When we talk about hydraulic systems, the unsung hero often overlooked is the hydraulic fluid itself. It’s more than just a liquid; it’s the very power source that allows machinery to lift, push, and pull with incredible force. But what exactly is this vital fluid, and what makes it suitable for transmission through your system’s hydraulic hoses?

This blog will delve into the fascinating world of hydraulic fluid, exploring its key properties and the crucial role it plays in efficient power transfer. We’ll specifically focus on how these specialized fluids are precisely what your hydraulic hoses are designed to convey, ensuring smooth and powerful operation of your equipment.

What is Hydraulic Fluid?

Hydraulic fluid, often referred to as hydraulic oil, is the essential medium by which power is transmitted in hydraulic machinery. This specialized fluid is largely incompressible, allowing it to efficiently transfer force and pressure from one point to another within a system.

Beyond its primary role in power transmission, hydraulic fluid also serves as a lubricant for moving parts, a coolant to dissipate heat generated by friction, and a sealant to prevent internal and external leaks, all contributing to the smooth and effective operation of a hydraulic system.

What is Hydraulic Fluid Made Of?

Hydraulic fluid is a carefully engineered substance designed to transmit power, lubricate, cool, and seal within a hydraulic system. Its composition primarily consists of a base fluid, which dictates its fundamental properties, combined with a sophisticated blend of additives that enhance its performance for specific applications.

The base fluid can vary significantly, leading to different categories of hydraulic fluid.

Here are the main components hydraulic fluid is made of:

Base Fluid:

- Mineral Oil: Derived from petroleum, this is the most common base fluid due to its cost-effectiveness and good general performance.

- Synthetic Oil: Chemically engineered compounds offering superior performance in extreme temperatures, oxidation resistance, and longer service life.

- Water-Based: Mixtures of water with glycols or esters, primarily used for fire resistance in hazardous environments.

- Vegetable Oils: Biodegradable options for environmentally sensitive applications.

Additives: These are crucial chemicals, typically making up 2-5% of the fluid, that enhance various properties:

- Anti-wear agents: Form a protective layer on metal surfaces to reduce friction and wear.

- Rust and Corrosion Inhibitors: Protect metal components from rust and corrosive degradation.

- Viscosity Index Improvers: Maintain stable fluid viscosity across a wide range of temperatures.

- Antioxidants: Prevent fluid degradation and sludge formation due to oxidation, extending fluid life.

- Antifoaming Agents: Minimize the formation of air bubbles, which can cause cavitation and reduce efficiency.

- Detergents and Dispersants: Keep the system clean by preventing the buildup of deposits and suspending contaminants.

- Pour Point Depressants: Improve fluid flow at low temperatures.

What Type of Hydraulic Fluid for Hydraulic Hoses?

Selecting the correct type of hydraulic fluid is crucial for the longevity and performance of your hydraulic hoses and the entire system. Different applications and operating conditions demand specific fluid properties to ensure efficient power transfer, lubrication, and system protection. Understanding these types ensures compatibility and optimal performance.

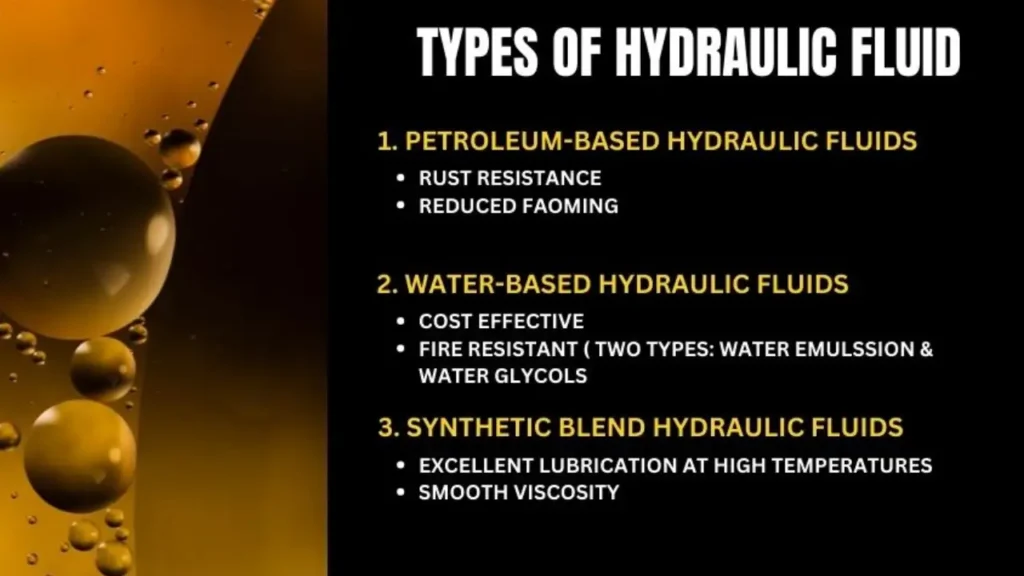

Here are some common types of hydraulic fluid suitable for hydraulic hoses:

