Selecting the correct rubber hose is crucial for optimal performance and longevity in various applications. EPDM and nitrile are two popular choices, each offering distinct advantages. Understanding their properties is essential to making an informed decision. This blog delves into the key differences between EPDM and nitrile hoses, helping you determine which material best suits your needs.

Whether you require hoses for hydraulic systems, automotive applications, or industrial fluid transfer, material selection significantly impacts reliability and safety. EPDM excels in outdoor environments due to its superior weather and ozone resistance, while nitrile shines in applications involving oils and fuels. We’ll explore their temperature ranges, chemical compatibilities, and ideal uses to guide your selection process.

What Is EPDM

EPDM, short for Ethylene Propylene Diene Monomer, is a synthetic rubber known for its exceptional resistance to weathering, ozone, UV radiation, and a wide range of chemicals. This versatile elastomer maintains its flexibility and durability across a broad temperature spectrum, making it highly suitable for outdoor applications and harsh environmental conditions. Its saturated polymer backbone provides superior resistance to degradation compared to unsaturated rubbers.

What Is EPDM for Hydraulic Hose

EPDM, or Ethylene Propylene Diene Monomer, is a synthetic elastomer that finds specialized use in hydraulic hoses where environmental resistance is paramount. While not as universally applicable as nitrile, EPDM’s unique properties make it suitable for specific hydraulic systems. Its primary advantage lies in its exceptional resistance to weathering, ozone, and UV radiation, ensuring longevity in outdoor or harsh environments. This makes EPDM hoses a reliable choice for applications exposed to the elements.

However, it’s crucial to note that EPDM’s compatibility with hydraulic fluids is limited. It’s not suitable for petroleum-based hydraulic oils, which are common in many hydraulic systems. Instead,

EPDM hoses are typically used in systems employing phosphate ester-based fluids or water-based hydraulic fluids. Their ability to withstand a wide temperature range and resistance to certain chemicals further enhances their suitability in these specialized applications. Therefore, EPDM is a niche but valuable material for hydraulic hoses in specific operating conditions.

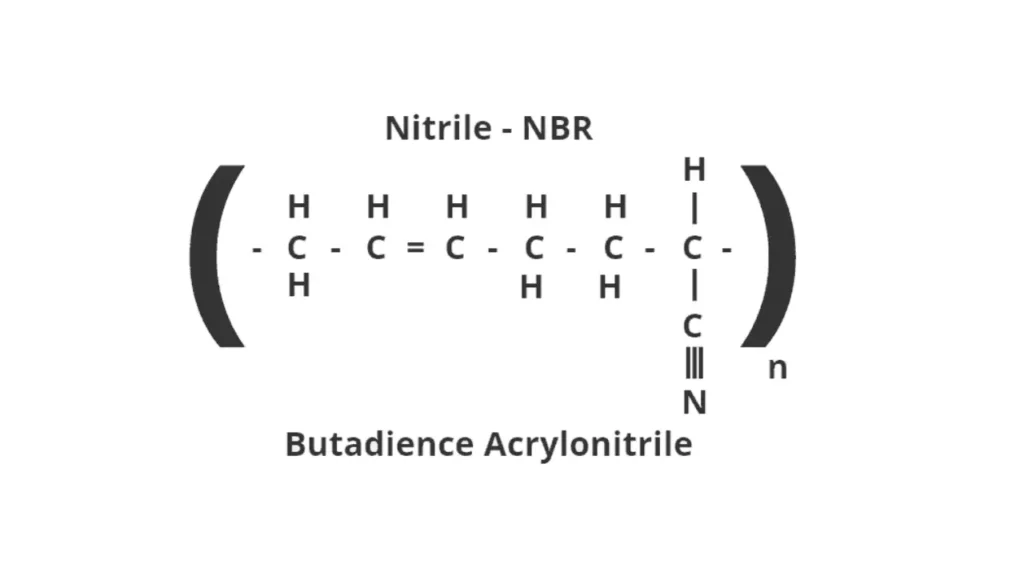

What Is Nitrile

Nitrile rubber, also known as NBR (Nitrile Butadiene Rubber), is a synthetic rubber copolymer of acrylonitrile and butadiene. It’s highly valued for its excellent resistance to oils, fuels, and other petroleum-based fluids, making it a preferred material in applications involving hydrocarbons. Nitrile also exhibits good abrasion resistance and tensile strength, contributing to its durability in demanding industrial environments.

What Is Nitrile for Hydraulic Hoses

Nitrile rubber, also known as NBR (Nitrile Butadiene Rubber), is a widely favored material for hydraulic hoses due to its exceptional resistance to petroleum-based fluids. This makes it ideal for applications involving mineral oils, hydraulic fluids, and other hydrocarbons commonly used in hydraulic systems. Nitrile hoses provide reliable performance and longevity in demanding industrial environments where fluid compatibility is critical.

