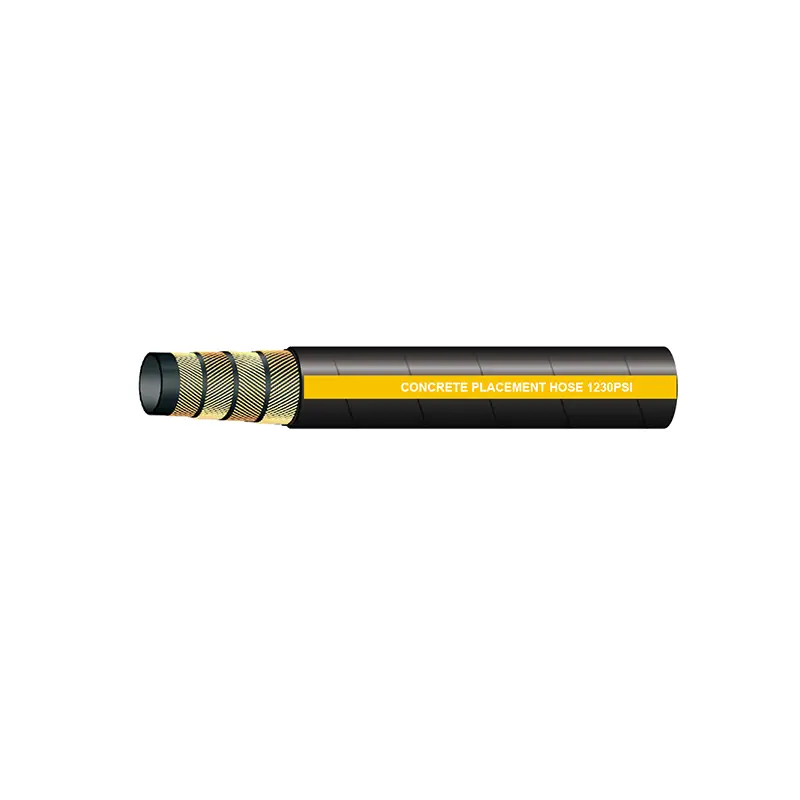

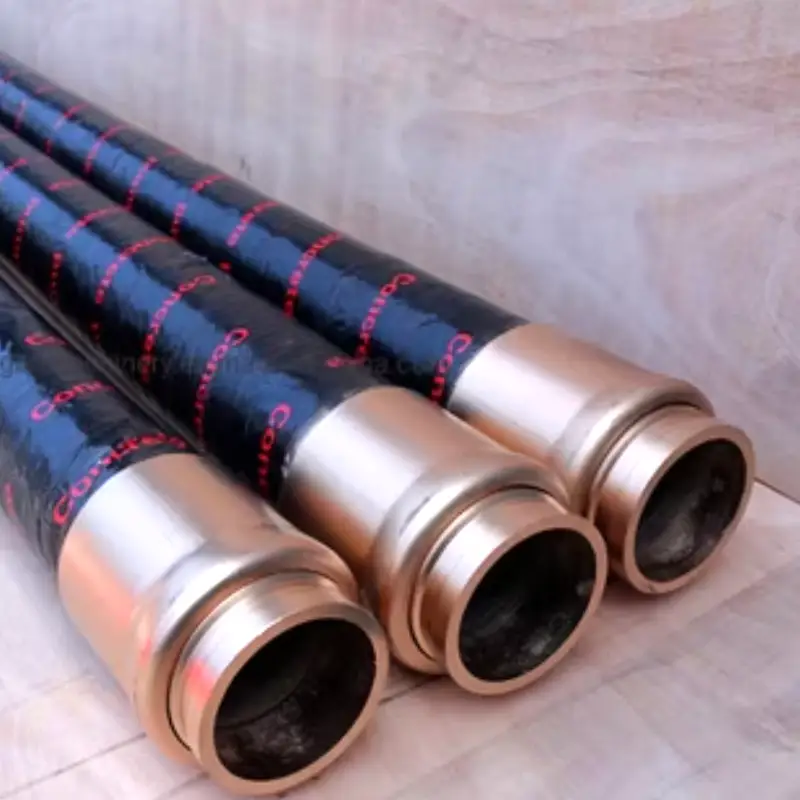

Inner Tube: This is the innermost layer that comes into direct contact with the flowing concrete. It’s made from a highly abrasion-resistant synthetic rubber compound, often a blend of natural rubber (NR) and Styrene Butadiene Rubber (SBR). Its primary role is to resist the constant wear from the aggregate in the concrete mixture.