- Mineral-Based Hydraulic Fluids: These are the most common and cost-effective type, derived from petroleum. They offer good lubrication, corrosion protection, and a wide operating temperature range. They are generally compatible with standard rubber hoses and seals, making them suitable for many industrial and mobile applications.

- Synthetic Hydraulic Fluids: Engineered for extreme conditions, synthetic fluids offer superior thermal stability, oxidation resistance, and performance at very high or low temperatures. While more expensive, they can extend component life and reduce maintenance. They require specific hose materials, as some synthetics can degrade standard rubber.

- Biodegradable Hydraulic Fluids: Designed for environmentally sensitive applications, these fluids are often vegetable oil-based or synthetic esters that decompose naturally. They are crucial for equipment operating near water or in agricultural settings. Compatibility with hose materials is critical, as some biodegradable fluids can be aggressive towards conventional seals.

- Fire-Resistant Hydraulic Fluids (FRHF): Used in environments where fire hazards are present, such as steel mills or die-casting operations. These include water-glycol, phosphate esters, or polyol esters. Their chemical composition requires specific hose materials designed to resist their often aggressive nature, preventing premature hose failure and leaks.

How to Check Hydraulic Fluid?

Regularly checking your hydraulic fluid is vital for maintaining the health and efficiency of your hydraulic system and ensuring the longevity of your hydraulic hoses. Proper fluid levels and quality prevent cavitation, overheating, and premature component wear, all of which can severely impact hose integrity.

Step 1: Prepare for Inspection

Before checking the fluid, ensure the hydraulic system is completely off and cool. This prevents injury from moving parts or hot fluid. Position the machinery on level ground to get an accurate reading, as an uneven surface can lead to misleading fluid level indications in the reservoir.

Locate the hydraulic fluid reservoir, which is typically a tank with a sight gauge or dipstick. Have a clean, lint-free cloth and a funnel ready, along with a container for any excess fluid. Safety glasses and gloves are recommended to protect against splashes.

Step 2: Check Fluid Level

Use the dipstick or sight gauge to assess the fluid level. Most systems have indicators for “full” or an acceptable operating range. If the level is below the minimum, add the recommended type of hydraulic fluid slowly, being careful not to overfill, which can cause aeration and pressure issues.

An abnormally low fluid level often indicates a leak within the system, potentially from a compromised hydraulic hose. Visually inspect all hoses and fittings for signs of weeping or dripping fluid, which should be addressed immediately to prevent further fluid loss and system damage.

Step 3: Inspect Fluid Quality

Observe the fluid’s color and clarity. New hydraulic fluid is typically clear and amber. Dark, cloudy, or milky fluid suggests contamination by water, air, or particulate matter, which can accelerate wear on pumps, valves, and critically, internal hose linings.

Look for any foreign particles floating in the fluid or sediment at the bottom of the reservoir. A strong, burnt odor indicates overheating, which can degrade the fluid’s properties and harden hose materials over time. If contamination or degradation is evident, a fluid change and system flush are necessary.

Hydraulic Fluid and Its Crucial Relationship with Hydraulic Hoses

The performance and lifespan of your hydraulic hoses are inextricably linked to the type and condition of the hydraulic fluid they convey. It’s not just about moving fluid; it’s about moving the right fluid for the hose material and maintaining its quality. This critical interaction ensures system efficiency and prevents costly failures.

Fluid Compatibility

One of the most vital considerations is the compatibility between the hydraulic fluid and the inner tube material of the hydraulic hose. Different fluid chemistries, especially those of synthetic or fire-resistant types, can react adversely with certain rubber compounds, leading to softening, hardening, cracking, or swelling of the hose liner.

