Ready to enhance safety and protect your assets from extreme temperatures? Sourcing fire retardant sleeves from China offers a strategic advantage, combining competitive pricing with access to advanced manufacturing capabilities. You can secure a reliable supply of high-performance sleeves designed to meet rigorous international safety standards.

Competitive Pricing: Benefit from the cost-effectiveness of Chinese manufacturing, allowing you to purchase high-quality fire retardant sleeves at a significantly lower price point without compromising on essential safety features.

Diverse Product Range: Explore a vast selection of materials and sizes to match any application, from aerospace and automotive to heavy industrial equipment. Find the perfect sleeve for your specific heat protection needs.

Customization Options: Many Chinese suppliers offer extensive customization services, enabling you to specify unique dimensions, colors, and branding for your sleeves, ensuring they perfectly integrate with your products or systems.

Compliance with Standards: Our partners manufacture sleeves that adhere to strict international fire safety regulations and quality control standards, guaranteeing your product provides dependable and certified protection against high temperatures and flames.

As a premier Fire Retardant Sleeve manufacturer from China, we specialize in high-performance thermal protection solutions for the global market. Our sleeves are engineered with premium-grade silicone and fiberglass to withstand extreme temperatures, molten splash, and fire. We are committed to delivering reliable, cost-effective products that enhance safety and extend the life of your critical hydraulic and electrical components.