Reinforcement Layers: This is the core structural component responsible for the hose’s strength. It consists of multiple layers of high-tensile materials, typically braided or spiraled steel wire or polyester cord. These plies enable the hose to withstand the high internal pressure of the concrete pumping process and prevent it from bursting.

Outer Cover: The outermost layer is a durable rubber compound, also commonly a blend of SBR/NR. Its purpose is to protect the inner layers from external damage, including abrasion, cuts, weather, and ozone exposure. This cover ensures the hose remains intact and functional even in harsh outdoor conditions.

Precise Concrete Placement The final hose section allows workers to accurately guide the concrete mixture into formwork, molds, or small pouring areas, providing crucial flexibility and control at the point of delivery.

Pumping to Elevated Structures Attached to boom pumps, the robust hose extends the reach vertically, making it indispensable for transferring concrete efficiently to the upper floors of high-rise buildings and elevated bridge decks.

Horizontal Concrete Conveyance Used with line pumps, multiple hoses are laid across the ground to move concrete over long distances, often through tight or congested sites where truck access is completely restricted.

Navigating Obstacles on Site The hose’s inherent flexibility allows the pumping line to be maneuvered around existing utilities, landscaping, and foundation elements, ensuring concrete can reach otherwise inaccessible sections of a project.

Applying Shotcrete and Grout Specialized concrete hoses are also utilized for high-pressure spraying of repair materials like shotcrete (sprayed concrete) and transporting abrasive, thick grouting mixtures for tunneling and mining applications.

Delight your clients with our premium wholesale concrete pump hoses, engineered for exceptional durability and performance. Kingdaflex offers a wide range of sizes and specifications, ensuring you meet diverse project demands. Our hoses withstand high pressures and abrasive materials, reducing downtime and enhancing efficiency. Provide your clients with reliable, long-lasting solutions, boosting their operational success. Request a quote today.

We adjust hose length to ensure precise concrete placement, minimizing waste and maximizing efficiency. Longer hoses reach distant locations, while shorter hoses offer maneuverability in confined spaces. We tailor length to reduce the need for multiple hose sections and minimize connection points, reducing potential leak risks.

We choose the right hose material to ensure durability and longevity in harsh construction environments. Abrasion-resistant rubber or synthetic composites withstand the abrasive nature of concrete. Reinforced materials handle high pressures, preventing bursts and leaks. We customize material to extend hose lifespan and reduce maintenance costs.

We select the appropriate hose diameter to optimize concrete flow and pump performance. Larger diameters handle high-volume pumping, while smaller diameters are suitable for precise placement. We match diameter to concrete consistency and pump capacity to prevent blockages and ensure consistent flow rates, enhancing project efficiency.

