When it comes to the intricate world of hydraulic systems, one of the most critical aspects often overlooked is the hydraulic hose temperature rating.

These seemingly unassuming components play a pivotal role in maintaining the overall efficiency and safety of your machinery, especially when subjected to varying degrees of heat.

What Role Does Temperature Play in Hydraulic Hoses?

Temperature plays a pivotal role in the performance and longevity of hydraulic hoses. These essential components of hydraulic systems are exposed to a wide range of temperatures due to the nature of their applications. Here’s a closer look at the significant role temperature plays in hydraulic hoses:

Material Integrity:

Hydraulic hoses are typically made from various materials, such as rubber or thermoplastic, each with its own temperature limits. Extreme temperatures, whether excessively hot or cold, can impact the integrity of these materials. Heat can cause the hose material to degrade, leading to cracks, brittleness, and reduced flexibility. Cold temperatures, on the other hand, can make the hose material stiff and less pliable, affecting its ability to function smoothly.

Fluid Viscosity:

Hydraulic systems rely on fluid to transmit power and maintain proper operation. Temperature directly affects the viscosity of the hydraulic fluid. In high temperatures, the fluid may become thinner, affecting its ability to create the necessary pressure within the system. Conversely, in colder temperatures, the fluid can become thicker, potentially impeding its flow through the hoses and causing sluggish operation.

Pressure Variation:

Temperature fluctuations can lead to pressure changes within hydraulic systems. When hydraulic fluid heats up, it expands, which can lead to increased pressure within the hoses. Conversely, cold temperatures can cause the fluid to contract, potentially lowering the pressure. These pressure variations can impact the overall efficiency and functioning of the hydraulic system.

Hose Flexibility:

Hydraulic hoses need to be flexible to accommodate the movements and vibrations of the machinery they’re connected to. Extreme temperatures can affect the hose’s flexibility. In cold temperatures, the hose material might become less pliable, making it challenging for the hose to bend and move with the system. High temperatures can lead to softening of the hose material, potentially causing it to lose its shape and compromise its structural integrity.

Safety Considerations:

Temperature-related issues in hydraulic hoses can have safety implications. For instance, if a hose becomes brittle due to exposure to cold temperatures, it might crack or even rupture under pressure, leading to leaks that could cause equipment damage or injury to operators.

To ensure optimal performance and safety, it’s crucial to select hydraulic hoses with appropriate temperature ratings for the specific operating conditions. Manufacturers provide temperature guidelines for their hoses, allowing users to choose hoses that can withstand the anticipated temperature ranges of their applications. Regular inspections and maintenance are also essential to detect any signs of temperature-induced wear and tear in hydraulic hoses, preventing potential failures and ensuring the continued reliability of hydraulic systems.

Highs and Lows of Temperature Limits

In the intricate realm of hydraulic systems, the concept of temperature limits holds paramount importance. These limits define the temperature range within which hydraulic hoses can safely and effectively operate. Let’s delve into the highs and lows of temperature limits and their profound impact on hydraulic system performance.

Embracing the Heat

High temperature limits are a testament to the resilience of hydraulic hoses. These hoses are engineered to withstand the scorching temperatures that can arise in demanding industrial environments. When the heat is on, hydraulic hoses with robust high temperature limits rise to the occasion, ensuring consistent fluid flow and system efficiency. Whether it’s the blazing heat of a factory floor or the intense heat generated by heavy machinery, these hoses prove their mettle by maintaining their integrity under extreme conditions.

Confronting the Cold

On the flip side, low temperature limits come into play when hydraulic systems find themselves in chilly surroundings. These limits illustrate the hoses’ ability to remain flexible and operational even in freezing temperatures. Cold weather can cause standard materials to become stiff and unyielding, impeding the hoses’ performance. However, hydraulic hoses designed with low temperature limits can defy the chill, bending and flexing without compromising their structural integrity. This adaptability is essential for ensuring smooth operations in cold climates or refrigerated environments.

The Balance Within

Temperature limits encapsulate the delicate equilibrium between material science and engineering prowess. Hydraulic hoses with wide temperature ranges exhibit a harmonious balance between high and low temperature performance. The intricate blend of materials, reinforcement layers, and design considerations enables these hoses to tackle both scorching heat and freezing cold with equal finesse.

Selecting the Right Fit

Choosing the right hydraulic hose entails understanding the temperature conditions your system will encounter. Will your equipment operate in a sweltering foundry or a frigid warehouse? Assessing these conditions allows you to select hoses with appropriate temperature limits, ensuring seamless functionality throughout the year.

In essence, the concept of temperature limits encapsulates the resilience and adaptability of hydraulic hoses. Whether confronting extreme heat or enduring freezing cold, these hoses serve as the unsung heroes of hydraulic systems, maintaining fluid flow, power transmission, and safety. So, the next time you observe hydraulic machinery in action, remember the critical role temperature limits play in keeping the heart of these systems pumping, regardless of the environmental challenges they face.

Meeting the Gold Standard: Selecting the Right Hose

Now that you’re privy to the significance of temperature ratings and the dance of flexibility, the question arises: how do you choose the ideal hydraulic hose for your system’s needs? Here are some pointers to steer you in the right direction.

Know Your System’s Demands

Understanding the operating conditions of your hydraulic system is paramount. Are you dealing with a system that operates in extreme cold or blistering heat? Tailoring your hose selection to match these conditions ensures smooth operation and longevity.