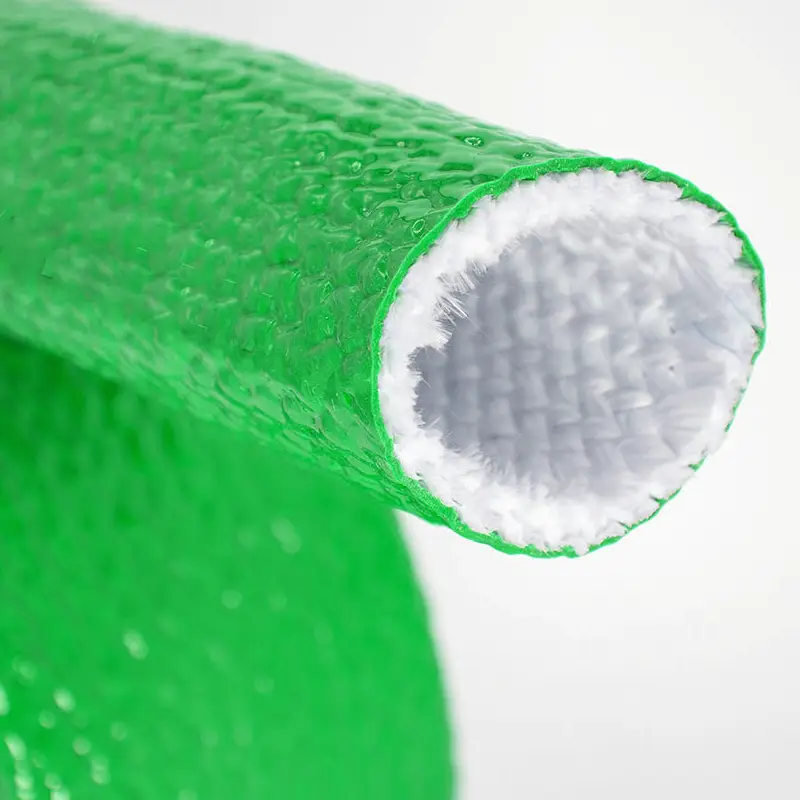

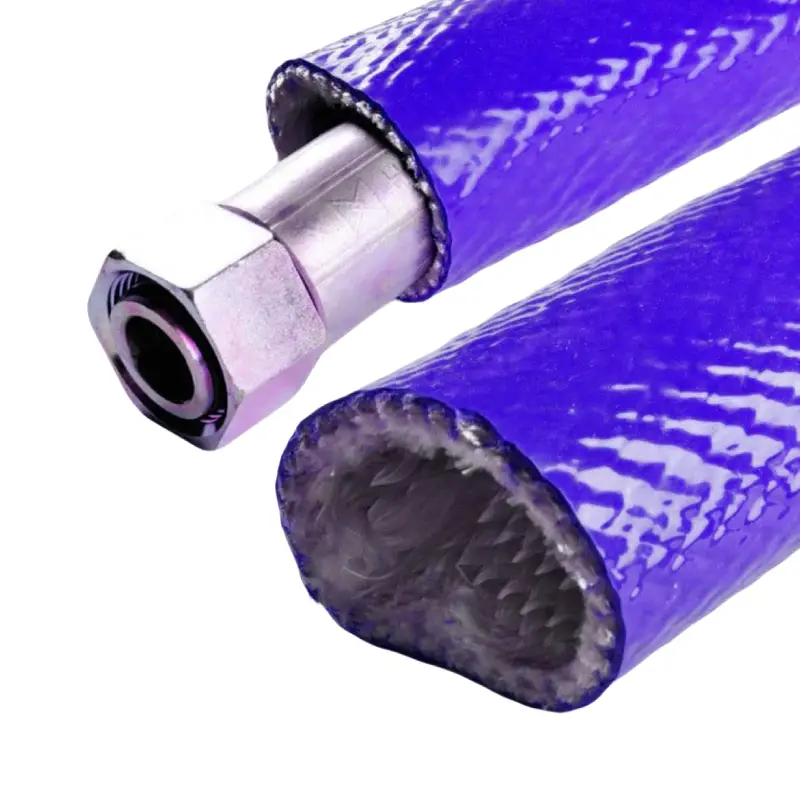

Inner Core: This layer is typically a braided or knitted tube of high-temperature resistant fiberglass yarn. It forms the primary thermal barrier and provides the sleeve’s structural integrity, allowing it to withstand continuous high temperatures.

Outer Coating: The fiberglass core is heavily coated with a specialized silicone rubber. This outer layer provides the sleeve with its superior fire resistance, repelling molten metal splash, resisting abrasion, and offering protection from oils, moisture, and chemicals.

Optional Fasteners: Some fire retardant sleeves are designed with a closure mechanism, such as hook-and-loop fasteners (Velcro) or zippers. This allows for a “retro-fit” installation, making it possible to wrap the sleeve around existing hoses and cables without having to disconnect them.

Enhanced Safety and Fire Protection: These sleeves act as a crucial barrier, preventing hoses and cables from igniting or contributing to a fire. They protect against extreme heat, direct flame, and molten metal splash, allowing more time for emergency response and evacuation by preventing fire from spreading.

Extended Component Lifespan: By insulating and protecting critical lines from high temperatures, UV radiation, and external abrasion, fire retardant sleeves significantly extend the operational life of hydraulic hoses, wires, and cables, reducing the frequency of costly replacements.

Improved Operational Reliability: A fire or component failure can lead to significant downtime and financial loss. These sleeves ensure that your critical systems, especially those carrying flammable fluids, remain functional and reliable under harsh conditions, maximizing uptime and productivity.

Personnel Protection: Beyond safeguarding equipment, fire retardant sleeves also protect workers from potential burns. They act as a thermal barrier, reducing the surface temperature of hot pipes and hoses, and can contain leaks of hot or volatile fluids, preventing serious injury.

We specialize in manufacturing high-performance fire retardant sleeves designed for superior thermal protection. Our sleeves, made from a premium-grade fiberglass and silicone compound, shield hydraulic hoses, cables, and wires from extreme heat, direct flame, and molten metal splash. We offer a reliable and durable solution to enhance safety and extend the life of your critical components.

We offer premium silicone-coated fire retardant sleeves engineered for superior thermal protection. Our sleeves are crafted from high-temperature fiberglass coated with heavy-duty silicone rubber, providing exceptional resistance to extreme heat, fire, and molten splash. This design ensures the safety and longevity of your hydraulic hoses, cables, and wires in the most demanding environments.

We offer a range of colored fire retardant hose sleeves, providing both superior thermal protection and easy color-coding for your systems. Our premium silicone-coated fiberglass sleeves shield hoses from extreme heat and molten splash. The vibrant colors simplify identification of different lines, enhancing safety and maintenance efficiency on your equipment.

We offer premium fire retardant hydraulic hose sleeves, meticulously engineered to protect your critical systems. Made with a high-temperature silicone coating over braided fiberglass, our sleeves provide exceptional resistance to extreme heat, flames, and molten splash. This crucial layer of protection enhances safety, prevents costly failures, and extends the service life of your hydraulic hoses in hazardous environments.

Want a fire retardant sleeve that fits your exact specifications? We understand that every application is different, and a one-size-fits-all approach isn’t always the safest or most effective solution. That’s why we offer extensive customization services, working closely with you to design a thermal protection sleeve that meets your specific needs for enhanced safety and performance.

We can produce fire retardant sleeves in a precise diameter and length to perfectly fit your hoses, cables, or wires. This custom sizing ensures a snug, secure fit, maximizing thermal protection and preventing a loose fit that could lead to wear. This also eliminates the need for excess cutting and reduces installation waste.

We offer a variety of color options for the silicone coating, allowing you to match the sleeve to your company’s branding or to color-code different lines for easy identification. We can also add your company logo or product name directly onto the sleeve, enhancing brand recognition and professionalism.

For a polished and secure fit, we provide custom end finishing options. This includes vulcanized ends for a clean, sealed finish that prevents fraying, as well as the integration of various fittings or clamps. This ensures the sleeve remains securely in place even under high vibration and stress.

We can integrate different fastening methods into the sleeve design to accommodate your installation needs. Whether you prefer a retro-fit design with a secure hook-and-loop closure for easy installation on existing lines or a traditional pull-on style, we can provide the perfect solution for your application.

The manufacturing of fire retardant sleeves is a specialized process that combines high-temperature-resistant materials to create a durable and effective thermal barrier. This process ensures the sleeve can withstand continuous heat, direct flame, and molten metal splash while remaining flexible for easy installation.