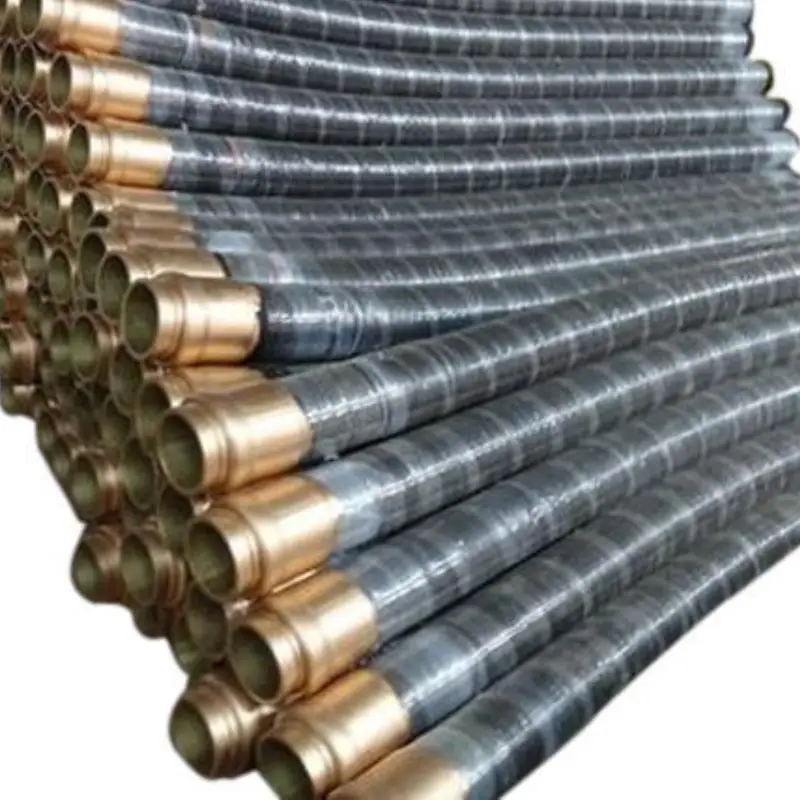

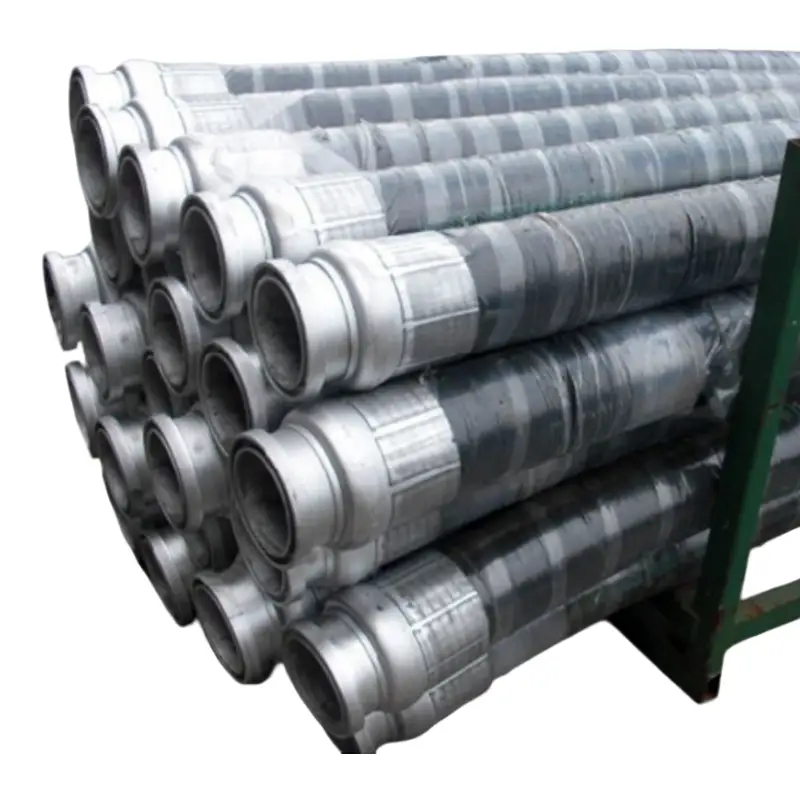

We customize fittings and couplings to ensure secure and leak-free connections to pumping equipment and placement tools. Selecting compatible sizes and types prevents pressure loss and ensures smooth concrete flow. We offer quick-connect couplings to facilitate rapid hose changes, minimizing downtime and enhancing operational efficiency.

Kingdaflex offers high-performance concrete pumping hoses, engineered for demanding construction projects. Our concrete pump hoses are built to withstand high pressures and abrasive concrete mixtures, ensuring reliable and efficient concrete transfer. Available in various sizes and lengths, our durable hoses minimize downtime and maximize productivity. Trust Kingdaflex for your wholesale concrete pumping hose needs.

Kingdaflex offers high-performance 2-inch concrete pump hoses, designed for efficient and reliable concrete transfer. Our hoses are engineered to withstand high pressures and abrasive materials, ensuring durability and longevity. Ideal for smaller to medium-sized concrete pumping projects, our 2-inch hoses provide optimal flow and flexibility. Trust Kingdaflex for quality and performance.

Kingdaflex offers high-performance 3-inch concrete pump hoses, engineered for efficient and reliable concrete transfer. Our 3-inch hoses are designed to withstand high pressures and abrasive concrete mixtures, ensuring durability and longevity on construction sites. We provide robust solutions tailored to meet your wholesale needs, guaranteeing optimal performance and minimal downtime.