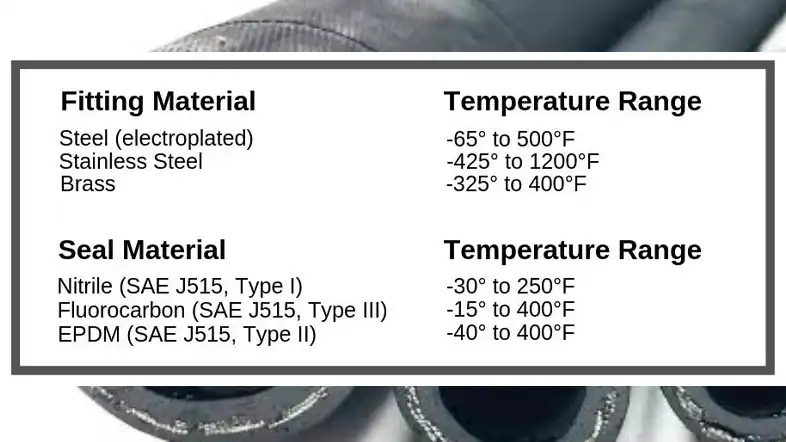

Material Matters

Different materials exhibit varying temperature resistance. Rubber hoses might excel in some temperature ranges, while thermoplastic hoses might conquer others. Consult with experts or manufacturers to determine the best material for your specific environment.

Consider Pressure Ratings

While we’re diving into the complexities of hoses, don’t forget pressure ratings. A hose might handle temperature like a champ, but if it buckles under pressure, your system’s efficiency goes down the drain.

Is Hydraulic Hose Heat Resistant?

Yes, hydraulic hoses are designed to be heat resistant.

These hoses are engineered to withstand a wide range of temperatures, ensuring they can operate effectively even in environments with high heat levels. The heat resistance of hydraulic hoses is crucial because hydraulic systems often involve machinery and equipment that generate heat during operation.

Without proper heat-resistant properties, hoses could degrade, leading to leaks, reduced efficiency, and potential safety hazards.

Hydraulic hose manufacturers carefully select materials and construct hydraulic hoses with temperature ratings that suit different applications, making them capable of handling the heat and maintaining their functionality over time.

Will Hydraulic Hose Work for Coolant?

When it comes to the functionality of hydraulic hoses, their versatility often sparks inquiries about their compatibility with various fluids, including coolants. Hydraulic hoses, engineered to withstand a range of demanding applications, indeed have a role to play in certain coolant systems. Let’s delve into the intricacies of this compatibility and how hydraulic hoses fare when tasked with the responsibility of handling coolant.

Understanding the Coolant Context

Coolants are essential components in various systems, particularly those involving heat-generating machinery or engines. They serve the crucial role of dissipating excess heat, preventing overheating, and maintaining optimal operating temperatures. In applications like automotive engines, industrial machinery, and HVAC systems, coolants are circulated to manage temperature levels and ensure efficient performance.

Hydraulic Hoses’ Composition and Coolant Compatibility

Hydraulic hoses are predominantly constructed using materials like rubber, thermoplastic, or synthetic blends, each chosen for their specific properties. These materials are designed to resist hydraulic fluids, oils, and other substances commonly found in hydraulic systems. When it comes to compatibility with coolants, several factors come into play:

Material Resilience: Many hydraulic hoses are designed to handle a range of fluids, and coolants often fall within this spectrum. The compatibility largely depends on the specific coolant’s chemical composition and its interaction with the hose material. It’s advisable to consult manufacturers’ guidelines to ensure the hose material is suitable for the type of coolant used.

Coolant Composition: Coolants can come in different formulations, including water-based mixtures, ethylene glycol, or propylene glycol blends. Some coolants may contain additives or corrosion inhibitors that could potentially affect the hose material. Compatibility testing or referring to manufacturers’ recommendations can provide clarity on whether a specific hydraulic hose is suitable for a particular coolant.

Temperature Considerations: Coolants, like hydraulic fluids, are subjected to temperature variations. Hydraulic hoses designed for a wide temperature range are more likely to accommodate the temperature fluctuations associated with coolant circulation.

Hose Type:

The type of hydraulic hose matters in compatibility. For instance, hoses with specific lining or barrier layers might be better suited to handle coolants, as they can prevent potential material degradation or contamination.

Consultation is Key

Given the diverse range of hydraulic hoses and coolant formulations available, it’s crucial to consult with manufacturers, hydraulic hose suppliers, or experts in the field to determine the most suitable hose for coolant applications. Compatibility charts, guidelines, and direct consultations can provide insights into which hoses can seamlessly integrate into coolant systems while maintaining their functionality, safety, and durability.

In essence, while not all hydraulic hoses may be suitable for coolant applications, many hoses are designed to handle a variety of fluids, making them potential candidates for coolant systems. Ensuring compatibility, understanding material limitations, and seeking expert advice will ensure that the hydraulic hoses selected can play a pivotal role in effectively managing coolant circulation and contributing to the overall efficiency of the system.

In Conclusion

The next time you glance at your hydraulic system, remember the unsung heroes working tirelessly within—hydraulic hoses with their intricate temperature ratings and flexible burstiness. These components might not be the star of the show, but they ensure the performance, safety, and durability of the entire ensemble.

So, when it comes to selecting the right hydraulic hose, embrace the science of temperature ratings, and let the dance of flexibility lead the way. Your hydraulic system will thank you, as will the efficiency and productivity it brings to your operations.