Material Preparation: We source high-purity fiberglass yarn and mix a specialized silicone rubber compound with additives to create the base materials for the sleeve’s core and coating.

Braiding or Knitting: The fiberglass yarn is braided or knitted into a flexible, tubular core. This forms the sleeve’s thermal and structural foundation, controlling density for durability.

Silicone Coating: The braided core is passed through a coating line to apply a thick, uniform layer of the prepared silicone rubber, which provides the critical fire and splash resistance.

Curing and Vulcanization: The coated sleeve is heated in an oven to permanently bond the silicone to the fiberglass. This vulcanization process ensures the sleeve’s long-lasting durability and performance.

Final Processing: After curing, the sleeve is cooled, cut to size, and may have fasteners added for easy installation. A final inspection ensures quality before packaging for shipment.

A drilling hose, also known as a rotary drilling hose or vibrator hose, is a high-pressure, flexible pipeline used on drilling rigs. Its primary function is to connect the standpipe to the swivel, enabling the transfer of high-pressure drilling fluids (or “mud”) from the mud pumps down to the drill bit.

These drilling hoses are specifically engineered to withstand the extreme pressures, temperatures, and abrasive fluids encountered in oil and gas drilling, geological exploration, and other industrial applications, ensuring safe and efficient operations.

Drilling hoses are composed of multiple layers of specialized materials, with each layer serving a critical function to ensure the hose’s durability, flexibility, and safety under extreme conditions.

The entire assembly is designed to withstand the high pressures, temperatures, and abrasive fluids common in drilling operations.

Inner Tube: The innermost layer is typically made of high-quality synthetic rubber, such as Nitrile Butadiene Rubber (NBR) or Viton. This material is selected for its excellent resistance to abrasion, corrosion, and the various oils and chemicals present in drilling mud.

Reinforcement: This is the core structural component, providing the hose with its high-pressure rating. It consists of multiple layers of spiraled high-tensile steel wire or steel cables. This spiraled design allows for both immense strength and the flexibility needed on a moving drill rig.

Outer Cover: The outermost layer is made from a durable, heavy-duty synthetic rubber, often chloroprene rubber. This cover protects the inner layers from external damage, including abrasion, cuts, weather, ozone, sunlight, and aging, significantly extending the hose’s service life.

Drilling hoses are multi-purpose, high-pressure conduits essential for a wide range of industrial applications, primarily within the oil, gas, and mining sectors.

Their main function is to facilitate the transfer of various high-pressure fluids and slurries, ensuring the efficiency and safety of drilling and well-servicing operations.

Drilling Operations: They are primarily used to convey high-pressure drilling fluids (mud) from the rig’s mud pumps to the rotating drill bit, where the mud cools the bit, lubricates the drill string, and carries rock cuttings to the surface.

Well Cementing: These hoses are critical for pumping high-pressure cement slurry down the wellbore to secure the casing and prevent fluid migration between different geological zones.

Geological and Mineral Exploration: They are employed in both land-based and offshore exploration to circulate drilling mud and water, allowing for the collection of core samples and analysis of subsurface geology.

Water Conveyance: In mining and other industrial settings, drilling hoses are used for high-pressure water delivery, such as for coal excavation or dewatering projects.

Drilling hoses are multi-purpose, high-pressure conduits essential for a wide range of industrial applications, primarily within the oil, gas, and mining sectors. Their main function is to facilitate the transfer of various high-pressure fluids and slurries, ensuring the efficiency and safety of drilling and well-servicing operations.

Oil and Gas Drilling: They are primarily used to convey high-pressure drilling fluids (mud) from the rig’s mud pumps to the rotating drill bit, where the mud cools the bit, lubricates the drill string, and carries rock cuttings to the surface.

Well Cementing: These hoses are critical for pumping high-pressure cement slurry down the wellbore to secure the casing and prevent fluid migration between different geological zones.

Geological and Mineral Exploration: They are employed in both land-based and offshore exploration to circulate drilling mud and water, allowing for the collection of core samples and analysis of subsurface geology.

Water Conveyance: In mining and other industrial settings, drilling hoses are used for high-pressure water delivery, such as for coal excavation or dewatering projects.

Choosing our drilling hoses means investing in a product engineered for peak performance and safety in the most demanding environments. We are a leading manufacturer committed to excellence, providing hoses that are API 7K certified and designed to maximize uptime while protecting your team and assets.

Our commitment to quality, combined with our global logistics network, ensures you receive a reliable product when and where you need it.

API 7K Certified: Our hoses meet the highest industry standards, ensuring superior quality, performance, and safety for all drilling applications.

Engineered for Durability: Constructed with premium materials and reinforced with high-tensile steel, our hoses resist extreme pressure, abrasion, and harsh fluids, significantly extending their service life.

Reliable Performance: Designed to handle intense pressures and temperatures, our hoses provide consistent fluid transfer, reducing the risk of costly failures and operational downtime.

Global Logistics: With a streamlined supply chain, we can deliver our high-quality hoses to your location efficiently, ensuring your operations remain on schedule.