Hydraulic systems are the backbone of many industrial and mobile applications, powering everything from heavy machinery to precision manufacturing equipment.

The hydraulic hoses are at the heart of these systems, which play a critical role in the safe and efficient transfer of pressurized fluid. However, hydraulic hoses are not immune to failure, and understanding the common reasons for their demise is crucial for maintaining the reliability and longevity of your hydraulic systems.

In this comprehensive guide, we will delve into the top 9 reasons why hydraulic hoses fail, providing you with the knowledge and insights needed to proactively address these issues and optimize the performance of your hydraulic equipment.

Why Hydraulic Hose Broken

Proper hose selection, installation, routing, and maintenance are crucial to preventing these common failure modes and ensuring the reliable operation of hydraulic systems.

Hydraulic Hose Failure Analysis

Here is the comprehensive guide about hydraulic hose failure analysis, exploring the various investigative techniques and factors to consider:

Gathering Evidence

The first step in any failure analysis is a thorough examination of the scene. This involves:

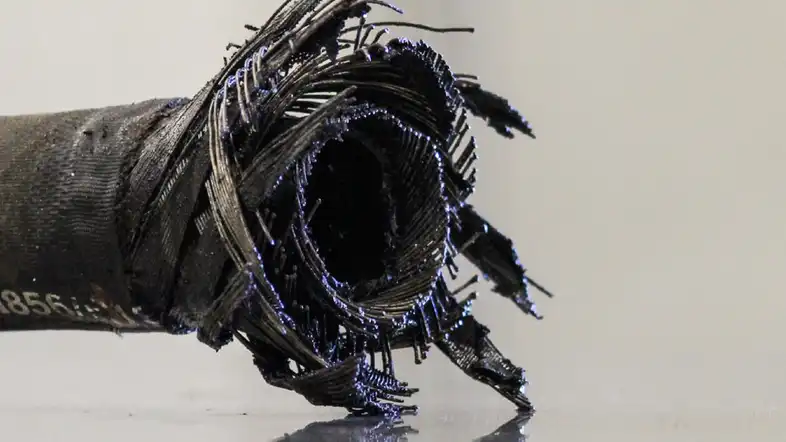

- Visual Inspection: A close inspection of the failed hose is essential. Look for signs of wear, abrasion, cuts, cracks, bulges, or leaks. Note the location of the failure and the type of break (burst, pinhole leak, etc.).

- Collecting Debris: Any debris found near the failed hose, such as metal shavings or rubber fragments, can offer clues about the source of the problem.

- Reviewing System Parameters: Analyze the operating pressure, temperature, and fluid compatibility within the system. Check if these parameters fall within the specifications of the chosen hose.

- Maintenance Records: Review maintenance logs to assess the hose’s age, service history, and any previous repairs or replacements.

Common Causes of Hydraulic Hose Failure

Hydraulic hose failure can stem from various factors, categorized broadly into:

- Manufacturing Defects: While uncommon, hose failures can occur due to flaws in the manufacturing process, such as weak spots or inconsistencies in material thickness.

- Improper Installation: Incorrect hose selection, installation with excessive bending or twisting, or neglecting the minimum bend radius can all lead to premature failure.

- External Damage: Abrasion from contact with moving parts, crushing from objects, or exposure to extreme temperatures can compromise the hose integrity.

- Environmental Factors: Exposure to harsh chemicals, UV radiation, or excessive vibration can accelerate hose degradation.

- Internal Factors: Using incompatible fluids with the hose material or exceeding the pressure rating of the hose can lead to internal damage and eventual failure.

Bringing Science to the Investigation

In some cases, more advanced techniques may be employed to pinpoint the exact cause of failure:

- Pressure Testing: Simulating the operating pressure within the hose can help identify weaknesses or potential leaks.

- Material Analysis: Laboratory analysis of the hose material can reveal signs of degradation or incompatibility with the hydraulic fluid.

- Microscopic Examination: Microscopic examination of the failure site can provide detailed insights into the nature of the break and potential contributing factors.

Preventing Future Failures: Putting the Knowledge to Use

Once the cause of the failure is identified, corrective actions can be implemented to prevent similar occurrences. These may include:

- Implementing a Preventive Maintenance Program: Regular inspections and timely replacement of hoses based on wear and tear can significantly reduce the risk of failure.

- Choosing the Right Hose: Selecting hoses with the appropriate pressure rating, temperature resistance, and material compatibility for the specific application is crucial.

- Proper Installation Techniques: Training technicians on proper installation procedures, including proper routing and avoiding excessive bending, is essential.

- Addressing Environmental Concerns: Protecting hoses from external damage, exposure to harsh chemicals, or extreme temperatures can extend their lifespan.

Hydraulic Hose Failure Reasons

Here are 10 hydraulic hose failure modes you should get to know in the following:

1. Heat causes aging

Hydraulic hoses are designed to withstand high temperatures, but excessive heat can still lead to premature failure. Prolonged exposure to heat causes the rubber compound in the hose to degrade, leading to cracking, hardening, and loss of flexibility.

This can result in leaks, bursts, or the hose becoming too rigid to function properly. Ensuring proper insulation, shielding, and temperature control around hydraulic hoses is crucial to preventing heat-related failures.