This degradation severely compromises the hose’s ability to withstand pressure and can result in leaks or catastrophic bursts. Always consult the hose manufacturer’s specifications to ensure the chosen fluid is compatible with the hose material.

Hydraulic Fluid Quality and Hose Longevity

The quality of the hydraulic fluid directly impacts the lifespan of hydraulic hoses. Contaminated fluid, whether by solid particles, water, or air, acts as an abrasive or corrosive agent, accelerating wear on the hose’s inner lining. Overheated or degraded fluid can break down the hose material from the inside, reducing its flexibility and pressure rating. Regular fluid analysis helps detect these issues early, allowing for fluid changes or filtration before hoses are permanently damaged, thereby extending their service life significantly.

Pressure, Flow, and Hydraulic Hose Performance

Hydraulic fluid is designed to transmit pressure and flow through the hoses, and the fluid’s properties play a role here. While the hose’s construction determines its pressure rating, the fluid’s viscosity affects flow efficiency and heat generation. Fluid that is too thick can cause excessive pressure drop and heat buildup within the hose, potentially leading to premature aging.

Conversely, fluid that is too thin might not provide adequate lubrication or sealing, potentially causing internal erosion of the hose material due to high-velocity flow and cavitation. Maintaining the correct fluid viscosity helps ensure optimal flow characteristics and prolongs hose life.

How to Know if Hydraulic Fluid is Compatible for Hydraulic Hoses?

Determining if hydraulic fluid is compatible with your hydraulic hoses is critical for preventing premature hydraulic hose failure, leaks, and system downtime. This compatibility primarily hinges on the chemical interaction between the fluid and the hydraulic hose’s inner tube material, which can be negatively affected by factors like temperature and fluid degradation over time.

Ensuring proper compatibility is a non-negotiable step in maintaining a safe and efficient hydraulic system.

Here’s how to know if hydraulic fluid is compatible for hydraulic hoses:

- Consult Manufacturer’s Data and Chemical Compatibility Charts: The most reliable way is to refer to the hydraulic hose manufacturer‘s specifications and chemical resistance charts. These charts explicitly list which fluid types and specific fluid brands are compatible with particular hose materials (e.g., Nitrile, EPDM, PTFE) across different temperature ranges, often using a rating system like “Excellent,” “Good,” or “Not Recommended.”

- Check the Hose Layline: Often, the hydraulic hose’s layline (the printed information along its length) will indicate the hose series or material type. You can then cross-reference this information with the manufacturer’s compatibility data. Some laylines may even directly state compatible fluid types, simplifying the selection process.

- Understand Fluid Type and Base Chemistry: Know the base chemistry of your hydraulic fluid (e.g., petroleum-based, synthetic, water-glycol, phosphate ester, biodegradable). Different hose materials are designed to resist specific chemical compositions. For instance, hoses designed for petroleum-based fluids may degrade rapidly when exposed to fire-resistant synthetic fluids, and vice versa.

- Consider Operating Temperature: Even if a fluid and hose material are chemically compatible at room temperature, compatibility can change drastically at higher or lower operating temperatures. Always ensure the hose’s rated temperature range is suitable for both the fluid’s operating temperature and the ambient environment, as high temperatures can accelerate chemical reactions and material degradation.

- Observe for Signs of Incompatibility: If a hose is incompatible with the fluid, signs of degradation will eventually appear. These can include softening or hardening of the hose, swelling or shrinking of the inner tube, cracking, blistering, discoloration of the fluid or hose, and fluid weeping through the hose wall. Any of these signs indicate a severe compatibility issue.

Conclusion

Ultimately, the type of hydraulic fluid you use directly impacts the efficiency, longevity, and safety of your entire hydraulic system. Understanding the specific properties and functions of these fluids, and how they interact with your hydraulic hoses, is paramount for optimal performance. It’s not just about any liquid; it’s about the right fluid for the right job, delivered effectively.

The seamless transfer of power relies heavily on both the quality of your hydraulic fluid and the integrity of the hydraulic hoses that convey it. Choosing the correct fluid ensures your system operates smoothly, minimizes wear and tear, and prevents costly downtime. It’s a critical decision that underpins the reliability of your machinery.

For a reliable and robust solution to deliver your hydraulic fluids throughout your system, consider wholesale hydraulic hoses from Kingdaflex. Our hoses are engineered to convey a wide range of hydraulic fluids, ensuring peak performance and durability for your hydraulic applications. Partner with Kingdaflex for your hydraulic hose needs.