Nitrile’s advantages extend beyond fluid resistance. It also exhibits good abrasion resistance and tensile strength, contributing to the hose’s durability under high-pressure conditions. This makes it suitable for heavy-duty hydraulic applications where hoses are subjected to significant mechanical stress. However, it’s important to note that nitrile is less resistant to weathering and ozone compared to EPDM.

Therefore, it’s primarily used in indoor or protected environments where exposure to these elements is minimized. Nitrile’s specific properties make it a cornerstone material for hydraulic hoses in a wide range of industrial applications.

EPDM vs Nitrile Hydraulic Hose

When choosing between EPDM and nitrile for hydraulic hoses, the decision hinges on the specific operating conditions and fluid compatibility requirements. EPDM excels in environments demanding resistance to weathering, ozone, and UV radiation, making it ideal for outdoor hydraulic systems or those utilizing water-based or phosphate ester fluids. Its wide temperature range further enhances its versatility in challenging settings.

EPDM Advantages:

- Excellent weathering and ozone resistance.

- Good temperature flexibility.

- Suitable for water-based and phosphate ester hydraulic fluids.

- Ideal for outdoor applications.

Nitrile, conversely, is the preferred choice for applications involving petroleum-based hydraulic fluids, mineral oils, and other hydrocarbons. Its superior resistance to these fluids, coupled with good abrasion resistance and tensile strength, ensures reliable performance in demanding industrial settings. However, nitrile’s lower resistance to weathering and ozone limits its suitability for prolonged outdoor exposure.

Nitrile Advantages:

- Superior resistance to mineral oils and petroleum-based fluids.

- Good abrasion resistance and tensile strength.

- Suitable for high-pressure hydraulic systems using mineral oils.

- Ideal for indoor industrial applications.

Ultimately, the selection between EPDM and nitrile depends on the balance of environmental factors and fluid compatibility. For outdoor applications or systems using water-based fluids, EPDM provides optimal performance. For indoor applications or systems using mineral oils, nitrile is the superior choice.

| Feature | EPDM | Nitrile |

| Oil Resistance | Poor | Excellent |

| Weather Resistance | Excellent | Poor |

| Temperature Range | Wide | Moderate |

| Fluid Compatibility | Water-based, Phosphate Ester | Petroleum-based |

| Abrasion Resistance | Moderate | Good |

| Tensile Strength | Moderate | Good |

| Ideal Application | Outdoor, Water-based systems | Indoor, Oil-based systems |

How to Choose the Best EPDM and Nitrile Hydraulic Hose

Selecting the optimal EPDM or nitrile hydraulic hose requires a thorough understanding of your application’s specific needs. Begin by evaluating the operating environment and the types of fluids the hose will encounter.

If the hydraulic hose will be exposed to outdoor conditions, ozone, or UV radiation, EPDM is the preferred choice due to its superior weathering resistance. For systems utilizing petroleum-based hydraulic fluids, mineral oils, or other hydrocarbons, nitrile provides unmatched fluid compatibility. Next, consider the operating temperature range and pressure requirements of your hydraulic system. Ensuring the hose’s specifications align with these parameters is critical for safety and performance.

Key Selection Factors:

- Fluid Compatibility: Match the hose material to the specific hydraulic fluid.

- Operating Temperature: Select a hose rated for the system’s temperature range.

- Pressure Rating: Ensure the hose’s pressure rating exceeds the system’s maximum pressure.

- Environmental Exposure: Consider weather, ozone, and chemical exposure.

- Application-Specific Needs: Factor in abrasion resistance, flexibility, and other unique requirements.

Ultimately, the decision between EPDM and nitrile hinges on a careful assessment of these factors. Consult our manufacturer specifications and seek expert advice to ensure you choose the most suitable hydraulic hose. Proper selection minimizes the risk of premature hose failure and ensures the safe and efficient operation of your hydraulic system.

Conclusion

In the industry rubber hydraulic hoses, EPDM and nitrile serve distinct purposes, each excelling in specific environments. EPDM’s resilience against weathering and ozone makes it ideal for outdoor applications and water-based systems. Conversely, nitrile’s superior resistance to oils and fuels positions it as the prime choice for hydraulic and fuel-related tasks. Understanding these core differences is crucial for optimal hose selection.

Ultimately, the right hose depends on your application’s unique demands. Consider operating temperatures, fluid compatibility, and environmental factors to ensure longevity and performance. Proper material selection minimizes risks and maximizes efficiency, preventing costly downtime and ensuring safe operations. Both materials offer valuable attributes, catering to diverse industrial needs.

For reliable wholesale hydraulic hoses, including EPDM and nitrile options, partner with Kingdaflex. We offer high-quality hoses designed for demanding applications, ensuring superior performance and durability. Contact us today for a tailored quote and experience the Kingdaflex difference in quality and service.