2. Poor assembly

Improper installation of hydraulic hoses can significantly impact their lifespan. Incorrect crimping, insufficient tightening of fittings, and using the wrong tools or procedures during assembly can all contribute to leaks and premature failures. Adhering to the manufacturer’s recommended assembly guidelines, using the appropriate tools, and ensuring proper training for personnel responsible for hose installation are essential to preventing assembly-related issues.

3. Poor depth of insertion

The depth to which a hydraulic hose is inserted into a fitting is critical for its performance and longevity. If the hose is not inserted deep enough, the seal between the hose and fitting may be compromised, leading to leaks. Conversely, if the hose is inserted too far, it can damage the internal components of the fitting. Carefully following the manufacturer’s recommended insertion depth during installation is crucial to ensuring a secure, leak-free connection.

4. Failure to meet the minimum bend radius

Hydraulic hoses have a specific minimum bend radius, which is the tightest curve the hose can make without kinking or causing excessive stress on the inner lining. Exceeding this minimum bend radius can lead to premature hose failure due to cracking, weakening of the reinforcement, and reduced flow capacity. Proper routing and the use of bend restrictors or guides can help maintain the hose’s minimum bend radius and extend its service life.

5. Your fluid is incompatible with your tube

The compatibility of the hydraulic fluid with the hose’s inner tube material is essential for the hose’s longevity. Using a fluid that is not compatible with the tube compound can cause the inner lining to swell, soften, or even dissolve, leading to leaks and eventual hose failure. Carefully selecting hoses and fluids that are compatible, as specified by the manufacturer, is crucial to preventing compatibility-related issues.

6. Your routing is off

Proper routing and support of hydraulic hoses are critical to their performance and lifespan. Hoses that are routed too tightly, with excessive bends, or without adequate support are prone to abrasion, kinking, and fatigue failures. Ensuring hoses are routed with gentle curves, provided with sufficient slack, and adequately supported along their length can help prevent routing-related failures.

7. Your tube has been eroded

Hydraulic fluid flowing through the hose can sometimes cause erosion of the inner tube lining, particularly in areas where the fluid experiences high velocity or turbulence. This erosion can thin the tube wall, leading to leaks or even complete hose failure. Factors like fluid viscosity, flow rate, and the presence of contaminants can all contribute to tube erosion. Addressing these factors and using hoses designed to resist erosion can help mitigate this issue.

8. Old, trapped air

Air trapped within the hydraulic system can be a significant contributor to hose failures. As the system operates, the trapped air can cause pressure spikes and cavitation, leading to hose fatigue and eventual bursting. Proper bleeding and purging of the hydraulic system during installation and maintenance can help eliminate trapped air and prevent air-related hose failures.

9. Abrasions

Hydraulic hoses are often routed in environments where they are exposed to abrasive surfaces, sharp edges, or moving components. This can lead to external wear and abrasion of the hose cover, potentially exposing the reinforcement layers and causing hose failure. Protecting hoses with guards, shields, or routing them away from abrasive surfaces can help prevent abrasion-related failures.

By understanding these common reasons for hydraulic hose failures, you can take proactive steps to ensure the longevity and reliability of your hydraulic systems. Regular inspection, proper maintenance, and adherence to manufacturer guidelines can all contribute to minimizing hose-related issues and maximizing the performance and lifespan of your hydraulic equipment.

10. Mechanical Stress

Hydraulic hoses are subjected to various forms of mechanical stress, including tension, compression, torsion, and bending. If the hose is not designed to withstand these stresses or is not properly supported, it can lead to fatigue, cracking, and eventual failure. Ensuring the hose is rated for the specific application and providing adequate support and strain relief.

What Are the Signs of Hose Aging

Here are the key signs of hydraulic hose aging:

Cracking or checking:

As the hose ages, the rubber compound can start to crack or develop a checkered pattern on the surface. This indicates the material is becoming brittle and losing flexibility.

Hardening or softening:

Over time, the hose material can either harden and become less flexible, or soften and become more pliable. Both are signs of material degradation.

Discoloration:

Hoses may start to change color, often becoming darker or more discolored, as the rubber compound breaks down.

Abrasion or wear:

The outer cover of the hose can become worn, abraded, or cracked due to exposure to the environment, vibration, or rubbing against other surfaces.

Bulging or ballooning:

As the inner tube degrades, it can start to bulge or balloon out, indicating a loss of structural integrity.

Weeping or seeping:

Small amounts of fluid seeping or weeping from the hose surface can signify that the reinforcement layers or fittings are starting to fail.

Reduced flexibility:

As the hose ages, it may become stiffer and less flexible, making it harder to route and connect properly.

Regularly inspecting hydraulic hoses for these signs of aging can help identify issues before they lead to catastrophic failures. Proactive replacement of aging hoses is crucial for maintaining the safety and reliability of hydraulic systems.

Conclusion

Understanding these 10 hydraulic hose failure modes is crucial for ensuring the safety and longevity of your hydraulic systems. By implementing regular inspections, proper routing, and selecting the right hoses for your application, you can significantly reduce the risk of costly failures and downtime.

For high-quality, durable hydraulic hoses, choose Kingdaflex. We offer a wide range of wholesale hydraulic hoses designed to withstand demanding applications. Contact us today to learn more about our products and how we can help you optimize your hydraulic system performance.