Kingdaflex offers high-performance 4-inch concrete pump hoses, engineered for efficient and robust concrete transfer. These hoses are designed to withstand high pressures and abrasive materials, ensuring durability and longevity. Ideal for large-scale construction projects, our 4-inch hoses provide optimal flow and reliability, minimizing downtime and maximizing productivity.

Kingdaflex offers high-performance concrete line pump hoses designed for efficient and reliable concrete transfer. Our hoses are built to withstand the rigors of line pumping, ensuring smooth operation and minimal downtime. Available in various sizes and pressure ratings, our hoses provide flexibility and durability for diverse construction needs. Trust Kingdaflex for top-quality concrete line pump hoses.

Kingdaflex provides top-grade concrete pump end hoses, designed for precise and efficient concrete placement. Our end hoses offer superior flexibility and durability, ensuring smooth operation and minimizing material waste. Engineered to withstand high pressures and abrasive materials, our hoses deliver reliable performance on any construction site. Trust Kingdaflex for your concrete pumping needs.

Kingdaflex offers high-performance concrete pump rubber hoses, crafted for demanding construction environments. Our hoses are engineered with robust rubber compounds, ensuring exceptional durability and resistance to abrasion. Designed to handle high-pressure concrete transfer, our products guarantee reliability and longevity. We provide various sizes to meet your specific project needs.

Kingdaflex offers high-performance concrete pump truck hoses, engineered for demanding construction environments. Our hoses are built to withstand high pressures and abrasive concrete mixtures, ensuring reliable and efficient concrete transfer. Available in various sizes and lengths, our hoses provide optimal flexibility and durability, minimizing downtime and maximizing productivity for your concrete pumping operations.

Kingdaflex offers high-performance lay flat concrete pump hoses, designed for efficient and flexible concrete transfer. These hoses are engineered for easy deployment and storage, providing exceptional durability and resistance to abrasion. Ideal for various construction applications, our lay flat hoses ensure reliable performance and minimize setup time. Trust Kingdaflex for your concrete pumping needs.

Kingdaflex offers high-performance mud snake concrete pumping hoses, designed for flexible and efficient concrete placement in challenging environments. These hoses are engineered for durability and maneuverability, allowing for precise concrete delivery in hard-to-reach areas. Our mud snake hoses ensure reliable performance and minimize material waste, optimizing your concrete pumping operations.

Kingdaflex offers high-performance concrete pump flexible hoses, designed for exceptional maneuverability and robust concrete transfer. Our hoses maintain flexibility under high pressure, ensuring efficient and precise concrete placement. Built with durable materials, they resist abrasion and wear, providing long-lasting reliability for your construction projects. Choose Kingdaflex for flexible, durable solutions.

Kingdaflex provides high-performance peristaltic concrete pump hoses, designed for precise and consistent concrete transfer. Our hoses are engineered to withstand the demanding pressures and abrasive nature of concrete, ensuring reliable and long-lasting operation. With various sizes and materials, we offer solutions tailored to your specific pumping needs, guaranteeing optimal efficiency and minimal downtime

We provide OEM concrete pump hoses, expertly engineered for demanding construction projects. Our hoses feature multi-ply steel wire or textile reinforcement, ensuring exceptional pressure resistance and durability. They are also highly flexible for easy handling and efficient concrete placement. We offer customizable solutions to meet your specific equipment needs.

Our durable rubber concrete hoses are engineered for high-pressure, abrasive pumping of concrete, grout, and mortar. Featuring steel-wire reinforcement and superior abrasion-resistant rubber, they ensure safe, flexible, and efficient material transfer on all construction sites, minimizing downtime and maximizing productivity.

A concrete pump hose is a specialized, heavy-duty hose designed to transport concrete from a concrete pump to the desired placement location on a construction site. These hoses are engineered to handle the abrasive nature of concrete mixtures, which often include sand, gravel, and cement, and to withstand the high pressures generated by concrete pumps. Their flexibility and durability are crucial for efficiently and accurately delivering concrete to various locations, including high-rise buildings, foundations, and other challenging construction environments.

These hoses are typically constructed from reinforced rubber or synthetic materials, providing the necessary strength and wear resistance. They come in various diameters and lengths to accommodate different pumping capacities and placement requirements. The design prioritizes flexibility to allow for easy maneuverability around obstacles and precise placement of concrete. The hoses are often reinforced with steel wire or fabric plies to ensure they can withstand the rigorous demands of concrete pumping operations, minimizing the risk of bursts or leaks.

Concrete pump hoses are engineered to withstand the abrasive nature of concrete and the high pressures involved in pumping. Their construction involves a combination of materials designed for durability, flexibility, and resistance to wear. The specific materials used can vary depending on the hose’s intended application and pressure rating, but they generally include a reinforced rubber or synthetic inner tube and a robust outer cover.

Here are the primary components and materials used in concrete pump hose construction:

Inner Tube (Liner):

Typically made from highly abrasion-resistant synthetic rubber compounds, such as styrene-butadiene rubber (SBR) or natural rubber blends.

This layer comes into direct contact with the concrete and must withstand the abrasive forces of the mixture.

The inner tube is designed to be smooth to minimize friction and ensure a consistent flow of concrete.

Consist of multiple layers of high-tensile steel wire braiding or textile plies.

These layers provide the hose with the necessary strength to withstand high pressures and prevent bursting.

The number and type of reinforcement layers vary depending on the hose’s pressure rating and application requirements.

Outer Cover (Jacket):

Made from a durable synthetic rubber compound, such as chloroprene rubber (CR) or styrene-butadiene rubber (SBR).

This layer protects the reinforcement layers from abrasion, weathering, and other environmental factors.

The outer cover is designed to be resistant to cuts, tears, and other forms of mechanical damage.

Concrete pump hoses are essential tools in modern construction, facilitating the efficient and precise placement of concrete. Their specialized design allows for versatile applications across various construction projects.

High-Rise Building Construction:

Concrete pump hoses enable the vertical transportation of concrete to upper floors, overcoming the challenges of traditional methods. They ensure a continuous and controlled flow, crucial for maintaining structural integrity and construction timelines in tall buildings.

Bridge and Tunnel Construction:

In bridge and tunnel projects, these hoses facilitate the placement of concrete in hard-to-reach areas. Their flexibility and durability allow for precise pouring, ensuring structural stability and longevity in complex infrastructure projects.

Foundation and Slab Pouring:

Concrete pump hoses are used for pouring foundations and slabs, ensuring even distribution and efficient placement. They streamline the process, reducing labor and time, and guaranteeing a consistent and high-quality concrete finish.

Shotcrete Applications:

For shotcrete applications, these hoses deliver concrete under pressure, allowing for precise application on vertical or overhead surfaces. They are vital for stabilizing slopes, reinforcing structures, and creating intricate architectural designs.

Preventing concrete pump hose whip is critical for job site safety, as it can cause serious injury or death. The whipping action is a result of a sudden, violent release of compressed air that has become trapped behind a blockage in the concrete line.

To avoid this dangerous event, workers must follow a series of safety protocols:

Proper Priming and Mix Consistency: Always prime the pipeline with a suitable lubricating agent (such as a grout) before concrete is introduced. Ensure the concrete mix is pumpable and consistent to prevent blockages.

Controlled Pumping: Start the pump at a slow, gradual pace to minimize the risk of a pressure surge.

Constant Monitoring: The pump operator must continuously monitor the concrete level in the hopper to prevent the pump from sucking in air. A separate person should be designated to watch the hopper if the operator’s view is obstructed.

Safe Blockage Clearance: Never attempt to clear a blockage by applying excessive pressure or by using a hammer or other objects on the hose. Use safe, established procedures to relieve pressure and clear the blockage.

Exclusion Zones: Maintain a strict exclusion zone around the hose, especially during start-up, shut-down, and while clearing blockages. The area should be kept clear of all non-essential personnel.

Maintenance and Inspection: Regularly inspect hoses for any signs of wear, kinks, or damage. Replace any damaged hoses immediately. Additionally, ensure all clamps and couplings are properly secured and pinned before operation.

Installing a concrete pump hose correctly is crucial for ensuring safe and efficient concrete pumping operations. Proper installation prevents leaks, blockages, and potential hose damage, maintaining the integrity of the pumping system. We will guide you through the essential steps for installing a concrete pump hose.

Step 1: Preparation and Inspection

Before installation, thoroughly inspect the concrete pump hose for any signs of damage, such as cuts, abrasions, or cracks. Ensure the hose is clean and free of debris. Verify that the hose’s diameter and pressure rating are compatible with the concrete pump and the intended application. Inspect the fittings and couplings for any damage or wear.

Step 2: Connecting the Hose to the Pump

Carefully align the hose with the pump’s outlet and secure it using the appropriate fittings and clamps. Ensure the connection is tight to prevent leaks under pressure. Use thread sealant or Teflon tape if necessary. Double-check that the hose is properly seated and that the clamps are tightened to the manufacturer’s specifications to avoid slippage or detachment during operation.

Step 3: Routing and Securing the Hose

Route the hose to the desired concrete placement location, avoiding sharp bends or kinks that could restrict flow or damage the hose. Use hose supports or restraints to secure the hose and prevent excessive movement or vibration during pumping. Ensure the hose is positioned to minimize strain on the connections and prevent tripping hazards on the work site.

Step 4: Testing and Operation

After installation, perform a test run with water or a low-pressure concrete mix to check for leaks or blockages. Gradually increase the pressure and flow rate, monitoring the hose and connections for any signs of distress. Ensure the hose is operating smoothly and that the concrete is being delivered to the desired location without any issues.

Maintaining a clean concrete pump hose is crucial for preventing blockages and ensuring efficient concrete pumping operations. Regular cleaning extends the hose’s lifespan and minimizes downtime. We will guide you through the effective steps to clean a concrete pump hose.

Step 1: Initial Water Flush

Begin by flushing the hose with clean water. Connect a water source to the hose and run water through it at moderate pressure. This helps dislodge loose concrete and debris. Continue flushing until the water exiting the hose is relatively clear. This initial flush is vital for removing easily dislodged materials.

Step 2: Mechanical Cleaning

If water flushing doesn’t remove all debris, use a cleaning ball or sponge specifically designed for concrete pump hoses. Insert the cleaning device into the hose and flush it through with water pressure. This mechanical action helps scrape and remove stubborn concrete deposits. Repeat this step as needed to ensure thorough cleaning.

Step 3: Chemical Cleaning (If Necessary)

For hardened concrete, use a specialized concrete dissolving chemical. Follow the manufacturer’s instructions for dilution and application. Pour the chemical solution into the hose and allow it to sit for the recommended time to break down the hardened concrete. Then, flush the hose thoroughly with clean water to remove chemical residues.

Step 4: Final Water Flush and Inspection

Perform a final water flush to ensure all remaining debris and chemical residues are removed. Inspect the hose for any damage, such as cracks or abrasions. Check the couplings and connections for leaks or wear. Ensure the hose is completely clean and in good condition before storage or reuse.

You should choose Kingdaflex concrete pump hoses because they are specifically engineered for the demanding conditions of high-pressure concrete pouring. We use premium-grade synthetic rubber for the inner tube, which provides exceptional abrasion resistance to withstand the continuous flow of concrete and aggregates, ensuring a long service life.

Our hoses are reinforced with multiple layers of high-tensile steel wire or polyester cords, giving them a superior pressure rating and burst strength to prevent dangerous blowouts. Additionally, our hoses are designed to be flexible and easy to handle, which improves operator efficiency and safety on the job site.

Superior Abrasion Resistance: Our hoses are made with a special inner tube compound that resists the abrasive nature of concrete, extending the hose’s life and reducing replacement costs.

High Pressure and Safety: Reinforced with multi-ply steel wire, our hoses are built to handle extreme working pressures with a high safety factor, minimizing the risk of ruptures.

Enhanced Flexibility: Despite their strength, our hoses are designed for optimal flexibility, allowing for easy maneuverability and placement in tight or hard-to-reach areas.

Reliable Construction: Every hose is meticulously engineered and rigorously tested to ensure it delivers consistent performance and reliability under the toughest conditions.

Cost-Effective Solution: By offering durable and long-lasting products, we provide a cost-effective solution that reduces downtime and operational expenses for your projects.